Stainless steel chimney pipe: what it is and how to mount it

Chimney only at first glance may seem simple and unimportant design. In fact, not only the normal functioning of the furnace, but also the complete elimination of carbon monoxide depends on its proper operation. With regard to installation, the chimney made of stainless steel can be installed by hand, but should take into account some important details.

Stainless steel chimney options

First you need to talk about the simplest version - about single-layer stainless steel chimney pipes.

The wall thickness in such structures varies from 0.6 to 2 mm and is selected depending on the type of fuel and the length of the system.

- Such constructions can be mounted only in insulated premises.. Often they are installed air or liquid heat exchangers for heating water or buildings.

Important: even taking into account the fact that the price of single-layer pipes is much lower, it is strictly prohibited to install them on the street or in the ceiling. Due to the difference in temperature, the inside of the structure will quickly grow soot. Outside, a big problem will be the settling of condensate on the surface of the chimney and, as a consequence, the dampness of the adjacent materials.

- Stainless steel corrugated chimney pipe is used less frequently.. First, as in the case described above, this design can be installed exclusively in warm rooms. Secondly, the controlling authorities strongly dislike corrugation in smoke extraction systems and experts recommend using hard segments whenever possible.

- The most popular in this market are designs of the so-called sandwich pipes.. Sandwich pipes made of stainless steel for chimneys, are 2 pipes of different diameters, the space between which is filled with heat-resistant insulation.

Subtleties of choice and installation of structures

It is quite simple to install stainless steel chimney by itself, but it is important to do it correctly, taking into account all norms. In order not to redo later.

Choose steel grade

- Stainless steel 430 directly for the chimney fits poorly. It withstands any humidity well, but temperature drops are not desirable for it. Therefore, this brand is used for the outer casing sandwich products.

- For classic wood-burning stoves and fireplaces, brand 409 is more suitable.

- Brand 316 holds good acid and other chemical effects. Its use is advisable when arranging chimneys for gas boilers.

- Steel grade 304, in fact, is a budget equivalent of the brand 316. It almost completely copies all the characteristics of the brand 316, but the price is lower.

- Steel grades 316i or 321 are considered the most common, their temperature limit is 850? С. However, they have good resistance to chemically active compounds.

- Stainless steel chimney pipes made of steel 310S are considered elite. Combining all the advantages of the above listed grades, this metal is able to withstand temperatures up to 1000? С.

Tip: if coking types of coal will be used to operate the furnace, then a 310 S stainless steel chimney will be the best solution.

Installation rates

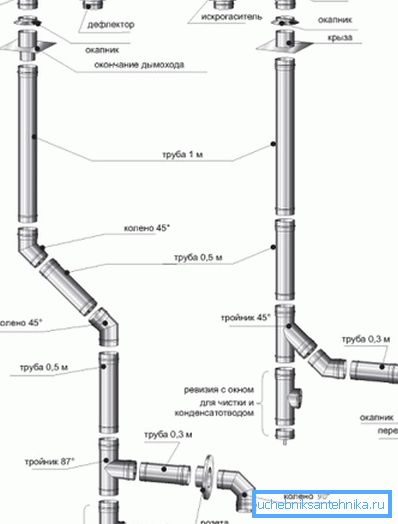

In order to ensure the normal chimney draft, its height must be at least 5m. The length of sections laid horizontally or obliquely should not exceed 1m. Ideally, it is advisable to generally make stainless steel chimney pipes without bends.

According to the standards, installation of such structures in unheated premises or in the open air without thermal insulation is prohibited.

The installation manual recommends paying particular attention to installing the pipe above the roof:

- If the roof is flat, then the pipe should rise above it not less than half a meter.

- The same rule applies to an inclined roof, when the ridge is less than one and a half meters.

- If from a construction to the ridge of a sloping roof from one and a half to 3 m, the pipe cut should be slightly higher or at least at the level of the ridge.

- On large areas, the top of the structure should be above 10? from the level of the horizon along the ridge.

- If auxiliary chambers are attached to the main building of the building, then stainless steel chimneys should in any case be raised above the ridge of the upper building of the complex.

- If the roof or interfloor overlappings are equipped with combustible building materials, then a spark arrester must be built into the system.

- Even for thermally insulated sandwich structures, the distance from them to the interfloor ceilings should be at least 200 mm.

- Docking pipes should not be in monolithic structures, plus the minimum distance from the docking station to walls or floors of 70 cm or more.

- Stainless steel chimneys are inserted into each other, so there are 2 basic rules.

- On inclined or horizontal sections, the line is mounted “by smoke”, so that gases escape without clinging to the joints.

- Vertical sections are mounted “by condensate” so that moisture flows through the pipe without going into the joint.

- No matter how many connections and adapters in the system, not one of them should be less than the outlet from the furnace or boiler. In this case, the chimney can not have more than 3 turns.

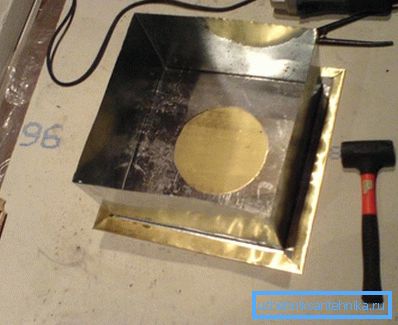

- For the passage of sections of interfloor overlap, special boxes are used, which are filled with expanded clay or other heat-resistant insulation.

A few words about the installation itself

As mentioned earlier, if the route of the chimney is carefully thought out and without fail all permits are obtained in the relevant instances, the installation of a stainless steel chimney pipe will not be difficult. In essence, this is a constructor that is simply going to be elementary.

Important: all seams and joints need to be fluff and sealed with a special compound, it can withstand temperatures up to one and a half thousand degrees and is in any specialized store.

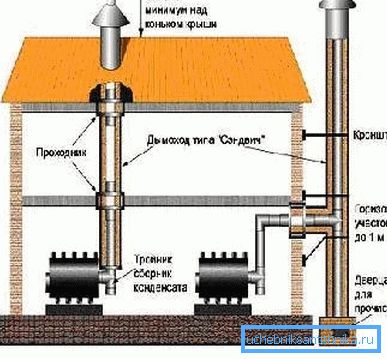

If the structure is mounted on the external wall of the building and is fixed on the wall, the brackets are placed at a distance of no more than 2 m. In the place of transition of the system through the wall, a special support bracket is mounted, which is equipped with a condensate collection compartment.

For interior installation, the main attention should be paid to the passage through the ceiling and fixation on the roof. Leading manufacturers produce special adapter boxes, but even if they are not there, it’s not difficult to do something like this with your own hands. The box itself is filled with thermal insulation.

When passing through the inclined roof, note that the hole is made elliptical. If it is difficult for you to make such an adapter yourself, then it is better to buy a serial, high-quality model. The withdrawal of stainless steel pipes for chimneys through the roof is done in the middle between the supporting rafters of the roof, so that there is a place under the transition duct.

On the roof, it is also important to ensure reliable waterproofing so that no leakage occurs at the docking site. Pipes with a protective skirt are now being produced, the price of such a device is available and it will be useful to buy it.

The whole structure is crowned with an umbrella that protects from precipitation; it often makes sense to place a spark arrestor in this place. Fire protection has never been superfluous.

The video in this article shows some of the subtleties of installation of chimneys.

Conclusion

Stainless steel chimney pipes are a convenient and high-quality element that can be easily mounted with your own hands. The undeniable advantage of such structures is still the possibility of external installation on the wall or as a stand-alone smoke removal system.