Types of plastic pipes for plumbing and installation

Nowadays, you can often meet with the pipeline, created from plastic materials, much more often than with products from other materials. This fact is connected with the fact that plastic has a large number of advantages over the other options.

But in the market you will meet with a huge number of types and options of plastic products, so many buyers are wondering how to choose plastic pipes for plumbing?

The main types of plastic used for the manufacture of pipes

In order to understand which plastic pipes are better for plumbing, you need to know all about the qualities of the product, which are directly dependent on the material used for manufacturing. In the process of manufacturing plastic pipes can be used different types of polymers.

Note! In general, all plastic products are endowed with low weight and high rates of resistance to chemical attack. Working with such products is easy and convenient, which allows for the installation of plastic pipes for plumbing with your own hands.

Polypropylene

When it comes to the huge number of advantages with which plastic pipes are endowed, most likely they are talking about products made of polypropylene.

This material is endowed with a large number of positive qualities:

- Long operational period. Experts speak about the minimum service life of 50 years and emphasize that this is not the limit;

Note! If all the rules of care and operation are followed, the polypropylene pipeline will last 100 years.

- Low thermal conductivity. This quality eliminates condensate settling on the surface and eliminates the work of insulating highways;

- Resistance to corrosion processes of various types. Polypropylene is a material that does not react with aggressive chemical solutions, which is another factor in the durability of such products and eliminates blockages due to the fact that the inside of the pipe will always remain smooth;

- Resistance to temperature extremes. Polypropylene does not lose its strength and linear parameters at elevated or low temperatures.

Council This type of plastic pipes for water supply can be used for both internal and external installation.

Polyvinyl chloride (PVC)

This type of product is also endowed with durability and durability, and in addition, the cost of plastic pipes for water supply has a much lower level than the price of products made of polypropylene. But polyvinyl chloride has a number of disadvantages, which in certain circumstances can play a crucial role.

These minuses include:

- Fragility in negative temperatures;

- Low fire resistance;

- The release of harmful substances in the combustion process.

Polyethylene (RE)

Polyethylene, as a material for the manufacture of pipes, has both pluses and minuses.

Its advantages include:

- Chemical Resistance;

- Long service life;

- Low conductivity of heat.

The disadvantages of polyethylene include:

- Low strength to mechanical stress;

- Low UV resistance;

- Low resistance to high temperatures.

Note! Pipes of this type are of two types of LDPE (high pressure) and HDPE (low pressure).

Crosslinked Polyethylene (PEX)

In order to endow polyethylene with greater strength and resistance to the effects of various temperature regimes, it is processed under high pressure conditions, observing all the standards established by GOST. As a result of this process, bonds or bridges arise between the molecules of the material.

This type of treatment is referred to as cross-linking, and, accordingly, polyethylene is called cross-linked. In order to make the connection of this type of products you can not use the heating method, so the fasteners are made by gluing or using compression-type fittings or press-fittings.

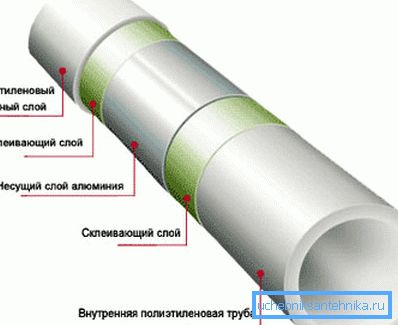

Metal-Plastic (PEX-AL-PEX)

Metal pipes for water supply are products from metal polymers, which are endowed with the following characteristics:

- The ability to withstand a pressure of 10 bar at a temperature of 95-100 degrees;

- This type of material can serve 50 years or more;

The diameter of metal pipes for water supply may be different, but a product of any size will consist of the following layers:

- Plastic;

- Glue;

- Aluminum;

- Glue;

- Plastic.

Note! It is aluminum that allows the material to bend easily, which causes its popularity in the market, and the possibility of making installation with your own hands.

Assembly process

The diameter of plastic pipes for water supply can be completely different, because This parameter is selected depending on the load on the system at a particular site.

Regardless of what the dimensions of plastic pipes for water supply, the installation of them can not do without the use of elements such as fittings.

This kind of elements are of several types:

- Crimp, compression or collet;

- Self-locking;

- Threaded;

- Flanged.

In order to answer the question of how to solder plastic pipes for water supply, you should consider the following installation instructions:

- With the help of trimming scissors, the pipe is cut perpendicular to its main axis;

- The fitting fitting of the required size is selected;

- The pipe fitting fitting and the edge of the pipe cleaned of dust, degreased with soapy water or alcohol, then dried;

- Insert the fitting and the plastic pipe into the corresponding nozzle of the soldering iron for the pipes. The fitting is worn on the drone, and the pipe is inserted to the full depth of welding in the sleeve;

- We maintain the necessary heating time;

Note! It is forbidden to take up soldering if the ambient temperature is below 0 degrees.

- Details are removed from the soldering iron and are connected to each other quickly, surely, to the full depth. With the right connection at the edge of the fitting should be formed a small continuous flow, in the form of a ring around the entire circumference;

- We withstand the cooling period, during which turns or deformations of the product are unacceptable.

Council Having no experience of soldering, make to start a few test joints, which for control will need to be cut along the axis and make sure that the structure is solid.

Connections with a node offset or part alignment must be cut or replaced. For this reason, special attention will be paid to the installer by connections created with the help of tees, angles and valves for pipes. When installing the crane, make sure that its handle moves freely in any direction.

Finally

It is safe to say that the future is for plastic pipes, judging by their relevance. The main task of the consumer is to choose the type of plastic product, because they are represented on the market in the widest range.

When choosing a product, be sure to pay attention to the labeling, because it can be used to determine the quality of the product. Well, the installation of this type of pipelines can be done independently, due to its simplicity, besides, it does not take much of your time. Therefore, read the visual instruction provided by the video in this article, and boldly get down to business.