Stove for the stove - how to make a chimney

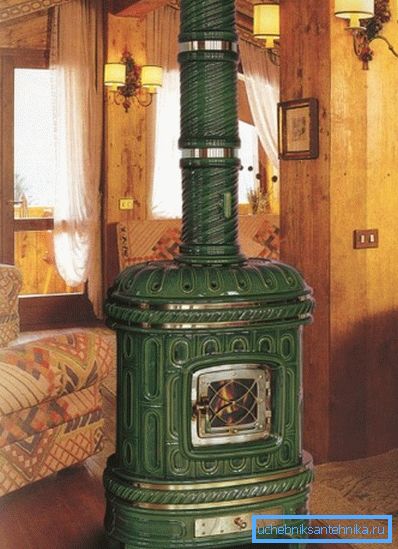

Despite the fact that the 21st century is already in the yard, and modern technologies surround us, stoves-stoves are not only relevant, but are also one of the most popular types of heating of country houses. This is primarily due to their compactness - such a furnace can be moved from place to place and melt anywhere in the house.

However, its efficiency and safety depend a lot on the chimney to which it is connected, so we will take a closer look at how to make a pipe for the stove itself for the stove to function as expected.

Chimney features

Before proceeding to the manufacture of the pipe, you should familiarize yourself with the features of the stove chimney, which is directly involved in the heating of the entire structure and, as a result, in the heating of the room (see also the article The VChGH pipes - features and application).

So, it consists of two parts:

- Heat exchange - located inside the furnace

- Gas Exhaust - is a pipe that connects to the exhaust pipe.

Now take a closer look at the device of each of these elements.

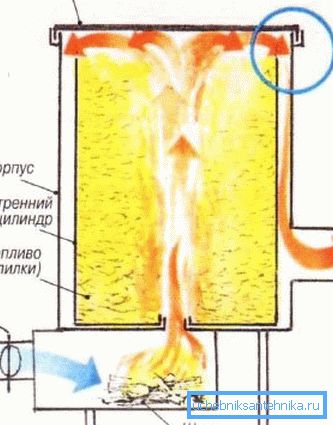

Heat exchange part

The most advanced and fireproof is the knee design of the heat exchanger. However, the location of the heat exchange elements in the body and their shape depend on the type of stove and the design of the chimney. All existing types of burzhuek can be divided into two types:

| Stretched horizontally | Exhaust gases enter the heat exchanger section (smoke chamber) through a side opening in the furnace wall, and only after that through the pipe they are led outside the room. This scheme allows to increase the efficiency of the furnace. |

| Vertically Stretched | Possess a more complex heat exchanger design. They, along with the knee, there are also spiral channels. This allows you to delay the smoke inside the structure and thereby extend the heating time. |

Gas outlet part

As for the gas exhaust pipe, which is most often understood as the word "chimney", it can be connected either after a valve capable of blocking the exit of gases or directly to the flue channel.

As a result of the foregoing, it can be concluded that the exiting gases enter the pipe, having already lost some of its heat. However, this does not mean that the chimney stays cold, which must be considered when choosing a material for it.

The order of manufacture and installation design

Materials

As mentioned above, the stove is a mobile oven, respectively, the pipe for the stove of the stove should also be light and, if possible, collapsible. Therefore, the option of a brick pipe will not be considered.

As an option, you can consider a chimney made of asbestos-cement pipes, however, it has some drawbacks:

- The temperature threshold of asbestos cement is 300 degrees Celsius;

- As a result of the roughness of the walls, soot quickly adheres to them.

- Fire hazard arises from the preceding paragraph, as soot will sooner or later catch fire, and asbestos cement cannot withstand such temperature.

- As a result of the reaction with hydrochloric acid, which is contained in the oxides, asbestos is gradually destroyed.

- The material has the property of absorbing condensate, which is subsequently transferred to the roof and walls. As a result, this leads to stains and unpleasant odors.

A much more optimal option is a chimney made from a metal pipe, which is not difficult to do on your own. The diameter of the pipe for the stove is selected in accordance with the diameter of the gas exhaust pipe.

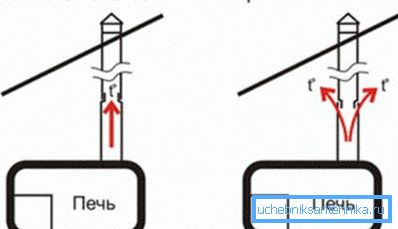

Note! The pipe should be put on the stove chimney and not inserted into it. Otherwise, smoke will enter the room.

The metal construction is quite easily done, in addition, the price of materials is quite affordable. However, it should be borne in mind that high-quality chimney should be made of alloy steel.

If the chimney is made for a stove located in the street, for example, in a gazebo or on a terrace, then for these purposes a flat pipe is used, which is necessary so that smoke does not roll around the stove and does not interfere with rest. If the stove is located in the house, the pipe is a knee system.

To perform such a chimney you will need the following materials:

- Elbow with a diameter of 100 mm and a length of 1200 mm;

- Two knees with a diameter of 160 mm and a length of 1200 mm;

- Three knees, intended for a joint, size 160 * 100 mm;

- Tee with a diameter of 160 mm with a plug;

- Fungus with a diameter of 200 mm.

In addition, depending on the room, you may need:

- Passing glass;

- Heat insulation;

- Anti-surge visor and some other materials.

Tip! It is possible to make not only the chimney from a metal pipe, but also the stove itself. Of course, a hand made stove made of a pipe stove will not look as aesthetically pleasing as the branded stoves, but for that it will do its job well.

Chimney assembly

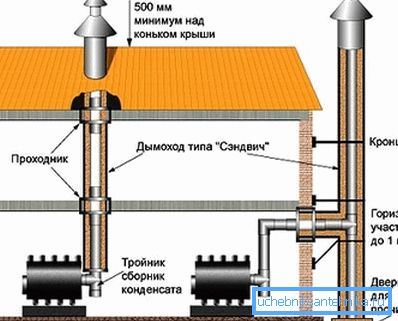

The output of the chimney on the street can be done in two ways:

- Through a window (window) or a hole in the wall - suitable for those cases when the furnace is installed temporarily.

- Through the attic and the roof - the best option, if the furnace is always in one place.

The installation instructions for the structure are as follows:

- The first step is to cut a hole of the desired diameter in the ceiling plate.

- At the edges of the hole it is necessary to remove the insulating material.

- Then a hole is inserted into the hole.

- Then through the glass through passage the knee is passed through and is joined to the external chimney, which leads the smoke through the roof to the street. Accordingly, in the roofing material also need to make a hole.

- After installing the outdoor chimney, it must be insulated with mineral wool and covered with bitumen.

- At the end of the work, a chimney pipe, located on the street, is put on a spark arrester or a fungus, which protects the system from small debris, living creatures and precipitation. At the same time, it also protects the roof from flying sparks.

Here, perhaps, all the main points of installation of the chimney system. When assembling it, it is necessary to observe the following rule - each upper knee should be put on the lower one, as shown in the diagram.

Chimney care

To ensure effective and efficient operation of the stove, it is necessary to monitor the state of the chimney, and to perform the following measures:

- Once a year it is necessary to inspect the pipe for cracks, rust and other defects that may cause smoke to enter the room.

- The pipe must be cleaned once a year. It is not difficult to do this at all - you just need to burn special chemical compounds in the furnace, after which the pipe will be cleaned.

By following these simple rules, you can significantly extend the life of the chimney.

Conclusion

Ensure a safe and reliable removal of smoke from the stove to the street can not even a professional. The most important thing is not to violate certain norms and requirements that we have considered above, as well as to select the appropriate material for the chimney (see also the article BNT Pipe - the subtleties of use).

Since the construction itself is quite simple, it is not difficult to assemble it.

From the video in this article, you can get more information on this topic.