Water fittings are an indispensable element when installing

The plumbing or piping of the heating system in the apartment cannot be laid without connecting individual segments of pipes. Also, it is impossible to do without sharp turns, as well as branching of the pipeline. Given this fact, we can not do without special devices - fittings that provide a reliable, tight connection.

Types of fittings

It is quite difficult to give a complete classification because much depends on what is the basis for the division into groups.

For example, if you use the connection method as the main criterion, you can select only 2 types of such devices:

- one-piece - welded pipe joints can be considered a classic representative of this group. For example, plastic plumbing and fittings from the same material (polypropylene) are simply heated by a special soldering iron and then the pipe is inserted into the socket; when it hardens, the joint is tight;

- separable - as an example, a threaded joint, if the pipes are metal, the thread can be cut on the pipe itself. Also, compression fittings can be used, the connection with a cap nut is very simple and convenient;

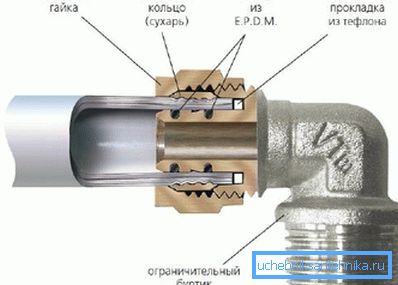

- conditionally detachable - connection, for example, metal-plastic pipes using a cap nut and crimp ring formally, though classified as a split, but if necessary, it is often changed entirely.

As for the material from which these connecting elements are made, you can select:

- metal (most often we are talking about brass models);

- plastic - mainly polypropylene and polyethylene are used for plumbing, so also plastic fittings are used;

- Combined, for example, in polypropylene water outlets, the body is made of PP, but the inner part, the one to which the mixer is connected, is made of brass.

Regardless of which particular models are used - plastics plastic or metal fittings, for the intended purpose they can be divided into:

- corners, bends - they are used in the case when you need to ensure the rotation of the pipeline at a certain angle. The angle of rotation changes with a certain step;

Note! Some pipes, such as metal-plastic, metal can be bent during installation. This minimizes the need for connections and provides a smoother rotation with minimal pressure loss.

- coupling - a section of the tube for simple connection of two ends of the pipeline;

- to create a complex knot, such an element as a crosspiece is useful, and a ball valve with a servo drive installed on it will also allow to regulate the flow movement, if necessary, dividing it into 2 circuits;

- if you need to "multiply" the flow of the main pipe, then tees are used - fittings for tapping into the water supply system;

- You can also note a variety of plugs and adapters - they are used when you need to connect 2 pipes of different diameters.

Brief description of popular in-house fittings

Quite often, all the work on the installation of plumbing, heating and sewage in a house is done by the person with his own hands, therefore, a short description of the fittings used for this will be useful.

Metal pipe connection

The simplest solution is to cut the threads on the ends of the pipes and connect them, after performing the FUM underwrap with tape or regular tow, sometimes welding is also used. Flanged connection type in the home does not apply.

Recently, joints using a cap nut and a compression ring have become more common. The union nut is simply put on the pipe, then the compression ring, the retaining ring, the sealing gaskets. Then the nut is screwed on first with your hands, and then with a key on the threaded part.

Note! If a threaded or welded joint is able to withstand a significant mechanical stress, then a crimp is not. The compound can, if desired, be destroyed with bare hands.

However, this type of pipe connection is popular. First, it is unlikely that in the process of exploitation it will have to withstand considerable efforts. And secondly, the price of such a fitting slightly exceeds the mark of 100 rubles, for the family budget - the value is absolutely imperceptible.

Fittings for plastic pipes

In the case of plastic piping, there are also several connection options. Polypropylene connecting elements are issued for welded connection.

Instructions for performing work looks like this:

- the pipe is cut, the cut must be smooth without bevels;

- then you need a special soldering iron. The heating element is a bit like an iron, on which small sections of metal pipes of different diameters are located. After this part is warmed to operating temperature, the fitting and the pipe itself are put on it;

- after waiting a couple of minutes the pipe is quickly inserted into it. It is important that there is no skew. Part of the molten plastic will squeeze out at this, forming a bezel around the joint - this is absolutely normal.

Quite often, HDPE pipes (low pressure polyethylene) are used to lay the outer part of the water supply.

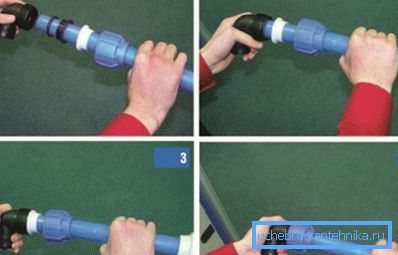

The number of connections in this case is minimal, PND compression fittings for water supply are used - its device is almost identical to conventional crimping models:

- instead of a cap nut, a plastic cap-nut is used;

- the body of the device is made of polypropylene;

- To achieve a tight joint, rubber rings are used.

The ends of the pipes are connected in exactly the same way as with conventional crimp models. That is, a cap-nut and a sealing gasket are put on the pipe, then the end of the pipeline is inserted into the body up to failure, and the nut is screwed onto the thread.

Note! PND is extremely sensitive to UV radiation, it is desirable to limit the time it stays in the sun.

As for reliability, plastic fittings for water supply have no particular disadvantages. The only weak point is the sealing ring, sometimes it can cause a leak. So periodically the cover nut will need to be tightened.

Summarizing

The laying of any pipeline is almost impossible without the use of fittings. The variety of these devices allows you to organize a system of any complexity, while the installation of this element will not cause difficulties. Together with the low price and reliability, this ensures the demand for fittings of various types.

The video in this article shows an example of installing multiple HDPE fittings.