Steel electric pipe: parameters and use

In the production of metal structures of different nature, in the automotive industry, construction, industry and even in the production of furniture, steel electric-welded pipes are used according to GOST 10704 91. In addition, such products are well known to oilmen and gas-makers, they are used for water supply and heating - all these industries our weekdays, even if we do not notice.

But such products can not be the same, and this applies not only to the dimensions, but also to other parameters, which, in fact, will be discussed below, and you will see the video in this article, which demonstrates our topic more clearly.

Important about pipes

Note. Along with GOST 10704 91, GOST 10705 80 is also applied to steel electric-welded pipes - both standards are basic when choosing materials for high-pressure pipelines.

The production of electric pipes in Russia is carried out by a fairly large number of factories of plants and factories, among which the Volzhsky Pipe Plant (VTZ) can be distinguished.

The products manufactured by this company are widely demanded for:

- chemical;

- oil and gas;

- automotive industry;

- heat and power engineering;

- as well as for oil and gas pipelines.

The entire assortment is produced in accordance with international and European standards ASTM, APL, EN, DIN and, of course, meets the technical requirements of the Gosstandart of the Russian Federation.

Types and classification

- All steel pipes can be strip (steel sheets), obtained by molding and welding;

- Strip but made by electric welding method;

- Straight-seam, welded parallel to its axis or along a straight joint;

- Electrowelded straight-seam, but cold-rolled;

- Electrowelded straight-seam, but cold-drawn.

For the manufacture of such products are used the so-called strips or steel strips (sheets), welding which is carried out in the factory shop on specialized equipment. Pipes made in this way can have three types of section of the profile, it is a circle, a square and a rectangle.

Also, electric welded pipes can be divided according to physicochemical properties and here there are four main groups:

- Products with the same mechanical properties;

- Products with special chemical compositions;

- Products with special mechanical and chemical properties;

- Products that meet specific hydraulic requirements (high pressure).

Considering the diameters of the steel electrowelded pipe according to GOST 10704 91, according to GOST 3262 75 and GOST 10705-80, it can be dimensional and non-dimensional:

- If the diameter does not exceed 70 mm, then the length can be from 5m to 9m;

- With a cross section of 70 mm to 219 mm, the length can be from 6m to 9m;

- With a cross section of 219 mm to 426 mm, the length can be from 10 m to 12 m.

Note. Products of this type can be produced both with a bevel and without it, which is why the final price upon purchase naturally depends. Wholesale customers usually negotiate this issue directly at the factory.

Electrowelded pipes with different parameters are classified according to the scope of use and here you can select six main purposes:

- For plumbing and heating, as well as for the manufacture of various metal structures - scaffolding, supports for posters and billboards, fences, and the like;

- For water mains, gas and oil pipelines;

- Products of high pressure and increased resistance to temperature changes - food, chemical and nuclear industries;

- In oil exploration;

- Construction equipment, engineering, railway cars;

- Engineering.

Strips

- From English, the word strip is translated as a strip, so the strip means a metal strip, which is used for the manufacture of construction materials, including profiles of rectangular, square and circular cross-section.

- Depending on the further purpose, the strips can be made of simple, stainless and galvanized steel, as well as steel, onto which a specialized polymer coating is applied (plastisol, polymer, prism).

- As a rule, strips are made of thin steel sheets (roll type is possible). The thickness of the manufactured strip can vary between 0.45 mm and 2.0 mm, and its width can range from 25 mm to 1250 mm. This tape has corrosion resistance, ease of use and high strength.

- Strips are used not only for the manufacture of electrically welded pipes, but also for closed / open profiles of very different cross sections, gutters, air ducts, and so on.

Pipe cutting

Electrowelded pipes are cut in various ways and tools, for example, the CASTA lathe that you see in the top photo — products for oil and geological exploration, the mining industry and so on are fragmented in this way (read also the Asbestos Pipe article: features and applications).

In addition, a tape machine is used for cutting - this is for those cases when it is necessary to cut off a fragment directly into a trench or with a general lack of free space.

Machines of this type allow you to cut both round and square and rectangular profiles of black, stainless and galvanized steel. The process itself is as automated as possible and the presence of a person is needed only when loading and unloading the pipes being processed.

The disk line parameters are shown in the table:

| Diameter | mm | 10-100 |

| Cross section of square and rectangular profile | mm | 1010; 6585/1510; 10060 |

| Wall thickness | mm | 1-5 |

| Length | mm | 4000-8000 |

| Cut length | mm | 340-8000 |

| Drive (motor) power for one saw head | kw | 3.3 |

| Disc diameter | mm | 270-350 |

For the installation of pipelines at the construction site, more precisely, for its manning at the workplace, an orbit is used for cutting, which has a small weight and one worker is easily controlled with it. But plasma cutting allows not only to cut the pipe into fragments, but also to chamfer them, which is very convenient, especially for high-pressure lines.

Chamfering

Note. Processing the edge edges of various structural and sheet materials made of metal, made at a certain angle, is called a facet.

Thermal and mechanical methods. Comparison table:

| Method | Thermal withdrawal | Mechanical removal |

| disadvantages | During processing, a thermal influence zone is inevitably formed, that is, the chemical and physical properties of the metal change upon heating. | High labor costs and high cost |

| Benefits | Processing speed and low cost | The almost complete absence of a thermal influence zone, therefore, the metal does not undergo changes in physical and mechanical properties. |

The most common, the cheapest and, at the same time, the most poor quality method can be called gas cutting using propane or acetylene. The fact is that the treated surface does not work out evenly here, but with grooves that remain during heat treatment from gas streams.

But this method has a clear advantage - due to the compactness of the unit, the instruction allows the cutting and processing of fragments directly at the construction site.

Plasma cutting is of very high quality and this method is unlikely for an uninitiated person to be distinguished from mechanical - the cut is clean, without any troughs, chipping and other defects. The unit itself consists of a frame, a compressor and a plasma cutter, which, thanks to the guides on the frame, moves strictly in a circle with the angle of inclination set by the operator.

Mechanical chamfering is carried out in the factory, and the quality of production of this method has no equal, and the dimensions and weight of steel electric welded pipes here have no meaning. The material treated in this way is mainly used for high pressure pipelines in the gas, oil and mining industry.

So what is the purpose of chamfering? This is necessary for the penetration of the metal when performing welding work - if the layer processed by welding is thicker than 3-5 mm, the penetration will be only superficial, therefore, the seam will turn out to be of poor quality.

When the two ends meet, a weld pool is formed, which is filled with the welding compound during the process, but it should be borne in mind that the edge should be blunt (3-5 mm thick) to avoid burning.

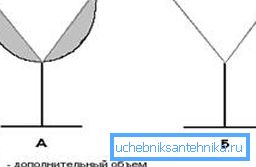

The bevel edge for welding works is cut in three ways - Y-, X- and J-shaped, but sometimes the letters V, K, U, respectively, are used for such designations. As a rule, in most cases, Y- and X-shaped methods are used, and the J-cutting method is used only when there is a need for high quality weld.

It should be noted that the J-shaped way is a curved surface of the chamfer, but it should not be confused with a curved edge - these are completely different planes.

Note. In addition to Y, X and J forms, there are other methods, but they are used extremely rarely, for example, C 14 - broken bevel edges, which is described in GOST 5264-80.

J-chamfer allows you to make the welding joint more qualitative, as it is somewhat rounded (like a glass) - thanks to this rounding, more welding substance falls on the seam. This type of docking in Russia is also called the shot glass method.

Conclusion

In conclusion, it can be said that pipe-rolling production is possible only in factory conditions with modern equipment that ensures the quality of products. Virtually all processes are mechanized and automated, so that people do only welding docking work with their own hands (see also the article Reinforced Polypropylene Pipe: main types and installation technology).