The choice of corrugated pipes for exhaust

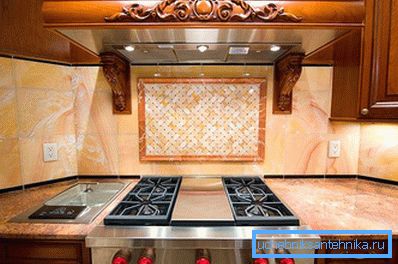

Whoever likes to cook, they know that when they stay at the stove for a long time due to the high temperature of air and fumes, their head starts to ache. 30–40 years ago, many people did not even hear about the hood exhaust, and at best installed an exhaust fan in a ventilation hole. But now everything is different. Many manufacturers of stoves have established the production of special extracts. In order to divert hot air from the stove, it is necessary to make a choice of corrugated pipes for exhaust.

Types of exhaust pipes

Since for drawing mainly channels of circular cross section are used, we will go through the materials from which they are made. Channels are:

- plastic;

- aluminum (semi-rigid);

- zinced with a polymeric covering.

Plastic channels create the least network resistance. But no matter what, high temperatures and plastic are incompatible things. Plus, plastic is flammable and fragile, especially after some period of operation.

Galvanized channels are used in rare cases where the channel must fall into the overall color of the kitchen. RAL catalog allows you to choose any color and shade of the polymer coating. Network resistance, like plastic - minimum. Strength and incombustibility bring these channels in plus.

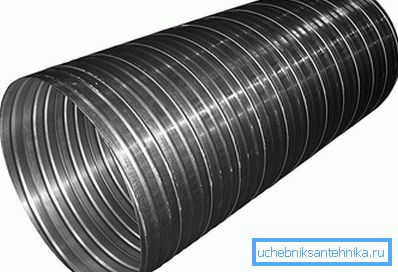

Corrugated aluminum pipe - the most popular of the round channels. But the duct must be semi-rigid. I have come across cases when an ordinary flexible duct was used as an exhaust duct. And this is an ordinary wire twisted into a spiral and covered with several layers of foil. Not only can such a channel be pierced through with a finger, it also reduces channel capacity almost by half.

Tip! Aluminum channel should be only semi-rigid. Yes, it cannot turn at any angle, like a flexible duct, but, on the other hand, if it is impossible to come to the exhaust channel with millimeter accuracy, it is permissible to use a short insert for connection, from a flexible duct.

Proper connection and operation of the hood

The golden rule of ventilation: if you want to remove the air from the room, for this you must supply air to the room. Reasonable, isn't it? But, despite the rationality, many of this rule is released from view. Then they are terribly surprised when the hood does not work. And the most deplorable outcome is obtained in the absence of air flow into the kitchen - a failure of the exhaust fan engine, which cannot work for a long time under this load, because it will have to not only push out the air, but also try to pull it into the room through the slots.

The regulatory documentation clearly states: the frequency of air exchange in the kitchen should be at least 3, i.e. if the volume of the kitchen is 35 m3, then for the hour in the room should come air: 35? 3 = 105 m3. Accordingly, the same amount of air must be removed.

Considering that the principle of ventilation in the kitchen is not forced, but natural, the installation of the hood over the stove makes it necessary to take certain measures:

- First, the channel must be closed by a wall grate. The grille should have a round hole in which the corrugated duct of the hood will be drawn. This hole should occupy no more than half of the living section of the lattice. Hot air, anyway, will still fall under the ceiling and it needs to go somewhere. What follows - it is strictly forbidden to block the channel from the exhaust, the entire cross section of the inlet of the exhaust shaft.

- Secondly, it is necessary to ensure a constant flow of air. To do this, when you turn on the hood, simply open the window or window. I repeat, if you secure all windows and doors, and turn on the hood, then be in trouble: the fan engine may burn. And given the very high performance hoods (up to 750 m3/ h) and the presence on many models of only one speed limit, the likelihood of disastrous consequences approaches 100%.

- Third, be serious about laying a corrugated channel. By itself, an aluminum semi-rigid duct cannot firmly clamp its cross section, it has such a construction. But when an inexperienced person takes over, he can do everything wrong: squeeze, squeeze and smash. Corrugation from the connecting pipe exhaust hood to the wall grille, it is desirable to lead a straight section. One or two turns are uncritical, but with zigzags to lead the duct is strictly prohibited.

Tip! Sometimes sellers recommend placing a check valve in front of the grate. In most cases, there is no point in this, since the valve is already installed in many models of hoods.

There is nothing difficult in connecting the hood from the stove to the ventilation duct. The main thing is not to allow annoying blunders, which we tried to disassemble in detail.

Video

Installation of the air duct for the kitchen hood: