Such different and so popular plastic pipes: the use of

With the beginning of the technical revolution, polymers increasingly occupy our living space and practically cannot do without them. For example, plastic fire extinguishing pipes (made of polypropylene) guard our safety. Also, polypropylene, polyvinyl chloride and polyethylene deliver water to our house, serve to drain sewage and transport coolant in heating systems. Of course, for the application of each of them has its own instructions, allowing you to navigate by operating pressure, temperature parameters and place of installation.

Polypropylene

General characteristics and nomenclature

Note. In technical documentation, different types of material have their own abbreviated marking. Thus, polypropylene has the abbreviation PPR (PPRC) or PP, polyvinyl chloride - PVC, and polyethylene - PE. In addition, PE pipes can be HDPE or LDPE - low or high pressure polyethylene, respectively.

At the moment, the use of plastic pipes very strongly pressed the position of the metal on the market. For domestic distribution of hot and cold water, as well as heating, polypropylene is most in demand, which has its own modifications.

When buying, you may find that PPR, PP-1, PP-2, PPB or PPRC are marked instead of PPR abbreviation on the tube. You should know that PPH and PP-1 are homopropylene, that is, the first generation of materials (it is worse). Now a random copolymer is produced, so if you see the characters PP-2, PPB or PPRC, you can be sure of the quality.

In addition, each pipe has the letters PN, which are tied to the numbers indicating the nominal pressure in bars at a water temperature of 20 ° C (all PPR characteristics are counted exactly from this temperature).

So, there are modifications PN10, PN16, PN20 and PN25. For cold water use PN10 and PN16, and for hot water and heating PN20 and PN25.

Here not only the wall thickness plays a role, but also the pipe reinforcement (their price is, of course, higher), which is carried out with aluminum foil or fiberglass.

- For cold water, the temperature of which never rises above 20? C, use the modification PPR PN10. It can also withstand briefly 45? C, but with prolonged heating from such a temperature, the pipe is simply deformed.

Working pressure is 1.0 MPa (10.2 kg / cm2). This modification is on sale with the external section from 20 mm to 110 mm, length - 4000 mm. Together with the diameter, the wall thickness also varies, which can vary from 2.3 mm to 10 mm.

- Similarly, for cold water, the temperature of which never rises above 20? C, use the modification PPR PN1. Unlike the previous model, this product can withstand 60? C, but with prolonged heating, deformation still occurs. Working pressure - 1.6 MPa (16.3 kg / cm2).

This modification is on sale with the external section from 20 mm to 110 mm, length - 4000 mm. Wall thickness - from 2.8 mm to 15 mm.

- For hot water and heating used reinforced modification PN20. Here, a working temperature of 80? C is admissible (for a short time - 110? C). Such a pipe is often called universal, as they make it all wiring (hot / cold water and heating).

Allowable pressure here is 2.0 MPa (20.4 kg / cm2), outer diameter from 20 mm to 110 mm, wall thickness 3.4 mm to 18.3 mm, respectively, length - 4000 mm.

- The reinforced modification PN25 is designed for high operating pressure in the system.. It constantly maintains 2.2 MPa (25.49 kg / cm2) and a nominal temperature of 95? C (short term up to 150? C). The outer diameter is from 20 mm to 110 mm (rarely 125 mm), the wall thickness is from 3.4 mm to 18.3 mm. Such pipes are most often used for centralized heating, where possible high pressure in the system (especially in high-rise buildings).

Note. Reinforcement pipes are usually laid in the middle part of the wall, but sometimes it does not. For example, in PN25 - there the foil may be closer to the surface and must be cleaned so that it does not interfere with the adhesion when welding with a fitting.

It is very inconvenient to do this with a knife, since it is necessary to pre-clean the top layer of polypropylene. For this purpose, there is a shaver, the cleaning process that you see in the photo.

Mounting accessories

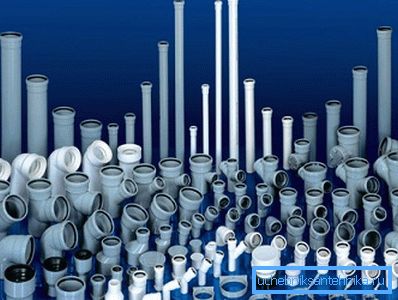

There are also accessories for plastic pipes that provide their installation and functionality - these are fittings, strokes, taps and, of course, an electric soldering iron with duralumin nozzles (possibly a Teflon coating) of different diameters.

So, among the fittings there are tees, quadrangles, couplings, plugs, angles of 32?, 45? and 90 ?, American and conventional threaded fittings. In addition to these parts, for optimal stacking when pipes cross over, there are short bypass nozzles, which are cut using couplings, and instead of metal, polypropylene ball valves, which have a service life not less than 50 years and above the pipes themselves.

Note. Some are interested in how to unscrew the eccentric from a plastic pipe, if its upper part has broken off and it is impossible to capture it with a key or pliers. This situation is difficult, so you have to either use a hex, or cut the splines with a file and unscrew with a small key.

Metalloplast

Basic Parameters

Pipes made of metal plastics are mainly used for distributing cold water and arranging the contour of warm water floors, although in some cases they are also used for external heating.

- The outer diameter here can be 16 mm, 20 mm, 26 mm, 32 mm, 40 mm and 63 mm, but the most popular section can be called 16-20 mm.

- Metal-based laminate has a very low thermal conductivity (1300 times less copper), it can be operated at an operating pressure of 10 bar and a nominal temperature of 0-95? C (for a short time - 110? C).

- For the most common cross section, the wall thickness is 2-2.25 mm, while at the same time, the aluminum foil layer will be 0.2-0.24 mm thick. At 1 linear meter with a diameter of 16 mm is 0.113 liters, and at 20 mm - 1,201 liters.

- The coefficient of expansion of metal plastics, regardless of the diameter of 0.2610-4 per? C, and thermal conductivity of 0.43 W / m * K.

Pipes and fittings

The metal-plastic pipe consists of three layers fixed together by glue: inside there is a layer of high-pressure polyethylene (LDPE), then aluminum foil goes, and outside a layer of low-pressure polyethylene (HDPE). If you purchase material for installing a floor heating system, then pay attention to the foil - this layer must be seamless or wrapped overlap

Tip! If you see a seam when cleaning the HDPE, then such a pipe for heating or hot water should not be taken. In addition, in order to save some manufacturers, they do not glue the foil to the PE - this is a sign of poor quality and such a metal laminate is suitable only for cold water.

As elsewhere, there are components for plastic pipes - these are various fittings for connection and wiring, samples of which you see in the images. But these compounds are the weak point.

If the operating life of metal-plastic pipes is 10-15 years, regardless of the humidity of the room, then brass connections do not always survive this period - they burst. It is especially dangerous to seal them with plaster or putty - absolutely all plumbers in such cases prefer polypropylene to metal laminate.

Polyvinyl chloride

For installation of sewage and air ducts (ventilation), non-pressure PVC pipes with a diameter of 32 mm, 50 mm and 100 mm are used, the length of which can be 250 mm, 350 mm, 500 mm, 750 mm, 1000 mm and 2000 mm.

For external sewage, a larger section is used - 150 mm, 200 mm, 250 mm and 300 mm, and in addition, casing pipes are made for sand and artesian wells, which ensure soil retention from collapses.

Docking of sewer pipes is carried out at the expense of fittings, which are produced in the following forms: coupling, angle (32?, 45 ?, 90?), Plugs, revisions, tees, quadrangles, PVC or rubber reductions (for switching from one diameter to another) . There are also complex fittings that may include several options. Nipple sleeves can be used to connect casing pipes or simply external and internal threads at their ends.

Note. It should be noted that repairing plastic pipes with their own hands is much easier to do than when working with metal. This is also one of the reasons for choosing plastic.

Conclusion

Despite the general acquaintance that you have already received after reading this material, plastic pipes may have some nuances in the parameters - this depends on the manufacturer. Therefore, when buying, always consult with the seller or carefully see the documentation. As a supplement to the above recommendations, we offer you a video in this article that will get you more closely acquainted with this topic.