Steel water and gas pipes - their characteristics and

Despite attempts to displace metal pipes with plastic counterparts, a water-gas pipe, called VGP, still remains a sought-after product on the construction market. Below we will look at its technical parameters with links to existing standards, as well as identify strengths and weaknesses.

There are three types - thin-walled, medium and thick-walled. Thanks to this, it is possible without any problems to choose an option that fits any project. It can be either galvanized or uncoated. The cross section is usually cylindrical, the presence of welds along the entire length is also characteristic.

Tip: when choosing these products should take into account that they are based on carbon steel.

Before getting ready VGP, carry out special processing of preparations (strips). This is necessary to improve the quality and durability of products. The main regulatory document for all manufacturers is GOST 3262 75 for a range of steel water and gas pipes.

Parameters and scope of systems

The name of the products corresponds - VGP is used in the construction of water supply systems and gas transmission lines. It should also be said that such products have universal capabilities, and, therefore, their scope of application is not limited to this (see also the article Welding of polypropylene pipes: 8 basic steps).

In industry, products are used whose length is in the range of 4-12 m.

In addition, when designing, you can vary such parameters as:

- material;

- diameter;

- presence of thread, its step.

Based on the strength of the products, they are classified as follows:

- lungs;

- ordinary;

- reinforced.

Depending on the conditions in which the products will be used, their appropriate strength should be selected. The main criterion is the thickness of the walls. For example, for:

| Hot water supply | Use GOST 3265 75 for galvanized thick-walled models. |

| Cold-water | The instruction allows to manage with average indicators. |

| Gas | It is enough to take low-profile options. This is due to the fact that the gas does not produce a negative impact when in contact with the inner surface of the product. |

There are galvanized or non-galvanized VGP products. The process of galvanizing is to increase the technical characteristics of the pipe by depositing a layer of zinc on their surface.

Tip: if there are risks of metal corrosion at places of use of VGP, such products are simply irreplaceable.

During the installation of plumbing systems with their own hands or hired labor must use galvanized stainless steel parts. It is worth noting that their use will increase the weight of the structure by about 3%, but this will significantly increase its operational life. The presence of galvanization will avoid the formation of rust and other negative processes affecting the integrity of the product.

With the final choice of mounting material is not worth saving. Low price corresponds to low quality, which in turn will significantly reduce the durability of the structure. Preference should be given to such details, which will correspond to the field of operation.

Regulatory Document

All building materials and products are manufactured according to certain standards.

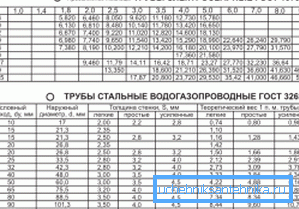

Consider the technical characteristics of AIV:

- steel grades - St1-2KP, St1- 1-2PS, St1-0,8PS;

- length is in the range of 4-12 m;

- diameters of steel water and gas pipes - from 10 to 80 mm;

- wall thickness - 2.5-4.5 mm.

If you read the regulatory document, for example, GOST 3263 75 per AIV, tolerances are the deviations from the thickness, however, with preservation of the mass of the product. Permitted mass deviations cannot exceed 8%.

For a batch of products, this figure is 7.5%, and for an individual product, no more than 10%. These parameters relate to deviations in mass of pipes.

In addition, there are indicators such as deviation from the curvature, which should be up to 2 mm per meter of product length. It should be noted that the indicator of conditional passage should be up to 2 mm for every 20 mm and not exceed the parameter 1.5 mm for all sections above 20 mm.

Positive and negative aspects of the use of AIV

Water and gas constructions are universal, which gives them a large number of advantages in their use:

- products are made of high quality steel, which corresponds to GOST 3262 91 on AIV;

- increase in pipe quality due to galvanization;

- the presence of reinforced welds;

- a wide range of pipe types (light, ordinary, reinforced);

- independent decision on the presence of threaded connections;

- using strict hydrovortex control ensures compliance with current standards;

- high quality products at a relatively low cost;

- universality of VGP;

- a wide range of products from different manufacturers and manufacturing methods (cold rolled, hot rolled, welded);

- large selection of components (pipe couplings, fittings, tees);

- high strength with low weight products.

VGP do not have serious drawbacks, the weld is considered to be a relatively weak point. The use of x-rays in the control of products will avoid all possible problems during marriage. The service life of such a system will directly depend on the place of use and the influence of negative factors (corrosion).

Electrowelded

These include the following types of pipes manufactured according to GOST 10704 91:

- round with straight seams O10-530 mm, O478-1420 mm, length - 2-12 m;

- profile products (in the form of an oval, rectangle or square) and pipes with a bent welded steel profile (square and rectangular sections).

The production of the latter includes the range of OO 10-100 mm, while the wall thickness is in the range of 1-5 mm. Pipes can be measured or unmeasured length, which varies from 1.5 to 9 m.

Closed welded steel pipes are made with sizes from 80 to 300 mm. Their length can be measured or unmeasured, as well as with multiple dimensions of 6-12 m.

Conclusion

The use of pipes in gas and water systems that comply with GOST allows for the creation of full-fledged communications in private and industrial construction. Due to their strength, you can not worry about their ability to withstand the pressure and the action of aggressive environment. The industry produces them not only with a round section, but also square (rectangular).

The video in this article will help you find additional material on this topic.