Steel pipe - types and features

Despite the large range of pipes on the building materials market, steel products are still the most popular. They are used in everyday life, in industry, in construction, etc. Of course, pipes for different applications may have different characteristics, so in this article we will look at their types and performance properties.

Classification

The range of steel pipes is very extensive, with the result that there are many options for their classification, in particular by:

- Production method;

- Linear dimensions;

- The availability of coverage, etc.

Next, take a look at them in more detail.

In size

Steel pipe sizes are classified into the following types:

| By section geometry |

|

| Outer diameter |

|

| By lenght | Length can be:

|

| Accuracy class |

|

Note! Standard sizes of steel pipes, including diameters, length, wall thickness, etc., can be found in tables in the reference literature.

By production method

By type of production steel pipe products are divided into:

| Electrowelded |

|

| Seamless |

|

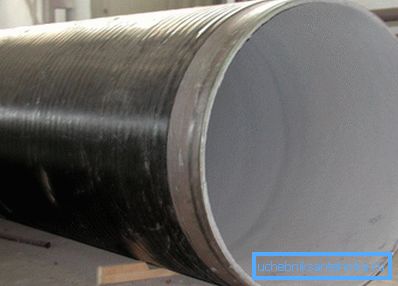

Anti-corrosion protection

Steel is known to be corrosive.

To protect products from this negative phenomenon apply:

- Hot and cold galvanizing;

- Extradited polyethylene;

- Ordinary polyethylene, which is wrapped in pipes in one or more layers.

- Cement-sand mixture;

- Epoxy-bitumen mixture.

Note! The characteristics and properties of the above pipe products are determined by the GOST for steel pipes. Moreover, for each type of pipe has its own GOST.

Special features

Merits

Like any other material, metal pipes have their own advantages and disadvantages.

Among their positive qualities are the following points:

- The service life of 5 - 30 years, depending on the transported liquid and anti-corrosion coating.

- Resistance to high temperatures.

- Incombustible.

- The ability to withstand pressure up to 30 atmospheres (this indicator depends on the type of pipe).

- Resistance to mechanical damage and ductility.

disadvantages

As for the shortcomings, these include:

- Instability to various deposits and corrosion;

- The weight of the steel pipe is much higher than plastic analogues;

- Internal roughness, which creates a strong hydraulic resistance;

- High thermal conductivity;

- The price is higher than the cost of plastic analogues;

- After installation, painting is required.

Areas of use

As mentioned above, the scope of steel pipes are very extensive. Next we give the main ones:

| General Purpose Pipe Products | Used for the following purposes:

|

| Profile | They are widely used in mechanical engineering and various metal structures. |

| Water and gas lines | When installing systems:

|

It should be noted that steel pipes have also found application in the production of furniture, in the automotive industry, aviation, shipbuilding, etc.

Installation Features

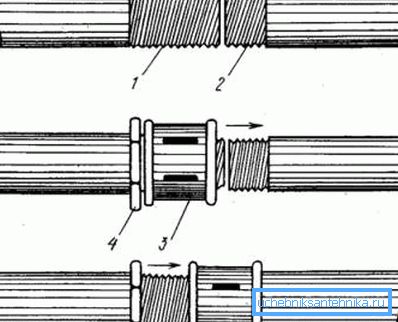

Installation of steel pipes can be carried out in two ways:

- Rezbovym;

- Welded.

A brief instruction for installing the pipeline in a threaded way is as follows:

- A threaded lock nut is screwed onto the end of the threaded pipe.

- Then a coupling is wound on the same thread - a special connecting fitting.

- Further, between the lock nut and the coupling along the thread on the pipe, flax threads are wound, after which the nut is screwed close to the coupling.

- After that, a locknut is screwed onto the second tube, and the tube is screwed into the sleeve until it stops.

As a rule, household pipes and heating systems are assembled in this way, the diameter of which does not exceed 6 inches. As for the welded joint, without proper experience, it is very difficult to do it yourself.

The installation process is as follows:

- Two connected parts should be tacked by electric welding at several points.

- After that, the axes of the two elements being joined are aligned.

- The final stage is the final welding - the joint should be boiled with a solid hermetic seam, which causes the greatest difficulty.

External and industrial pipelines are usually mounted in a welded way. The disadvantage of this installation is the difficulty of disassembling the system, in cases when it is necessary to replace a separate section of the pipeline. Here, perhaps, are all the main features of steel pipes.

Conclusion

Today there is a huge range of steel pipes. Therefore, they are used in a variety of industries, ranging from construction to mechanical engineering and furniture production. Accordingly, the choice of a type of pipes in each separate case depends on the tasks set before them.

From the video in this article, you can get more information on this topic.