Threading the pipe: 2 ways to create a reliable connection

Recently, most pipelines, regardless of their size and functionality, are made of plastic or other modern materials. But sometimes there is a need for repair or installation of metal products. Therefore, instructions on how to cut pipe threads to connect these or other parts are unlikely to be superfluous for you.

Varieties of threaded connections

There are many different types of carving. There are metric and inch, right and left, as well as various forms of the profile. But in most cases you will only work with triangular.

Let us consider other differences.

Inch is characterized by the following:

- all markings on the cutting tool are in inches;

- in profile it looks like an isosceles triangle, whose apex angle is 55 degrees;

- the pitch between the coils is larger, because the connection is more durable.

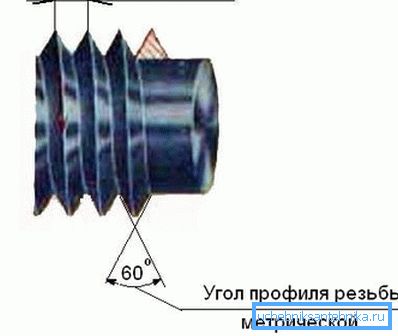

Metric features:

- measurements and markings are made in millimeters;

- each turn has the form of an equilateral triangle;

- the distance between adjacent turns is smaller than that of an inch.

The first is used to connect water and drainage systems, and metric - in all other cases.

As for the other classification criteria, everything is obvious here:

- with right-hand threading, the nut is screwed clockwise;

- in case of left-side cutting, it is necessary to rotate the nut counterclockwise to fix it.

Method 1. Using an electric tool

Modern industry produces many power tools that facilitate and accelerate the work of both professional builders and those who love to do something with their own hands.

Therefore, it is not surprising that in construction stores a machine is sold for cutting threads on pipes, which allows you to make a high-quality and reliable connection, especially on small workpieces that are hard to fix when cutting manually.

This device is equipped with a powerful electric motor with a gearbox that rotates the cutting tool, which are the dies (Lerka) of different diameters. You just need to press the starting lever and wait for the process to finish.

But such a device for cutting threads on pipes has a drawback. When processing a large number of blanks die can overheat and break. This will not happen if you take breaks during cutting, but then the question arises whether the device should be purchased, the price of which is quite high.

It should be noted a few important nuances:

- using power tools it is very difficult to cut long threads in several places on workpieces whose diameter is greater than 1 inch;

- machine for cutting threads on the pipes does not allow to work if the part is installed too close to the wall surface.

Tip! It is advisable to acquire an electric screwdriver only if you are professionally engaged in the installation and repair of water supply systems, including metal pipes. When it is necessary to process parts only from time to time, it is better to buy a manual set for cutting threads on pipes, the capabilities of which will be quite enough for most applications.

Method 2. Manual threading

Thread Assignment and Tools Used

Before you go directly to the process of work, you should decide why you need a thread.

The fact is that only with the help of this type of joints are joined:

- plastic parts with metal;

- valves and other similar parts;

- plumbing fixtures.

Currently used for cutting:

- special die (lerka);

- screw die (or as it is called the club for cutting pipe threads).

With the help of these tools it is possible to carry out the joining of products for any purpose and diameter.

Tip! If you do not have experience in plumbing, it is advisable to use a screw die that has an axial guide, which facilitates the process. The use of dies requires some skills. Otherwise, there is a danger of ruining both the tool and the pipe.

Preparatory stage

Having bought the tool chosen by you for cutting threads on pipes, we start performance of work.

First, prepare the stock properly:

- the pipe is cleaned from traces of corrosion, remnants of the existing coating, dirt and dust until a characteristic metallic luster appears;

- from the end of the workpiece with the help of a file chamfer is removed;

- the cutting place is well lubricated to facilitate the work of the cutting tool.

If you use a plate, it is recommended to practice before starting work on a section of the old pipeline. Incorrectly made threaded connection will not allow to connect the necessary details.

In addition, it is not recommended to save when buying a tool. Substandard dies or pipe plug may damage the entire pipeline.

Thread cutting with die

In the case when you for the manufacture of compounds used dies, the procedure will be as follows:

- The pipe is clamped in a vice or fixed in another appropriate way. It is necessary that during operation the workpiece is completely stationary and securely fastened.

- The die of the required diameter is installed in a special holder and fixed there with the help of appropriate screws.

- A lubricant is applied to the pipe and die, which facilitates the work and protects the instruments from damage.

- Then you should carefully place the tool on the end of the workpiece and, rotating it clockwise, cut the first turn.

- Remember that the plate should be located strictly perpendicular to the workpiece.

- Having made the connection of the desired length, unscrew the tool and walk it over the connection again.

Work with the screw die

This device allows you to easily cut the thread, even inexperienced masters. It represents the same plate, but additionally equipped with a guide device and a ratchet. Most often sold in a set with leerk different sizes.

The work is as follows:

- The screw die of the desired size is installed in the ratchet and fixed.

- At the end of the pipe and the tool is applied lubricant.

- The guide is put on the end of the pipe. This ensures that the cutting tool is strictly perpendicular.

- For cutting should rotate the ratchet.

- In the process, you need to additionally lubricate the desired area of the workpiece.

The reasons for the appearance of defective thread

If you do not comply with the requirements listed above, the thread may turn out to be defective, which will not allow high-quality and tightly attach the valves or fittings for sewer pipes.

The most common causes of marriage are:

- incorrectly selected tools - the diameter of the pipe and the plate, the connection step or its appearance does not match each other;

- poor quality dies or diets - if the cutting edge is damaged or blunt, to make a quality connection will not work;

- insufficient amount of lubricant;

- use dies without appropriate experience in the work.

Conclusion

The threaded connection, despite the difficulties in its manufacture, is one of the most reliable and durable. More details about the pipeline installation process can be found in the video in this article.