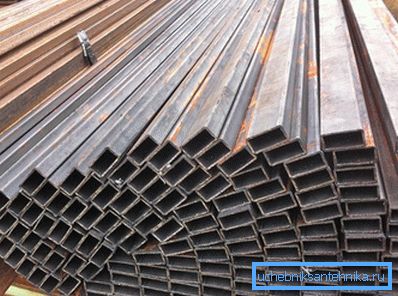

The frame of the house of the profile pipe

Profile pipes are a durable material suitable for creating a house frame. This material with the necessary tools you can bend, cut and install yourself. The frame of the house from the profile pipe is easily mounted even in the absence of professional construction skills.

Preparatory work

Having designed a house with a frame made of shaped pipes, it is necessary to choose the cross-section of pipes and their number using one of many construction calculators. It is necessary to consider all the structural elements that will be used when installing the frame of external walls, partitions between rooms, floors and roof, as well as floor beams and bottom trim. Fastening of building elements should be carried out using a welding machine.

Tip! When carrying out welding works, it must be remembered that their poor-quality performance can adversely affect the strength, reliability and integrity of the house itself. In addition, with the help of the level, it is necessary to exercise constant control over the verticality and horizontality of the mounted structural elements.

The metal structure, made of shaped pipe, is relatively light, so the foundation for the house can be block or pile. After the foundation has fully gained strength, it will be possible to proceed to the construction of the frame of the house.

The process of construction of the frame of the house from the profile pipe

The frame of the main structure of the profile pipes is mounted in several stages:

- The piping is made in the lower part, which is connected to the pile foundation with the help of welding.

- Fixing racks at the corners is made using the same welding. Racks are welded to the elements of the bottom trim.

- Fixing the racks in the vertical direction along the contour of the external walls is carried out in increments corresponding to the size of the material that will be used for wall cladding. The distance can be several centimeters less than the calculated one.

- The top trim device is carried out by fastening the racks to each other by welding.

- Strengthening of the welding structure from the profile pipe is made by strapping with spacer pipes. This step will increase the reliability of the design.

Tip! Bearing elements that will be subjected to significant loads, for example, vertical uprights or fragments of the bottom trim, are recommended to be made from pipe products with a thickness of 0.8 cm and a cross section of 10.0 × 10.0 cm. The cross-section of the spacer components can be 6.0 × 6, 0 cm

Further in the assembly process, the lag will be laid out of the same products, which in the near future will become the sub foundation of the subfloor. Lags are recorded using a welding machine. They are welded to the elements of the lower tier. In order for the floor surface not to vibrate when walking, the step between the lags should be approximately 0.5 m.

Then he arranges the frame of the ceiling of the house from a shaped pipe with his own hands between the floors. The structure of this frame structure includes side beams attached to the walls, overlapping profile pipes, to which the lathing will be attached to the bottom. The ceiling sheathing will be attached to the crate.

Tip! The distance between the ceiling beams should be such as to reliably withstand the load resulting from the redistribution of the weight of the upstream household items and people. The optimal step will be 0.5 m.

Further installation is carried out in the following sequence:

- Pipe profile elements with the help of a welding machine are fixed to the top piping of the structure parallel to the external walls of the structure.

- In the future, the turn comes to the installation of the system rafters. The roof can be made at first separately from the frame structure, or you can immediately build up the upper part of the house. If it is conceived to construct the roof from light roofing materials, it will be more practical and faster to weld the construction of the ceiling from the trusses below, and, lifting it to the top of the structure, to bond it with the same welding construction.

- If the roof is made of ordinary slate, metal tile or other heavier materials, then the construction of the rafters will need to be made of tubular elements of a significant cross section. This means that it will be very difficult to lift such a heavy roof. Conclusion - work on the device such a roof should be performed at height.

- Mauerlat, which is the basis of the roof, is also made of a channel of significant cross section, because the supporting structure of the roof will be welded to it. Profile pipes are used for the remaining elements of the roof - skates, girders, rafters and other parts.

Tip! Houses, which are based on a frame construction of shaped tubes, have many cold bridges. Therefore, special attention should be paid to the thorough weatherization of the house. In addition to thermal insulation of the frame stand, it can be treated with Penoizol.

The house, built on the basis of the construction of shaped tubes, is an original structure, which is not often constructed.