Stainless seamless pipe: durable products for demanding jobs

When choosing a material for laying communications, which are subject to increased requirements for strength and durability, it is worth exploring such a document as GOST for seamless stainless pipes. It describes the main characteristics of such parts, and provides information on their use.

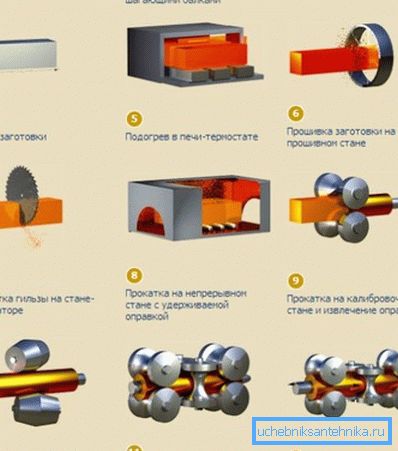

Below we look at the production technology of seamless stainless steel pipes, and also pay attention to their key advantages.

Product Description

Manufacturing method

When laying the most different communications are used steel pipes made of stainless material. And although this steel is quite easy to weld, a significant proportion of all products on the market are made using exactly seamless technology.

Note! The range of such elements is very wide. The most common diameters range from 6 to 630 mm with a pipe wall thickness of 0.5 to 30 mm. In other, the technique allows to produce larger products.

To date, there is a fairly large number of concepts for obtaining tubular billets, but in mass production, either hot or cold deformation is most often used, either by pulling or rolling.

Instructions for the manufacture of hot-rolled pipe includes the following points:

- As a blank, a round, rectangular or multi-faceted bar of steel of the corresponding brand is used.. Rolled billets and products from other alloys can also be used: it is the additional components that provide hardness and resistance to corrosion that largely determines the price of the finished product.

- The pig is heated to the temperature of deformation, after which it is cleaned from scale and cut into separate fragments..

- In the heated bar or cylinder using a special tool - firmware - a starting hole is made. This forms a hollow sleeve with walls of a sufficiently large thickness.

Note! In the manufacture of large diameter parts, a special press can be used instead of a piercing machine.

- Further actions depend on the specific technological scheme.. In one case, the sleeve is sequentially pulled through the calibration dies of different diameters (extrusion process). In another case, the thinning of the walls and the formation of the internal lumen is carried out on a rolling mill.

- Upon completion of these works, the pipe enters the cold calibration section to bring its parameters to a single standard..

- The last step is to trim the part to the size and alignment of the edges..

The elements manufactured according to this scheme are used in arranging distribution systems from water supply, drainage and heating pipes, in thermal installations, in the food industry, etc.

Main varieties and scope

As we noted above, the range of such products is very extensive.

And yet most often in industry use two varieties:

- 12x18H10T - made from austenitic (alloyed with chromium and manganese) steel. The material includes nickel, molybdenum and titanium additives.

- 10x23H18 - made from high-alloy steel billets, can be used in conditions of high temperature (up to 1100 0WITH).

Variety largely determines the scope of the product.

So, the 12x18H10T pipe according to GOST 9941 - 81, which is distinguished by high resistance to any corrosive effects and aggressive media, can be used:

- For the manufacture of functional elements of muffle furnaces.

- In the manufacture of heat exchange equipment.

- As the main element of spark electrodes and spark plugs.

- For laying pipelines of hot and cold water supply, as well as in heating systems (including internal equipment of boiler rooms). The main advantage in this case is the minimal effect on the composition of water, even with prolonged contact. (See also the article Single-pipe heating system: features.)

- In the manufacture of decorative elements: furniture, fences, etc.

The range of application of 10x23H18 products is somewhat narrower:

- Pipes involve in the chemical and petrochemical industry for laying fuel lines.

- Elements are also used in the manufacture of combustion chambers of furnaces and other equipment experiencing increased temperature loads.

In addition to the above, in industry are also used products 10x17H13M2T (calculated on 600 0C, they are distinguished by ease of welding), 06ХН28МДТ (it is characterized by high acid resistance, used in the production of chemical reagents) and other more specific details.

Operational advantages

Analyzing the sphere of operation of pipes of seamless type, made of stainless materials, it is possible to identify a number of obvious advantages:

- First, the lack of a weld seam provides the structure with a maximum margin of safety. Due to the monolithic structure of the walls, the pipe withstands much greater internal pressure without deformations and breaks.

- Secondly, the seamless walls have smooth edges, which provides a much more reliable weld.

- The next plus is provided by the composition of the material itself. The inclusion in steel of various additives allows the use of pipelines in the most aggressive environments for a long time, without fear of corrosion and destruction.

- Titanium and molybdenum additives significantly increase the heat resistance of the pipe. With strong heating, the structure not only does not collapse, but also does not lose strength, while maintaining the tightness of the joints.

- In addition, water in contact with the metal does not change its composition, which is important in the water supply and food industry.

- Finally, such products just look great, especially with appropriate treatment of external surfaces.

Conclusion

When designing a plumbing or heating system with your own hands, it is very important to choose components that correspond to the level of operating loads. And from this point of view, seamless pipelines can be considered one of the most advantageous solutions: yes, they are quite expensive, but the safety factor and long service life makes such a purchase a justifiable investment.

More information on this topic is presented in the video in this article.