Welded pipes: their use, types and methods of production

This product is manufactured on a pipe-welding mill from a metal strip, sheet or tape. It has a wide scope of application and therefore must meet the diverse requirements set forth in regulatory documents. You can read below about what are used and how welded pipes are created according to GOST.

The use of welded pipes

Engineering technologies are rapidly advancing, but despite this, the production of welded pipes still remains in demand. The fact is that in the near future there is no substitute for this product, especially during the construction of buildings and installation of communications.

In total, there are two main types of such goods:

- universal products - they are used in a wide variety of areas for a wide range of purposes;

- highly specialized - they are used for any particular area. Most often it is the gas or oil industry.

Most often, these structures are used for the following purposes:

- installation of heating, gas and water networks - this applies to both underground and above-ground communications;

- creation of technologically sophisticated equipment - for example, these may be land reclamation systems used in agriculture;

- construction of buildings - welded pipe structures are used here as light and durable reinforcement.

We should also mention that stainless welded pipe has found wide use for itself. It is indispensable for a number of sectors of the economy, such as the pharmaceutical, chemical and food industries.

Due to its aesthetic properties, architects and designers consider it very attractive. Therefore, stainless pipe products can often be seen among the elements of architecture and design.

Advantages of welded pipe material

Pipe rolling, created by welding, has weighty advantages.

We describe them in detail:

- Efficiency - modern technologies allow you to create the most durable welded joints. Thanks to them, the pipe created with the help of welding is in no way inferior to all-metal samples. This allows you to put it where previously only seamless products could be used. This leads to good savings, since the price of prefabricated products is significantly lower than their cast counterparts;

- Lower weight - welded structures, compared to all-metal samples, have thinner walls, which significantly reduces the weight of the product. This simplifies the process of transportation and subsequent installation of elements. After all, it requires less participation of technology and people;

- Smaller deviations in thickness - this is due to the fact that welded products are made of sheet steel, which is uniform throughout its length. The accuracy of the forms facilitates the installation of the welded product.

Types of welded pipes and GOSTs on them

There are three main varieties of such products:

- constructional;

- pipeline;

- trunk pipes.

Their brief description is presented in the form of a table.

| View pipe | Characteristic |

| Constructional | Manufactured in accordance with the requirements of GOST № 10704-91, as well as GOST № 10705-80, with the exception of indicators for hydraulic testing. They are not important in this case, since this type of product is not used for transporting liquids and gases. Welded electrofusion pipe according to GOST 10704 91 is made of steel grades St2, St3 or St10, St20. |

| Pipeline | Unlike the previous type, for these products it is extremely important to comply with the indicators for hydraulic pressure. After all, it is these products that are used to create pipelines through which various liquids and gases move. Therefore, it is checked at a pressure of from 30 to 60 kgf / cm2. Depending on the required strength, these goods are made from steel of grades St2, St3, or St10, St20. |

| Trunk | Pipes intended for main gas and oil pipelines are created in accordance with GOST 2095-85. They have a diameter of 159 mm or more. They are necessarily subjected to hydraulic tests according to GOST No. 3845-75. Used steel grades - St10, St20, and 09G2S and 17G1S. |

Tip! It is preferable to purchase goods made of steel St10 and St20, since these particular brands of material are of the highest quality.

Manufacturing technology of welded pipes

Today, there are a number of technologies that make welded tubular products.

The most common are the following methods:

- furnace welding;

- electric welding;

- shielded gas welding.

Consider them in turn.

Furnace welding

This technology uses a special blank for welded pipes - strip. So called steel strips of which the final product is made.

Its creation is as follows:

- The strip enters the tunnel-type furnace and sets about 1300 ° C;

- Immediately after leaving the oven, the side parts of the strips are blown with air, due to which they warm up to 1,400 ° C and are clean of scale, which improves the quality of the future weld;

- Further, the workpiece is passed through a molding-welding mill. It gives the desired shape to the workpiece;

- Air is blown again, after which the edges of the strips are welded under high temperature and pressure;

- The final stage of the work is re-pulling the product through the furnace and forming rolls. This makes the seam more durable.

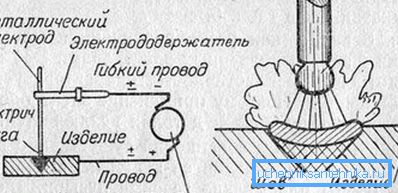

Electric welding

The aforementioned GOST for steel welded water and gas pipes number 10704-91 regulates the characteristics of electric welded products, which are the most common. This results from the fact that electric welding allows to create the thin-walled production having the big diameter and high quality of a seam.

Note! There are several varieties of such a compound, but the most used is submerged-arc welding.

Let us dwell on it in more detail.

The following instruction for creating electric-welded pipe products will help you to get a general idea of this technology:

- Initially, cold steel sheets are molded on rolling mills. The result is tubular billets;

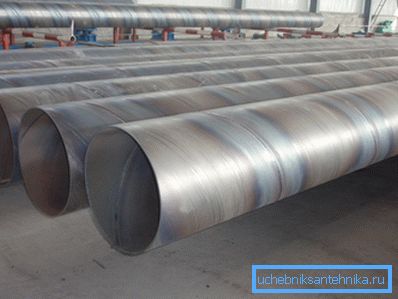

- With the help of electric arc welding, the edges of the blanks are fastened to each other. As a result, a straight or spiral seam is obtained;

- The product is cooled with water and enters the calibration mill. It allows to achieve the same diameter throughout the pipe;

- The seams of the resulting product are checked. First visually, then using ultrasound. Hydraulic tests are then carried out to determine if the pipe will withstand high internal pressure. The verification is completed by the re-use of ultrasound, after which the finished product goes to consumers, who will assemble it themselves.

It should be noted that roll forming is used to create a longitudinal pipe-rolling of various diameters. If you need to produce semi-cylinders or round billets of large diameter, press molding is used. Spiral design are made on roll-mandrel or sleeve mills.

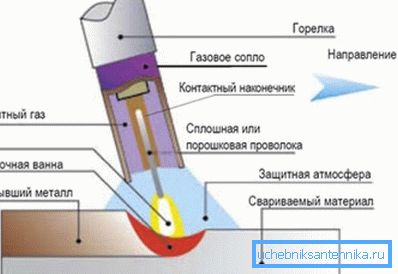

Shielded gas welding

This method is used to create pipe products from stainless as well as high-alloy steel. It allows you to get a more reliable seam thanks to the use of protective gases. These are argon, helium, and carbon dioxide.

Their use allows combining the advantages of electric and gas welding in one technology. While in the weld pool, the protective gas displaces atmospheric air from its cavity.

As a result, the quality of the seams is improved. They become uniform and durable. For such work, special tungsten electrodes are used. The downside of this process is the higher cost of pipe weld compared to other technologies.

Conclusion

Welded pipelines are used in the creation of various engineering networks, complex technological systems and the construction of buildings. Compared with all-metal counterparts, they have less weight, more affordable price and less significant deviations in thickness.

It is possible to classify welded pipe-rolling by various criteria, but the most common is its separation by purpose. In accordance with this emit structural, pipeline and main products. The first of them are used in construction, the second - in the creation of engineering networks and technological systems, the third - in gas and oil pipelines.

In the production of welded rolled products, furnace welding and electric welding technologies are used, as well as welding in protective gas is used. The most common is the first method, since it is the least expensive and allows you to create thin-walled products.

The strongest connection is provided by welding in shielding gas; at the same time, it is the most costly method. For more information on this topic, you can find out by watching the video in this article.