Welded pipe 108 - an indispensable building material

Despite the appearance of plastic pipes, the steel pipe does not lose ground. Metal plumbing, heating and sewage systems remain quite popular, and pipe steel can also be used as supporting elements of the framework. For example, a pipe 108 by 4 may well be used as a stand for the frame of a light construction.

General information about the electric welded pipeline

Steel pipe for more than a decade has been used not only for laying plumbing or heating, but also as a building material. The scope of application of welded pipes is much wider than it might seem at first glance. Depending on the purpose, the composition of the steel is different, and the requirements for rolling are different.

Classification of electric welded pipes

Depending on the destination, it is possible to distinguish the following pipe rolled products:

- Class 1 - used in everyday life. This group includes the pipeline, which is used, for example, for the installation of a heating system. Even a non-specialist will cope with the installation; only detailed instructions for the work will be needed;

- Grade 2 - with increased resistance to pressure and temperature. This type of rental is used for pumping oil, as well as water in the main conduit;

- Grade 3 - the composition of the steel is selected on the basis of frequent changes in temperature and pressure. Scope - food industry, chemical industry, etc .;

- Class 4 - pipeline subjected to hard mechanical stress, for example, when drilling a well. Steel should have increased resistance to wear;

- 5 class - this rental is mainly used as bearing elements for frames. Accordingly, the main requirement is high strength and low price;

- Grade 6 - is produced to meet the needs of the engineering industry. The main characteristic is increased resistance to high pressure, abrasion resistance.

Normative base

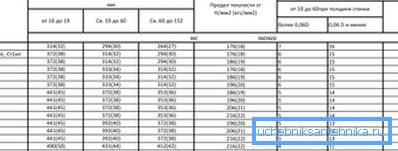

You can select several standards, geometrical dimensions, weight and tolerances can be found in GOST 10704-91, it also contains basic information on the dimension. For example, pipe 108x4 according to GOST 10704 91 cannot be produced with a length of less than 4 m.

In general, the dimension depends on the diameter:

- more than 426 mm - as a rule, the size is determined by agreement with the customer;

- more than 152 mm - the minimum length is 5 m;

- 70 - 152 mm - 4 m;

- 30 - 70 mm - 3m;

- less than 30 mm - 2 m.

The range of sizes is quite large: the diameter varies from 10 to 1420 mm, and the thickness of the metal can be 1 to 32 mm. Accordingly, the weight of the pipeline is very different. For example, the weight of 1 meter of pipe 108x4 according to the standard is about 10.26 kg, and with an increase in metal thickness to 5.0 mm, this figure rises to 12.70 kg.

Note! When marking is always indicated outer diameter. In order to find out the inner diameter, it is necessary to subtract from this number twice the thickness of the walls.

In addition, the document must also take into account a number of technical conditions. This data is important at the pipeline quality control stage.

You can select such documents as:

- GOST 10705-80 - information concerns pipelines with a diameter of 10–530 mm (low alloyed and carbon steel). The document contains a list of rules for acceptance, testing, the maximum permissible concentration of impurities, etc .;

- GOST 10706-76 - the composition is about the same, but the requirements in this document are applicable to pipelines with a diameter of 426 - 1620 mm;

- GOST 10707-80 - puts forward requirements for cold-formed welded pipes with a diameter of 5-110 mm (carbon steel);

As for seamless hot-rolled pipes, for them the main information is in GOST 8731-74. The absence of a seam makes the pipeline even more reliable, although a thick wall also increases the mass of the pipe, for example, the weight of a 108x6 pipe is already 15.09 kg / bar. m

The main stages of production

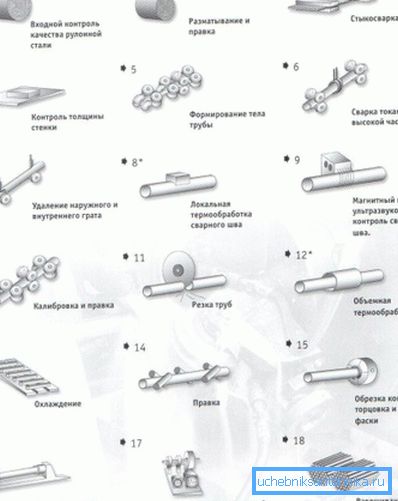

The entire production process can be divided into several stages:

- a metal tape of constant width acts as a raw material. It is molded and butt-welded so that a continuous steel strip of constant width is obtained. Be sure to control the thickness of the steel, depends on the weight of the pipe 108x4, and any other size;

- in the next stage, the strip passes through a train of rollers, which give the strip the shape of a future pipeline (so far no welding is performed);

- welding is performed;

- grat is removed;

Note! A bur must be removed not only from the outside, but also from the inside. If the pipeline will operate in the pressure mode, then an unreleased burring inside will disrupt the flow of the fluid.

- after that, the strength of the seam is monitored, the pipeline is cut, the ends are cleaned of burrs. If necessary, surface dressing is performed;

- the finished pipeline is stored.

When controlling, you must take into account the method of welding. So, if a seam of increased strength (GOST 10706) was used, then the mass should be increased by 1%.

That is, if the weight of the pipe 108x5 was 12.70 kg / bar. m, then when using a seam of increased strength, it will be 12.827 kg / pog. m. With large volumes it matters.

Examples of the use of electric pipelines

In individual construction, it is usually used for the installation of heating systems, plumbing. All work is usually done by hand. Small sizes can be used as frame elements of pipes for light structures, such as gazebos.

As for large sizes, you need to take into account the price. So, the cost of 108x4 pipe is quite high (about 30,000 - 33,000 rubles / ton), so it makes no sense to use it, for example, for sewage.

In industrial construction, the advantages of an electrically welded pipeline are fully manifested. Large sizes can be used both as racks and for covering large spans. In the latter case, you have to resort to the creation of farms.

The own weight of the pipeline will not allow to block the span of a single pipe. For example, the weight of a pipe 108x3 5 is 9.02 kg / bar. m., with a span of 15.0 m only its own weight will be 135.3 kg.

Summarizing

Electrowelded and seamless pipes are popular not only individually, but also in industrial construction. Small sizes are often used in everyday life, but the larger diameter is also suitable for a more serious construction.

The video in this article describes in detail the process of producing electrically welded longitudinal pipes.