The main types of water pipes: understand the technical

The organization of any water supply system in a private house or apartment always begins with the selection of suitable pipes for the future water supply system. Next, work with fittings is carried out, gluing and welding processes are performed, the water supply itself is laid and installed. Different types of water pipes are suitable for different purposes, so you need to know their basic technical characteristics and capabilities that will help you make the right choice.

It is better to select materials for the plumbing system that will be easy to handle on your own, that is, do all the necessary pipework with your own hands.

Types of pipes used for indoor and outdoor water supply

The main type of pipes are metal water pipes, and the installation features of these elements directly depend on the properties of the materials used. These pipes are universally installed in residential apartments, they have their advantages and a number of drawbacks, which everyone is well aware of.

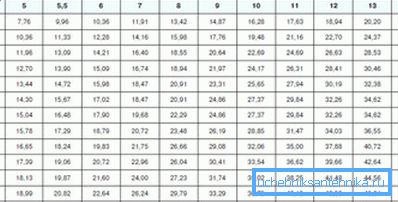

If you have decided to change your system and begin to select components, then you will need a special table of dimensions of water pipes. It is quite simple to use it, the main thing is that now you will not get confused in size.

Steel tubes

Pipes made of steel - it is durable, cheap, and most importantly reliable version of plumbing. Almost in all city apartments almost all risers are made of this material.

All heating radiators are mounted from steel pipes. The main disadvantage of this material is its susceptibility to corrosion. To avoid damage, they are specially applied zinc coating. For maximum protection, zinc is applied both inside and out.

The service life of water pipes made of steel reaches several decades, namely 30-40 years. Nozzles have a high level of thermal conductivity, so cold water pipes often “sweat”.

There are three main ways to connect these elements of the water supply:

- clutch,

- welded,

- with special press fittings.

If all elements are galvanized, then only the last option can be used, as welding can severely damage the anti-corrosion layer.

Cast iron pipes

Iron pipes, unlike steel, are able to resist corrosion, but it is worth understanding that this material is quite heavy (this is its main drawback). Cast iron pipes usually have thick walls.

These pipes can be safely used in sewage systems and water supply. The service life of pipes made of cast iron from 80 to 100 years. Sealing sockets and gaskets are used as a joint of such elements.

Depending on the mass, the following types of water pipes are distinguished:

- Average;

- Heavy;

- Very heavy.

A special anticorrosive layer - silicate-enamel is applied on these pipes. The pipes are high-strength, they are resistant to temperature extremes, in addition, they have a low coefficient of expansion.

Copper pipes

The diameters of copper water pipes can be different; each diameter is used for specific purposes. For quite a long time, the pipes made of this material have won the title of elite for themselves. Under the most adverse conditions, the life of the sewer system will be 70 years.

Copper practically does not deteriorate, that is, the elements of the water supply do not change their working qualities. Separately, it is worth noting the bactericidal properties of the metal, it is very important, because clean drinking water flows in the pipes.

If you have copper pipes installed in your house, then there is no need to use rigid filters for water pipes. Copper is not exposed to ultraviolet rays, it is not afraid of changes in atmospheric pressure.

Note! Temperature range of work - from minus 200 to plus 500 degrees Celsius. Copper is not subject to corrosion.

Copper pipes are ideal for use as the basis for the heating system, as well as hot and cold water. The installation of these nozzles is simple, the elements are quite flexible, easy to solder, they are perfectly sawed.

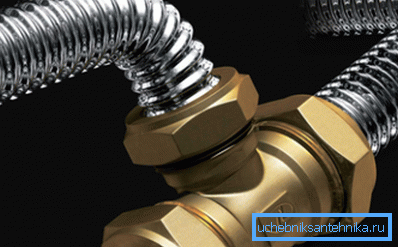

One of the main ways to connect them is high-temperature soldering. Solder for these purposes is selected silver-bronze. The most convenient method of installation involves the use of pipe fittings. The only disadvantage of these connections is the high price that can scare away many potential buyers.

In order to correctly design and arrange a water supply system, it is necessary to very carefully examine the various sizes of water metal pipes, comparing their performance, technical, and aesthetic characteristics.

Tip! The choice of the type of a particular pipe depends on its purpose: it is planned to implement an internal water supply system, or it is necessary to implement the installation of any external communication.

There are a lot of options for solving this issue, so the question should be worked out in detail, this will allow you to avoid a number of unnecessary mistakes and unnecessary cash costs.

Main technical characteristics of water pipes

Water supply and sanitation networks are divided into two large groups:

- Outdoor networks;

- Internal type networks.

Both options involve the use of pressure pipes, which are designed to supply both hot and cold water through them under appropriate pressure.

The main parameters of the water pipes include the following parameters:

- High corrosion resistance;

- Chemical resistance;

- Long service life;

- Resistance to sudden temperature changes;

- High bandwidth.

Plumbing elements have a special classification and materials.

It is worth noting the following:

- Metallic (discussed above). In this view, a separate item is a corrugated plumbing pipe;

- Polymer;

- Metal-plastic (in this embodiment, polymeric materials are combined with metal elements).

Sizes of metal elements of a water supply system

The dimensions of water pipes in mm are considered traditional for us. But in practice, most sizes are indicated in inches. So, for example, the half-inch metal pipes have an internal diameter that is approximately equal to 12.7 mm.

When installing any type of pipeline, it is not only the internal diameter that is important, where the external diameter is more important. This is due to the fact that on the outer wall it may be necessary to cut pipe threads, which is simply necessary for connecting sections of the water supply system.

The outer diameter directly depends on the inner diameter and wall thickness. It is equal to the sum D int. plus double the wall thickness product.

At the moment there is a special system of pipe threads, which are cut on the outer surface of the wall of the nozzle. For pipe threads, the internal diameter is taken to be D inside. It is on its outer side that the thread is cut.

For pipe threads, after the diameter value it is necessary to separately indicate the designation of “pipes”.

Instructions for reading: 1/2? pipes - this means that D int. equals 12.7 mm, and external - 20.4 - 20.7 mm.

The following types of steel pipes are used in all types of plumbing systems:

- Welded water-gas pipes, the diameter of which is in the range from 6 to 150 mm;

- Oil-water pipes, seamless, wall thickness from 4 to 9 mm. These connections are able to withstand pressure up to 16 technical atmospheres;

- Branch pipes with a special spiral seam, which, as a rule, are specially made thin-walled.

The ratio of the diameter and wall thickness of steel pipes are divided into three main types:

- ordinary,

- lungs,

- reinforced.

If the pipeline does not have any special requirements for resistance to peak values of working pressure, then you can stop your choice on an ordinary type, because these nozzles are lightweight and easily processed.

Important: reinforced elements are poorly joined by gas welding, therefore they require the use of non-standard tools for threading.

Conclusion

Now you can independently answer the question: which water pipes are better and make the right choice, on which the reliability of the entire system will depend on in the future.

In the presented video in this article you will find additional information on this topic.