Ventilation pipes: how to choose the material for the

Ventilation is one of the mandatory engineering networks that are designed and installed in an apartment or a private house. For its arrangement, in most cases, ventilation pipes made of galvanized steel or plastic are used. Let us consider in more detail the technical characteristics, as well as the advantages and disadvantages of each of these materials.

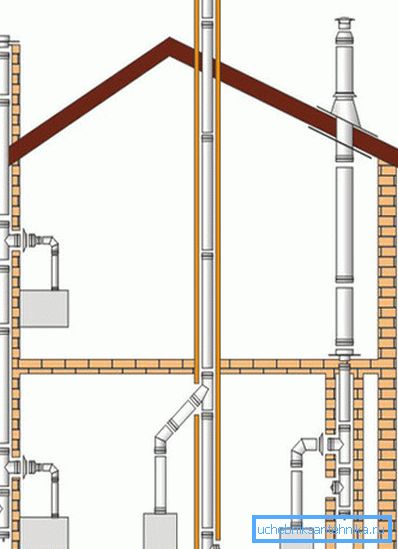

Design features of ventilation systems

Laying channels for access of fresh air into the room and its ventilation is provided at the stage of drawing up a building project. This allows you to pave the communication in the wall and not to spoil the interior space.

The optimal design - galvanized ventilation pipe, located next to the chimney. This helps to improve air thrust. However, it is not possible to locate the channel too close to the chimney in order to avoid heating from the exiting smoke.

It is advisable to make a separate duct for each room (for this, a ventilating corrugated aluminum pipe can be used), which are then output to a common channel.

Tip! If the rooms that require mandatory ventilation (kitchen, bathrooms, boiler room) are located at different ends of the house, you can equip several exit channels. This will facilitate installation and reduce cash costs.

Instructions for the construction work prohibits cross ventilation ducts with other pipelines (sewage, water supply, gas pipeline). Also, you should not run these engineering networks in pre-assembled air ducts.

There are two main types of ventilation channels:

- built-in, which are laid out of brick;

- external (hidden or open), for the manufacture of which PVC ventilation pipe is used or galvanized.

The second option is less labor intensive and is becoming more common. Moreover, the low price of ventilation pipes can significantly reduce the cost of construction, and easy installation allows you to do everything yourself, without the involvement of expensive professionals.

As already mentioned, for the arrangement of air ducts are used parts of circular and rectangular cross-section, made of the following materials:

- Galvanized sheet metal. Most often, such systems are laid in public buildings, offices, production shops and other premises that have a high degree of explosion hazard (corrugated ventilation pipe is the most common option for ventilation of large shopping centers).

- Plastic parts. A ventilation pipe in a private house is often made of polyvinyl chloride or another similar polymer. This facilitates installation and reduces the estimated cost of construction without degrading the technical characteristics of the ventilation system.

Selection of pipes for ventilation

General requirements

Regardless of the material of choice, the ventilation systems in the residential or commercial premises must meet the following requirements:

- be completely sealed;

- create conditions for the smooth passage of the required volume of air at a projected speed;

- comply with the sanitary and hygienic standards on the level of noise;

- to be fireproof, resist burning and contribute to the attenuation of an open flame;

- most organically fit into the design of the premises (especially when open laying).

For joining individual elements, special fittings are provided for connecting pipes. The diameter of the ventilation pipe and the dimensions of the flange elements must be the same, otherwise it will not be possible to achieve a tight connection.

However, modern industry produces a huge number of different parts for designing ventilation of the desired size, so there will be no problems with the selection and purchase.

Note! PVC ventilation parts are not susceptible to corrosion. Because they do not need to isolate the passage of interfloor and attic floors. According to this parameter, they are preferable to galvanized, on the outer walls of which condensate may form. Such products must be protected with glass wool.

Galvanized ventilation ducts are indispensable for providing ventilation of rooms where there is a risk of fire. They will not melt even under the influence of open flame. But in a private house, their use is less justified, especially since they can make a strong unpleasant noise when turbulent air flows occur.

However, the installation of a common duct near the chimney is possible only with the help of parts made of galvanized.

Tip! If ventilating flexible pipes are used for duct installation, it is not necessary to do many turns, otherwise the noise cannot be avoided.

Rigid or flexible parts

On sale there are rigid and flexible designs. Rigid - there are round and square section - are used for the installation of most of the ventilation system. Flexible are necessary for arranging a small section of the duct, if you need to make several difficult turns at once.

Features of flexible pipes from plastic and metal are given in the table.

| Metal | Plastic |

| These parts are made of metal foil, folded in several layers. + have a corrugated structure + can be bent in any direction - ribbed inner surface creates additional resistance to passing air | It is made from polyester and aluminum foil. + have a solid structure, additionally reinforced with steel wire + have low thermal conductivity and good sound insulation - can not be used for laying channels in rooms with a fire hazardous environment |

Installation Features

As for the installation, here the absolute leader can be considered plastic parts.

Let us dwell only on the main advantages:

- Low weight. Polymer pipes are easy to transport and install without the use of specialized engineering equipment.

- To hang the structure does not need to install a large number of mounts. Due to the ease, the sagging of channels is excluded.

- Plastic for ventilation is easy to cut into pieces of the desired length and mounted using fittings and adapters. The installation process of galvanized ventilation pipes is more laborious and time consuming.

In addition to the advantages listed above, plastic pipes for ventilation have an antiseptic effect. Bacteria do not breed on their smooth inner surface, and dust and debris passing through the ventilation does not get stuck.

Therefore, the ventilation system made of plastic does not require such frequent maintenance as air ducts from galvanized. It is these factors that led to the fact that the vast majority of ventilation networks are currently being constructed from polymer parts.

Use of sewer pipes

For the installation of air ducts, a galvanized ventilation pipe of 100 mm and 110 mm is used. The same diameters have polymer parts. Pipes for sewage treatment (for example, a corrugation connecting the sewer outlet to a pipe) are 120 mm in size.

The question arises, is it possible to use drain pipes and corrugations for arranging ventilation channels, because their price is much lower?

Here you should follow these rules:

- The outlet should be wider than the inlet duct. Therefore, it is not recommended to attach a 120-mm corrugation to 110-mm ventilation.

- Many believe that this transition does not affect the functionality of ventilation. They seal the compound with adhesive tape, sealant and other similar materials. However, the air flow, passing through such a step, will create turbulence, which will greatly reduce the efficiency of the system.

- If necessary, to equip the transition, you should use adapters with a smooth narrowing, which will ensure the smooth passage of air flow.

Conclusion

Choosing plastic or galvanized for arranging ducts, do not forget about how to connect the ventilation pipes. After all, both the efficiency and durability of the engineering network operation depend on the quality of the docking. More details about this can be found in the video in this article.