Types of sewer pipes

What did you do before you started reading this article? You may have washed your hands or watched someone from your family do the dishes. At this point, you hardly wondered where all the water goes. And so it is - we used to treat this as something ordinary. In fact, sewage systems have been around for thousands of years. It all started with stone canals, through which the drains were collected in septic tanks. And what do we use today?

The beginning of time

In order to deal with the materials of which the sewer pipes are made, it is important to consider that they are of two main types: external and internal. For exterior work often used and used such types of products as:

- ceramic;

- cast iron;

- cement;

- asbestos.

Ceramic pipes are made of clay, then they are fired in kilns, covered with glaze, and the joints are sealed with resins. This approach ensures their almost eternal service. But their disadvantage is fragility and a very large weight. Before installing them, it is necessary to carefully inspect the joints so that there are no sinks and cracks, since subsequently water will seep through. Experienced builders can determine the quality of the sound, when tapping with a hammer should not be heard too much rattling.

Until recently, the main material for sewer pipes was cast iron. There was a lot of metal, it had to be put somewhere - that was how it was poured from it (although it still remains a relevant topic today). The main advantage of using products of this type is noiselessness during the passage of water and sufficient durability (up to 80 years). Otherwise, they are quite heavy, inconvenient to install, bulky, and a rough surface delays waste, which leads to blockages.

Tip! Over time, the metal is subjected to corrosion and the inhabitants of many apartments have to dismantle the cast-iron pipes and replace them with plastic ones. In this case, the problem is the question of their disposal.

If pipes of this type are planned to be used for external sewage, then it is very important to take into account the type of soil, since in solonetz they quickly become useless.

Along with cast iron pipes, concrete and asbestos are used. They have large dimensions, considerable weight. For their transportation it is necessary to hire special cars. Products of this type are used on highways, make it possible to manufacture wells, etc. Being resistant to chemical influences, blockages, as well as thermal fluctuations can last a long time without the need for replacement and repair. They are also easy to install, because no special connection products are required. But these materials are replaced by lighter, more reliable and easier to assemble.

Lighter, taller, stronger

Metal is becoming more expensive, you want to make the installation easier, and the production itself cheaper. Plastic is suitable for all these purposes. But here, things are not so simple, so you have to choose for specific conditions from these types:

- PVC pipes;

- polyethylene pipes;

- polypropylene;

- pipes from fiberglass.

Most likely, you have seen gray pipes in new buildings, and, perhaps, you have already managed to install them at home. They are made of PVC, or polyvinyl chloride. Such material is very easy to obtain by recycling bottles or other products. These pipes have many advantages, but there are also disadvantages. Low weight does not require special transport for transportation, it is also easy to lift them to a great height to carry out installation. Chemicals do not pose a hazard to pipes of this type. The inner surface is very smooth, so there is nothing to delay the waste and create congestion. The shape of the pipes is designed for one person to easily cope with their installation.

Tip! The disadvantage of these products is their high noise, when the flow of water rushes down. They do not tolerate high temperatures, so they are not suitable for laundry or boiler rooms.

Pipes for external use are painted in orange color, thus increasing resistance to negative temperatures. When choosing for this kind of installation it is worth considering whether the transport will exert pressure on the surface under which they will be. If the movement is intense, then it is worth picking up products that have increased strength.

If there is a need to organize a permanent discharge of hot water, then polypropylene pipes are perfect. They have all the advantages of the previous ones, except rigidity. This material has a high ductility, which, however, can be used as an advantage. They withstand temperatures up to 100 ° C without deformation and sagging.

Tip! For the installation of some types of PP-pipes it is necessary to use special fittings and a soldering iron, others are twisted by hand using threaded connectors. The advantage of this class is their long service life, non-susceptibility to corrosion and chemicals.

For trunk sewers used polyethylene pipes. They are corrugated and can be double-layered. Their diameter can reach 20–80 cm. This design makes it possible to withstand high pressure. This material is well tolerated by various soils without being exposed to them. Installation does not cause any problems, it is performed with the use of cuffs or cold welding. However, it is not recommended to use this type of product where there is a constant flow of hot water, because It can lead to deformation and failure. If the line will pass under the road, then it is placed in concrete boxes to eliminate the impact of the sinking mass.

Additional tips

For PVC and fiberglass pipes, an entire system of pipes was developed, which are very easy to assemble and assemble into a single structure. It should be borne in mind that they are of different diameters, so it is important not to make a mistake in choosing.

Tip! For end connections, plugs are used to always have access for cleaning - revision. Tees make it possible to perform a denouement. There are also many adapters for different sizes.

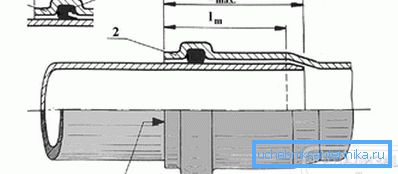

Certain inconsistencies can smooth out compensation sleeves that can move freely to connect two nozzles. Especially it is necessary to highlight the check valve, which lets the drain in only one direction, this makes it possible to prevent flooding in the house. Each fitting is equipped with a rubber seal that provides tightness. In order to make it easier to connect all the elements, they can be pre-moistened.

If you are going to independently install an outdoor sewage system, there are several useful nuances that will allow you to do it in the best possible way:

- The trench should be of such depth to take into account the level of freezing of land in a particular area.

- The trench can not be just smooth, to ensure the outflow of fluid, you must comply with the slope. For each meter, it should be about 2 cm.

- It is important to properly organize the base to prevent subsidence. Lay rubble, tamp well, then pour sand and tamp again well.

- The thickness of each layer should be 15–20 cm.

- Do not forget about the inspection wells, put them at every turn or in 25–30 m.

- After mounting the entire length of the pipes, cover with sand, tamp on the sides, but not on top. Then you can lay out the excavated soil.

- If necessary, use special insulation foam polyurethane.

Here are some more interesting uses for this kind of pipe:

- use them to organize storm systems;

- to make a gutter, simply cut the pipe into two parts;

- use standard clamps for fastening;

- branch pipes can be used for watering various plants, for this they are buried in the ground and filled with water and fertilizers.

Instead of output

Time does not stand still, new materials are becoming more common and it makes no sense to be a conservative. Many contractors and firms have long abandoned cast iron, concrete and asbestos pipes. Plastic is becoming popular. It clearly stands out with such advantages as low weight, ease of installation and no need to hire heavy equipment, unless, of course, we are not talking about the design of highways. Now there is no single standard for all possible options. There was a large selection.

If everything is correctly and correctly calculated, to determine what the load will be, what is the temperature of the liquid that will be discharged, whether it will be external or internal design, then you can choose exactly what you need, and not what you want to sell. PVC, PP and other types of plastic pipes are practically not exposed to chemicals, they do not interact with water and do not deteriorate from wet earth, and this means that their service life may exceed 100 years or more.

See also:

- Conclusion sewers from the house.

- About manufacturers of sewage pipes.

- Defrost sewer pipe.