The need for an additional pipeline: how to install pipe

Sometimes it is necessary to connect additional lines or valves, fittings to an existing pipeline, as well as to perform emergency repairs. In this case, the so-called sidebar is performed.

Depending on what kind of engineering network you are connecting to, the ways of the tie-in device are different, which we will discuss in this article.

Insertion into existing networks

Decisive in choosing the method of connection to the already existing engineering networks is also the material from which the pipeline is made. Of course, the simplest and most effective way is to weld the branch pipe into the main line, but for this you need to turn off the water supply, for which you will have to turn to emergency services.

Water pipes

Often the question is about the performance of work without disconnecting end users, so classical welding and other techniques are not effective here. Consider how to crash into a water pipe under pressure, that is - without turning off the water in the network.

When it is necessary to perform work, as experts say "under water":

- Such situations may occur when the locking devices (valves) fail, which interrupt the water supply to the repaired or reconstructed section of the pipeline.

- When connecting the water supply of a private house in the central highway.

Attention! Inset of private water lines into the central water supply is carried out only after coordination with the municipal water supply system. In the case of unauthorized tampers, you may be subject to heavy fines.

Outdoor networks

The connection is made in the nearest water well in one of the possible ways for a specific situation:

- Provided the water supply is shut off:

- With the use of welding.

- With the help of connecting fittings on the central conduit mounted during its installation.

- Under pressure - insert into the pipe without welding with a clamp:

- Classical - from two metal strips with coupling elements along the edges.

- Rubber casing.

- Metal saddles.

- Flange.

Note! Any of these clamps can be used in work with cast-iron, steel and asbestos-cement pipes. The exception is PVC pipes, for them there are special devices.

Let's see how in practice is carried out inset into the water pipe. The work is simple, it is quite accessible to do-it-yourself, but subject to the observance of safety precautions and without disturbing the sequence of operations.

Here is a step-by-step instruction for coupling coupling for the following tie-in:

- The section of the central water supply, scheduled for the frame, is freed from the insulating layer and carefully cleaned. The diameter of the outlet is of course much smaller than the main pipe.

- A clamp with a flange and a branch pipe is installed on the line. A valve is attached to the flange, and special drilling equipment is attached to it.

- When the valve is open, the necessary size of the cutter is passed through it and the gland of the blind flange (sharpened products allow making holes much easier and faster). At the end of drilling, the cutter is immediately removed.

- Then the latch is locked and you can dismantle the rig for drilling.

- When the inset into the pipe under pressure is finished, the insulation of the main pipe should be restored.

Internal water supply

When the device is diverted on the internal water supply system, a tube is inserted into the pipe at a right angle by installing a tee. For similar work on steel pipelines used welding work.

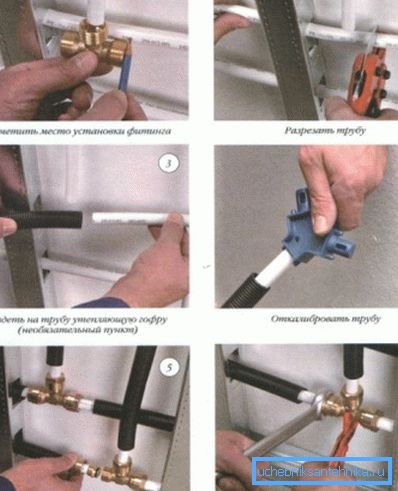

But now they are fading into the background of the thoroughly trampled on plastic counterparts. Insertion into the polypropylene pipe is carried out by extracting the required length of pipe from the conduit by simple cutting out.

The removed area must strictly comply with the parameters of the tee, which will take its place. This procedure may be hampered by the proximity of the pipeline to the walls of the building.

How to crash into a polypropylene pipe in a simpler way? For this, a method has been devised that does not require cutting the existing water supply system.

For this you need:

- Take a piece of pipe of the same diameter as the water supply pipe with a branch pipe for a drain to another line.

- The pipe is cut along and, like the second skin, worn on the section of the existing conduit in the right place after drilling.

Note! For simpler cutting, you should use a vice in which a round product is easily clamped, it will not slip out of your hands.

- Sealing the connection of the nozzle and the conduit is achieved with a non-hardening sealant.

- The pad is clamped on both sides of the branch pipe with hose clamps prior to squeezing the sealant out from under it.

- Next, an additional water supply line is connected to the nozzle.

Specialists call such a mortise pipe clamp for a curvilinear flange.

Sewage

To date, in terms of repair in places or partial reconstruction, an insert is used in a sewage pipe made of cast iron with the help of modern plastic products.

Note! High-quality inset in the cast-iron sewage pipe of individual parts will extend the life of a still quite suitable drainage system, without costly complete replacement of the drainage system. However, you should first contact the specialists who have to evaluate the area allocated for the restoration, in some cases, replacement by insertion does not eliminate the problem in the sewer system, but only aggravates the situation.

The algorithm for making reliable and durable compounds of cast iron-plastic:

- Before crashing into the sewer pipe, it is necessary to inspect and dismantle old pipes from the riser with great care.

- If it is impossible to do it carefully with the help of ordinary plumbing tools (adjustable spanner, gas wrench), use a grinder (angular grinding machine) and simply cut the pipes in the right place.

- Upon completion of the dismantling work, we perform measurements and selection of the required fittings.

- If the existing drainage system is connected to the socket, then you can use a special rubber adapter from cast iron to plastic.

Tip! To buy any plastic parts of the sewage system in a wide range is now possible in every hardware store. The price of such products is low and quite affordable for absolutely all buyers.

- The old bell is carefully cleared of perennial layers. The rubber adapter is smeared with glue and sealant and put into a cast-iron socket, then a plastic pipe is inserted. It is necessary to wait until the sealant hardens and only then use and check the efficiency of the sewage system.

Insertion into the waste pipe of the waste system is carried out for the installation of a special valve for ventilation and pressure control in the sewage system. As you understand, it improves system performance and reduces the number of blockages that are formed.

Conclusion

In general, the process described above requires careful preparation, as some pipeline systems are in a very seedy condition, any disturbance will lead to failure. Therefore, without a specialist inspecting the site where you are going to work, we do not recommend you to do anything (see also the article Cold-deformed pipes: standards and production technology).

This can end badly not only for you, but also for innocent neighbors who will be left without water. In the presented video in this article you will find additional information on this topic.