Trenchless pipe laying: features of this modern and

Trenchless pipe laying is a common name for all similar works performed by the closed method. These technologies are more promising and preferable than open styling methods, since much more economical.

Features of closed pipe laying methods

The following technologies belong to the closed types of laying.

- HDD - horizontal directional drilling.

- Micro tunneling.

- Squeezing metal cases.

- Drilling with auger method.

- Puncture method.

We will talk about the first of them in more detail.

HDD method

This method is the most universal and suitable for the closed laying of various engineering networks. It can be used to install polyethylene, steel, cast iron pipelines with a cross section of 63/1000 mm, at depths of up to 25 m (find out here how the cable is laid independently in pipes of various types).

Note! The length of such underground sections can reach 1.2 km. It is dependent on the pipes that need to be dragged. To implement the work of a particular method, as a rule, is selected at the construction site.

It is mandatory to make working drawings, because Most of the closed technologies are interchangeable.

Trenchless pipe laying is suitable for transporting gases and various liquids.

With her help they pull:

- electrical cables;

- water pipes;

- gas pipeline;

- pipeline;

- sewage system;

- communication cables and other networks.

Applied machinery and equipment

The main tool for the implementation of the method of HDD are drilling rigs.

As an additional technique are used:

- pipeline builders;

- location systems;

- current generators;

- mixing and mortar nodes;

- welders;

- auto-manipulators for delivery of drilling equipment;

- motor pumps, etc.

Advantages of trenchless ways

- The volume of earthworks is significantly reduced.

- The cost of construction can be reduced to 30%. Including, thanks to the involvement of a smaller number of workers and special equipment.

- The construction period can be reduced by 15/20 times.

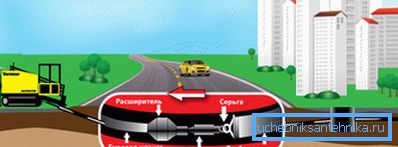

- The landscape, including landscaping of the site, remains unchanged.

- The road surface is preserved.

- Possibility of laying pipes under subway lines and power lines, shallow reservoirs, oil and gas pipelines, in loose soil and rock formations. You can drill wells and under environmental zones, land construction which is prohibited.

- The use of installations for HDD greatly simplifies the procedure and reduces the time for obtaining permits and conciliation documentation for the implementation of works.

- Using the method eliminates the blocking of streets or blocking traffic.

Technology works

Laying pipelines using HDD involves the following stages of work.

- Geodetic study of the site and the determination of the properties of the soil. As required in the problem areas drilled holes.

- Design work involves the calculation of the drilling trajectory, the preparation of the necessary documentation, its coordination in the relevant instances.

- Direct preparation for work: excavation of the starting and preparatory pits, delivery of drilling equipment to the construction site, bringing it into working condition.

- Drilling a pilot channel.

- Increase its diameter.

- Pipe laying

- Completion of construction work.

Drilling preparation

- At this stage, all data relating to the characteristics of the soil at the construction site are collected and studied. The composition of the soil, its properties, the presence and depth of subsurface water and underground utilities are taken into account.

- In order to select the optimally suitable equipment and technology, soil sensing is carried out.

- After the design, work should be coordinated and permits should be obtained for laying the pipeline in this section.

Test well

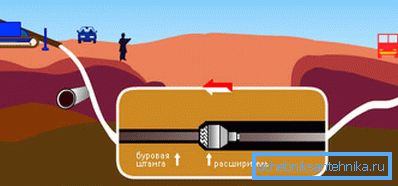

The instruction warns that the laying of the network should begin with the creation of a pilot well.

- For this purpose, special drilling equipment and tools are used to equip horizontal wells. The machine is equipped with a drilling head with a radiator.

- It is combined with the drill rod. Changes its direction and position do it yourself operator of the machine. The boom is a steel pipe, having a length of up to 3 m and a cross section of 60/80 mm.

- As the head goes deep into the rock, the rods are screwed in sequentially into each other.. So until the design length of the well is reached.

Note! The main task of this stage of work is to drill a well precisely along the path defined by the project. Deviations from it are unacceptable.

- Such drilling is also called directional.. Its course can be easily and easily controlled. The work process is monitored due to the sensor mounted in the drill head, which sends signals to a special locator.

- If data on the bar deviation from the design course appear on the monitor, the operator returns it to the desired trajectory with several movements.

- Since when using HDD, layers of soil and rocks are destroyed, to prevent collapses, collapse of the well and possible equipment failure, the walls of the channel are strengthened. For this purpose, a special drilling mud (bentonite) is used.

Channel extension

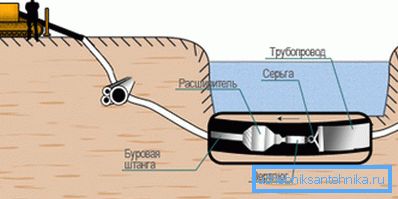

- Next, the pilot well is expanded to the desired size. For this, extenders are used.

- The tool is pulled from the output end of the channel to its beginning. During the operation, it rotates around its axis and cuts the rock, thereby increasing the diameter of the well.

- In order to be able to stretch the pipes through the well without problems, the size of the channel must be 35/50 percent greater than their diameter.

- If it is intended to install a large-diameter pipeline, the well is expanded, consistently pulling through it 2/3 of the extender. The cross section of each of them is greater than the previous one. In some cases, a calibrator is used for this.

Pipeline laying

- Drilling rigs are used not only to create horizontal wells, but also to lay the pipeline in the way of pulling.

- From the back of the channel towards the machine, the expansion tool is pulled again. At this stage, the pipe lash is fixed on it, as well as the grip for pulling it.

- Moving in the direction of the drilling unit, the expander pulls the pipe along the channel.

- The process is monitored by an operator. It keeps track of the number of drill rods selected from the well. This makes it possible to obtain information about the pipe pulling through the channel.

The final stage

- When the closed pipe-laying is completed, the experts check the quality of the created network, compare the result with the project documentation and deliver the object to the customer.

- Transmits the finished pipeline working engineering group. Experts give the customer all the necessary documentation. It guarantees the maintenance of the facility.

Note! Technical documents on the installed pipeline must necessarily include a detailed plan of the underground engineering network, with its reference to the terrain. It is needed, including when trenchless pipe replacement is carried out.

Conclusion

Trenchless pipe laying by HDD method is a modern and high-tech way. It allows you to mount engineering networks very quickly, while spending relatively little financial resources (see also the article Laying of sewage pipes in the house: a step-by-step guide on the arrangement of the sewage system).

The video in this article will give you the opportunity to read more information.