Tubing: destination and types of products

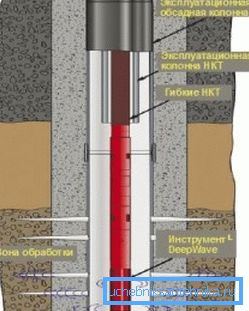

This type of pipe is actively used in the development of gas and oil fields. They also carry liquid and gaseous substances for various purposes. Tripping and repair work is effective if tubing tubing is used.

Distinctive features of products

Since tubing is often used in extremely harsh conditions, their technical characteristics are required to ensure the productive operation of the equipment.

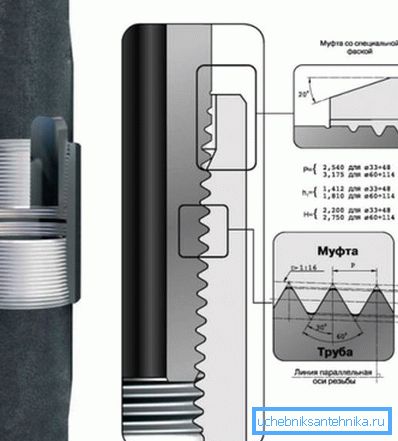

- The pipe must be completely sealed.. Also tightness and reliability are required from the joints of the fragments. Threaded couplings are considered the most practical for this case.

- It is worth noting the increased requirements for durability with constant mechanical effects.

- The instruction provides for an increased level of terrain. The pipe often faces intense distortions in the borehole.

- Since the products are in direct contact with aggressive media, the ideal resistance to corrosion and erosion is taken into account..

- Pipes are suitable for repair. That is, the possibility of restoring the damaged area, not replacing it completely.

- Product profile has no seams. The surface without joints allows to increase the efficiency of oil, sulfur, gas and other production without technological failures.

- Tangible impacts, perpendicular to the axis of static loads, deformation of the product is not terrible.

Pipe types

Depending on the specific purpose, you can choose tubing with certain characteristics.

- Reinforced tightness.

- Reliable protection against low temperatures.

- Polymer sealing unit.

- Resistance to high temperature.

- Increased corrosion resistance.

Note! The diameter of the pipes, as well as their purpose, can vary significantly. So, manufacturers offer material with a diameter of 60 mm to 114 mm.

Suggested types

- With smooth ends. The pipes and couplings themselves are made of high-grade steel with strength markings denoted by the letters K, E, L, M.

- With the ends landed outside. For their manufacture is steel grades D, K, E, L, M. To eliminate corrosion and teasers, as well as to ensure increased tightness, pipe threads are coated with special lubricant.

- Bezmuftovye, with the landing outside. The technology guarantees the preservation of tightness even at a pressure of 50 MPa. Below the trapezoidal thread of a smaller diameter are tapered seals.

- The clutch pipes also have trapezoidal threads and, according to GOST, withstand the same pressure (up to 50 MPa) as well as clutchless ones.

- Pipes NKT from alloys with aluminum. They are distinguished by the absence of hydrogen sulfide corrosion, so the use of inhibitors is not necessary. With a minimum weight, this type is higher in strength than steel equivalents by 2.5 times.

- Products with specialized coatings. It is recommended to use them in areas with a high content of chemically active substances. The composition of the coating does not interact with the gypsum salts, paraffin, protects against corrosive processes. Liquid-coated pipes are particularly popular.

- For producing, injection, gas-lift and utilization wells, manufacturers offer fiberglass pipes.

Operational features

To preserve the original qualities of the material, it is necessary to strictly follow the rules of transportation and storage of pipes.

- Delivery must be made using special equipment. It is strictly forbidden to drag the pipes with your own hands, without a crane and a pipe truck.

- Do not allow the material to sag, be dropped from the carrier to the ground. Unloading is made only by crane, laying on a flat, prepared surface.

- Excludes storage directly on the open ground. Under stacks enclose bars, the warehouse equip a temporary roof.

- Screw the safety ring onto each pipe before storing it.

- The longer the product remains in stock, the more thorough the inspection is carried out before use.

- To identify possible rejects, a special template is driven through the pipes. Its diameter is 2-3 mm less than the internal diameter of the pipes, and the length is from half a meter to a meter.

Note! For any manipulation (loading and unloading, inspection, maintenance) work is carried out with several assistants. There is a high probability of damage to the material when kantovke alone.

- Before screwing the pipes, the threads must be cleaned of impurities with a metal brush. Nipples and couplings for pipes should be treated with a special lubricant.

- It is strictly forbidden to use a sledgehammer to facilitate unscrewing the pipe.

- The sections lifted from the well are placed only on previously prepared walkways lined with wooden bars.

Complete set of finished products

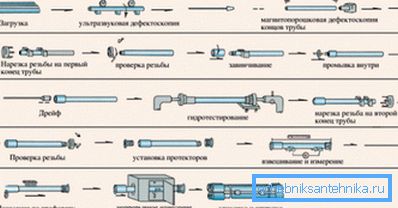

Manufactured at the factory NKT, before sale, are thoroughly tested for compliance with GOST standards.

Consumer is offered a quality product that meets all standards.

- There is a strictly fixed price for pipes. It is not necessary to purchase material from small firms with a dubious reputation at an unreasonably high cost.

- If desired, the external surfaces of pipes can be coated with a special anti-corrosion layer.

- Pipes are supplied with markings, stamps and painting in accordance with the requirements of regulatory and technical documentation.

- The kit includes add-ons in the form of protective elements for threaded connections. Couplings and thread are covered with special grease.

- If necessary, you can order packaging in the form of paper bags with crates of reinforced polyethylene and steel tapes.

Conclusion

By purchasing finished products, consumers can be confident in their quality. Further successful operation depends on strict adherence to technical requirements for pipes.

Attached video in this article will add a list of useful information.