Ventilation in a private house of plastic pipes

In order for the walls and decoration of your home to serve you as long as possible, ventilation in a private house made of plastic pipes can be realized.

Requirement, not wish

Until a certain point, the issue of ventilation of the premises was not so acute. Due to the fact that housekeeping and amenities were on the street, and one had to constantly open the doors, fresh air from outside was constantly provided. Today the situation has changed for several reasons:

- Families began to spend more time at home.

- All amenities were moved inside the premises, which increased evaporation.

- Conventional stoves were eliminated, the channels of which largely contributed to the influx of air.

- Until some time metal-plastic constructions were installed without the possibility of micro-ventilation.

- In most cases, the attic space is removed or it is used for the attic floor.

- The number of air conditioning applications has increased.

- The houses began to install saunas and swimming pools.

- With several layers of interior decoration, the exchange of air masses deteriorates even through steam passage materials.

- Strong foundation deepening in some areas leads to the intake of natural gases that can be harmful to humans.

- Cooking was often carried out in separate rooms (summer kitchens). Now this process is completely transferred to the house. Most often, the hood can not cope in order to remove 100% of the fumes.

- Distribution of forced moistening systems.

What to choose?

According to their technical data and indicators of the ventilation system is divided into ventilation:

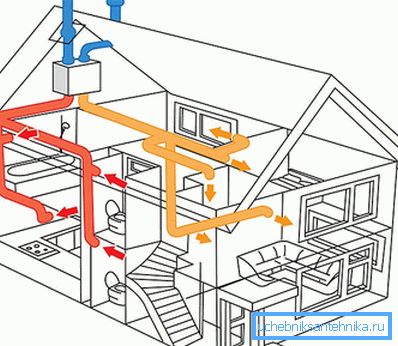

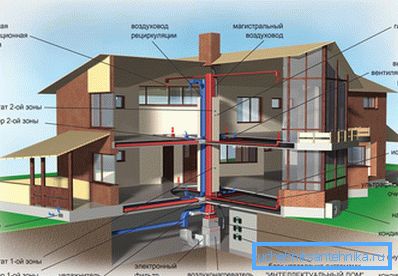

- Air intake type - air intake and purification from the street and its entry into residential premises is carried out.

- Exhaust type - exhaust air is taken from the premises and displayed on the street. Inflow through additional channels due to the pressure difference.

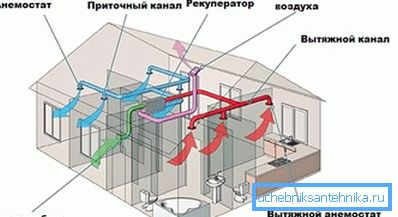

- Recuperative type - when part of the air from the premises returns to prevent large heat losses.

- General exchange type - when the circulation and exchange is carried out between all the rooms, and not each separately.

By way of installation, they can be:

- channel;

- channelless.

By way of moving air masses:

- natural circulation - volumes are replaced due to the action of physical laws;

- forced - fans come in, which are built into the channels themselves or in separate units;

- mixed - combines the two previous options.

Why plastic?

Previously, ventilation ducts were hidden in the walls and were mostly made using brick masonry. Today, the customer has the right to choose the material and method of manufacture. Modern systems are more produced from three main compounds:

- Polyethylene. This material is quite plastic and has a low weight. It is easily recyclable, so a failed system can be easily disposed of.

- Polyvinyl chloride (PVC). Some derivatives are highly resistant to oils and corrosive substances. Ducts of such material can be located even in direct sunlight without causing them harm.

- Polypropylene (PP). It is highly resistant to stress. It is also neutral to the effects of solvents and chemically active substances.

Tip! Someone is afraid of installing plastic systems due to the release of toxic substances. In fact, the method of production has reached such a level that you can not worry about it.

Compared to other materials, plastic is distinguished by:

- Low weight. One meter pipe has a mass of 800 grams.

- High corrosion resistance.

- Simplicity and high speed installation.

- Reasonableness of the design.

- The possibility of a combination of different profiles.

- Resistance to temperature changes.

- Preventing the settling of various substances due to the smooth inner surface.

- The price is an order of magnitude lower than that of metal structures.

- All types of plastic - polymeric compounds that can be oxidized by temperature.

Basic ventilation requirements

To ensure the maximum efficiency of plastic for ventilation ducts, it is necessary to analyze it in relation to the basic requirements that apply to the air intake and exhaust systems.

- Enough air intake per person.

- The right balance between supply and removable volumes.

- Removing moisture sufficiently for comfort.

- The possibility of supplying to each room.

- Resistance to fire.

- Good insulation.

- Minimum noise during operation.

- Easy to assemble.

- Exit the masses must be carried out at the highest point - usually the roof.

- The fence occurs at a height of 2-3 m from the ground.

- The movement of the total flow occurs from the living rooms and bedrooms to the places of its greatest pollution, but not vice versa.

- The total cost of the system should be as low as possible.

Only one of these points plastic loses. But resistance to high temperatures is presented at work, at home there is no such need. At other times, plastic is far superior to other options, for example, it does not need such insulation as metal when passing through the main line under the roof.

Calculation of ventilation for a private house

To make the right choice, you first need to perform some calculations:

- Determine the volume of each individual room.

- The number of family members who are constantly inside.

- Take into account all electrical devices that in any way can affect the state of the air.

- Analyze the speed of movement and replacement of air masses in the house.

- Consider whether it will be possible to hide the ventilation in the niche.

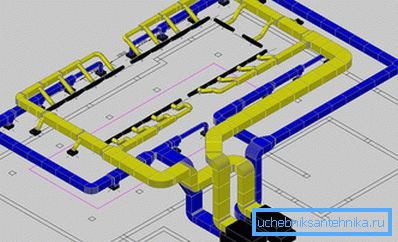

- Apply the layout to the paper plan.

- Select the profile and pipe diameter.

- Consider the area in which the house is located. If your home is located in the gas center of the city, then in the ventilation system must be present filter elements. This is very important, because then there will not be much meaning and benefit to health. When your area is a quiet suburb or a place near a forest belt, you will not need such an installation.

- Choose the place of the air intake.

Some numbers can not be found without additional equipment. Therefore, at the design stage, it is better to attract those who know their business well and will be able to give an honest assessment of the situation.

Choosing a ventilation system

Tip! An unpleasant consequence of a large draft can be the lag of wallpaper.

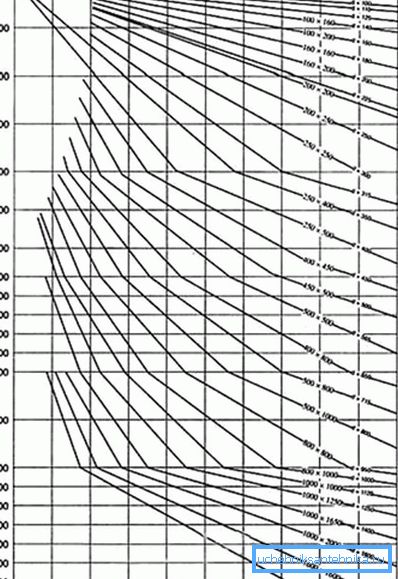

The simplest data can be obtained by taking the total area of all premises as a basis and multiplying it by 3 m.3. That is how much air should flow per hour at 1 m.2. For the outflow, the following values can be used: kitchen - 90 m3/ hour, bathroom - 50 m3/ hour, bathroom - 25 m3/hour. In order to determine the diameter of the pipe, refer to the following table:

But these are only basic numbers. It is impossible to learn everything theoretically. Instruments will be required that show how fast the masses are completely replaced in the room.

Considering all the nuances, you can see whether you really need a system of forced intake and exhaust, or if there is enough natural ventilation of the house with a plastic pipe, which is more familiar to humans.

Tip! For maximum comfort in systems with forced exhaust air velocity should not exceed 5 m / s. For natural circulation systems, this indicator is much lower and amounts to 1 m / s.

Installation of the ventilation system

Up to this point, all calculations have already been made and the necessary material has been purchased.

- Installation is best to start with the roof. This is where the main elements of the entire system will be located.

- The exhaust air pipe must rise 50 cm above the ridge. This requirement is very important to comply with. Otherwise, the turbulence, which is present on the surface of the flooring, will drive the flow in the opposite direction.

- The outlet must be well sealed. For this purpose, a special rubber cuff is applied, which is additionally sealed with silicone.

- At the end of the pipe should be an aerator that will prevent precipitation from entering the system.

- The intake pipe is usually supplied to the gable and closed with a grill.

- Then mounted air handling unit. Well, if it is with the technology of recovery. In it, part of the air that is discharged from the premises is mixed with the incoming air and warms it up.

- From this installation, the channels are routed to all other rooms.

- The pipe is fastened with clamps. They must be placed every 1–1.5 m.

- If possible, avoid 90? Angles.

- When using electric fans in pipes, be sure to consider the presence of check valves in the system. This is especially true of the bathroom as well as the kitchen. If this is not done, then the air, saturated with vapors and odors, will spread throughout the house.

- Each output in the room should be covered with a grid. If necessary, you can install it with adjustable louvers for more fine-tuning.

- If there are large areas with horizontal spans, it is necessary to provide for the possibility of dumping the accumulated moisture.

- The main wiring on the roof is best done using round pipes. The rooms can be lowered rectangular. They are easier to hide under false walls and suspended ceilings. For connection of various profiles special adapters are provided.

- Ensure that the internal surface of the pipes is antistatic. This will eliminate the settling of dust and other substances on the walls.

- If general-type ventilation is planned, all the doors should have grilles on the bottom or provide a gap of 2 cm.

- Ventilation for sewers is better not to connect with the general, for it should be a separate outlet.

Tip! It is better to collect channels block and then mount. It is not at all convenient to connect pipes that are already fixed. In this case, there may be a leaky joint.

Ventilation from sewer pipes

Methods and standards for the manufacture of sewer pipes determine their environmental friendliness. They are well suited to have vents made of them. True, there are some nuances that are worth considering:

- Mandatory anti-static treatment is required. Initially, these pipes are designed for water, and not for the passage of air through it, so this coating is not carried out in the factory.

- Consider whether it will be possible to hide a pipe of such a diameter.

- Size standards may not match ventilation systems. We'll have to use adapters. Remember that there should not be a sharp narrowing of the diameter.

It is often difficult for us to get used to things that are actually a necessity. This may be a relic of our upbringing or ignorance of some nuances. Good ventilation will be the key to the health of every inhabitant of the house, as well as the entire building as a whole.

Video

This video shows how to install a plastic ventilation box in the kitchen of a private house:

See how you can make a drain from sewer pipes:

A photo