Types of sewer pipes and connections - a brief overview

When installing the sewage system, heating and plumbing have to deal with pipes made of different materials. In order for all the work to be performed correctly, you need to know the features of the joining of pipes and their main types.

Pipe classification

In this question, it all depends on what criteria the classification is performed. For example, according to the working conditions, pressure and non-pressure systems can be distinguished.

But it is more reasonable to give a classification by material, such types of pipes are distinguished:

- Plastic, PVC is usually used for sewage, and polypropylene (PP) is used for installation of heating systems. Details on how to connect sewer plastic pipes are discussed below;

- Metallic. Steel piping is popular when installing plumbing, cast iron is used for drainage systems, there are also copper and brass pipes;

- Metal plastic - between layers of plastic there is an aluminum layer;

- Asbestos cement, for sewage is practically not used;

- Fiberglass.

Pipe docking methods

You can highlight several basic methods that are used when installing the pipeline:

- bell-shaped, connection of sewer pipes, most often is carried out by this method;

- welded - it has maximum strength and tightness compared to the others;

- threaded - threaded fittings are used;

- flange;

- using press fittings;

- use clamps.

Bell fitting

Briefly, this method can be described as follows: the end of one pipe is inserted into the expansion at the end of another section of the pipeline, additionally the connection is sealed with a sealant. In the socket there is a sealing ring, which is deformed and guarantees the tightness of the joint.

The connection of plastic sewer pipes is almost always performed in this way. Sewerage in the house works in free-flow mode, so the socket connection is enough.

Separately, it is necessary to mention the polypropylene pipeline (although it, as a rule, is not used for the installation of sewage), here also a flare joining is used, but before that the material is heated.

Due to the high temperature, polypropylene softens and the joint is completely sealed. Due to this, it can withstand high temperature coolant and pressure in the system.

Compound plastic and cast iron

People face the question of how to connect a cast-iron sewage pipe with a plastic one when they have to change part of an old cast-iron rotten sewage system. It also uses a flare, and the main feature is that it is necessary to use a rubber cuff for sealing the joint.

After the bell is cleared of the remains of the fill and sealant, its walls are coated with a sealant, then a rubber ring is inserted into it and only then the end of the plastic pipe. In this connection, the cast iron sewer pipe with plastic can be considered complete.

Note! Before you insert the plastic into the cuff, it is desirable to apply a sanitary lubricant. Otherwise, you can damage the rubber.

Features docking iron pipes

If there is no particular problem with the question of how to connect PVC sewer pipes, then in the case of connecting the cast-iron pipeline the sequence of actions changes somewhat.

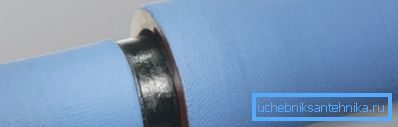

The main difference is in sealing the joint:

- a gap of about 30% of the depth is clogged with tarred jelly or jute;

- the remaining part of the gap is filled with a sealing solution (sulfur or cement mortar). It is allowed to use lead for pouring.

Note! Nowadays, the long process of capping the flare and its pouring has been replaced by special sealing rings. Their use makes cast iron sewer more resistant to deformation.

If the connection of a plastic and cast iron sewer pipe can be easily disconnected, the use of a cast iron pipeline implies a one-piece connection.

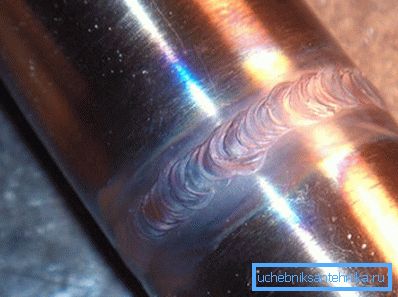

Welded joint

This method has high joint strength, but at the same time requires some skills in the field of welding metals. In addition, the one-piece joint is extremely disadvantageous in terms of its operation. Moreover, in the area of the weld metal is more susceptible to corrosion.

Therefore, welding is rarely used, mainly for installation of systems operating in pressure mode. That is, in cases where the first place comes strength (plumbing, heating systems, is also found in old sewer systems).

Note! The welded joint cannot be used if the pipeline has a protective coating, for example, galvanized. Under the action of high temperature protective layer just burn out.

Threaded connection

This type of docking is easy to do with your own hands, you do not need to have special skills.

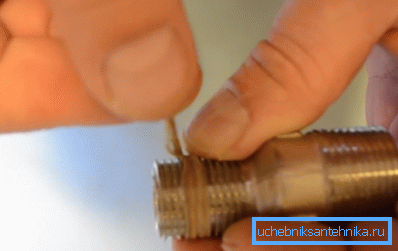

The whole operation of the docking of 2 sections consists of 2 stages:

- First, a thread is cut at both ends of the pipeline. Moreover, the thread can be cut not only on the metal, but also on plastic, the main thing is that the wall thickness allows you to do this;

- Then using a fitting with a female thread at both ends is docked. In order to prevent water from seeping through the joint, you can use flax winding.

The main advantage of this method is the ease of system maintenance. If the joint is clogged, you can always disassemble and clean the suspicious section.

Note! The only limitation in threading is the thickness of the metal. If thin-walled piping is used, the threaded connection is prohibited.

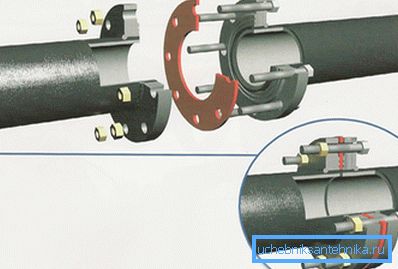

Use flanges

To dock this method, you will need 2 flanges (thick metal discs), bolts and a rubber gasket. Flanges are put on the ends of the pipeline, between them there is a rubber gasket.

The bolts are inserted into the holes along the perimeter of the flanges and tightened with nuts, due to which tightness of the joint is achieved. The price of such a joint is low, and the ability to quickly disconnect the joint, if necessary, makes it quite popular.

Flanges can be welded directly to the end of the pipeline section. The rest of the technology does not change.

Using press fittings

One of the most universal ways to dock the pipeline. Allows you to connect 2 sections without welding, threading or gluing them. For this purpose, a special fitting is used, consisting of a central part with a thread from 2 sides, clamping rings of the seal and a nut.

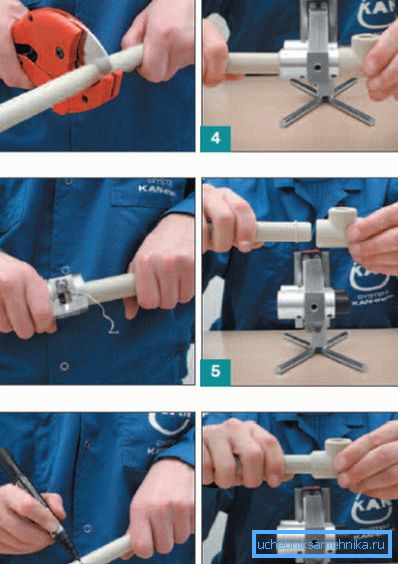

Instructions for the interface device looks like this:

- A nut, clamping and clamping rings and a sealing ring are put on both ends of the pipeline (exactly in this sequence);

- the ends of the sections are inserted into the fitting, the nut is screwed onto it. Due to the deformation of the rubber ensures the tightness of the joint.

In cases when it is necessary to join sections of a thin-walled pipeline, a pressing operation is used. Special press-pliers crimp the docking area, the metal walls are deformed and this ensures a reliable connection.

Using hose clamps

In special shops you can find repair clamps - metal cylinders with a rubber insert, tension is created by bolts. These clamps can be used with the installation of the pipeline, the main thing is not to connect the sections end-to-end, with their thermal deformation this can cause a leakage.

Given the nature of the sewer system, it provides an acceptable level of joint strength.

Clamps are almost the only way out when you need to quickly connect the profile pipe, for example, of square section. Welding will take too much time, and there are simply no other ways to dock.

Summarizing

Within one article it is difficult to consider the subtleties of the device of all types of pipeline connections. Nevertheless, the presented methods can be used for the installation of sewage systems, heating and plumbing. Subject to compliance with technology, the joints will be sealed and will last more than a decade.

The video in this article shows an example of connecting sewer pipes of different diameters.