Types of fittings

What are fittings? This is the name of the components of any pipeline that are necessary to connect its various parts with each other.

Actually, fittings are necessary for connecting pipes and are used to change the direction of the pipeline, also, if necessary, for branching or when it is necessary to connect two pipes of different diameters.

Speaking of pipe fittings, it is worth mentioning which materials are used for pipes in various communications:

- metal, in particular, stainless steel;

- plastic;

- The composition of these two materials is metal-plastic.

Tip! When purchasing fittings, you need to consider that the material from which they are made must be identical to the material of the pipes.

What are the fittings

The differences in fittings can be determined by several parameters. For example, their size and shape may depend on the following indicators:

- pipe diameter

- pipe material

- where they will be applied.

Now a little more. The diameter of the pipes also affects the diameter (internal or external) of the fittings; therefore, when buying fittings, you need to know in advance the size of the pipes you have to work with. Otherwise, you will not be able to answer the question of the seller, what diameter fittings are needed. Speaking of diameter, it is understood that both fittings with identical diameters of outlets, when the size of the pipes are the same, and adapters can be used if it is necessary to connect a larger pipe with a smaller one.

When it comes to what material should be used, you need to take into account some points. For example, if threaded types are used, the connection must be sealed with flax, FUM tape or something similar for greater tightness. When welding, tightness is determined by how carefully the seam is made.

Fittings for flanges are sealed exclusively with rubber gaskets, and when using crimp - using sealing rings, pre-lubricated with sealant. Mixed fittings also exist (a combination where one side is welded to the pipe and the other is threaded).

Crimp fittings are most commonly used, because it is thanks to them that the reliable tightness is best ensured without welding and threading. They are easy to install, they are easily removed, and the process can be carried out more than once.

Scope of application

Depending on the scope of use, the fittings are divided into:

- taps and angles due to which the angle direction changes in the range of 45-120 ?;

- distributing elements - crosses, tees and collectors - for the device T-shaped and X-shaped connections;

- plugs that are placed at the end of the pipe, so that it does not need to brew;

- fittings to connect the pipe with flexible hoses.

Types of compounds

Metal-plastic pipes usually have two connection options, namely: collet and press-fitting methods. In both cases, plastic soldering is required.

For metal pipes, fittings are used when:

- there is a system with hot and cold water supply;

- there is a heating system;

- you need to join the faucets, cistern in the toilet and so on.

Fittings are also used in the chemical industry, in the oil and gas industry, as well as in the field of semiconductors. There they are popular because of their ability to create a system that is completely airtight throughout its length.

The main advantage of fittings for plastic pipes is that they do not need welding and can be easily and quickly installed. Do I need to buy special tools to work with them? No, neither is it required to have any special construction or plumbing skills. Thanks to their use, the labor intensity of the entire work is significantly reduced, including the installation of heating pipes and plumbing in a house or apartment. They can also be used if there is a need to create a pipeline from parts made of different materials or of different diameter.

The fitting is indispensable when installing pipes on the basis of metal-plastic, because there are situations when the system urgently needs to be dismantled or removed from it some parts for their replacement or maintenance. Then, thanks to fittings, everything can be easily and quickly dismantled.

Types of pipe fittings

Fittings for metal-based laminate are as follows:

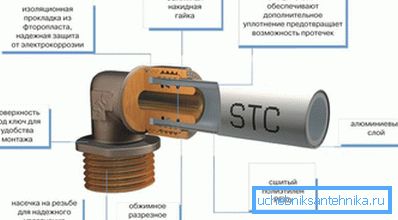

- compression (also known as "conditionally separable");

- just detachable (divided into collet and threaded);

- compression fittings (non-removable).

Of all these types of detachable usually cost more than others, because with their help you can connect or disconnect pipes many times between themselves and with various devices. This effect is achieved through the following fitting design. It consists of a brass-coated main part, an open ferrule and a rubber gasket.

For welding of polypropylene pipes with fittings, a soldering iron of simple construction is used, having nozzles for different pipe diameters.

Tip! Be sure to chamfer the outside of the pipe, otherwise, if this is not done, the pipe will be deformed when you try to insert it into the fitting. If the pipe is reinforced, you must remove the aluminum foil from the place of installation.

Metal mounting

When instead of the old it is necessary to assemble a new water supply system, it is necessary to connect the metal with the new pipes. Sometimes it can be polypropylene, sometimes it can be steel. What needs to be done to properly install?

First, you must turn off all replaceable risers and drain water from them. Then you need to unscrew the old valves, made of cast iron and very unreliable. They change to more modern ball with a flag. Then, with the help of a sanitary cable, a section of the water supply system is cleared from debris (various deposits and rust). The valve itself (new) and the filter are mounted directly - it is necessary in order to extend the service life of the faucet or appliances in the bathroom, for example, a washing machine. To create hermetic seams, a flax thread is used, which is wound on a thread along the direction of rotation of the nut. After the filter, a necessary fitting of the appropriate size is put, and a polypropylene coupling is placed on its other end. Then the new pipeline is fully assembled.