Welding of polyethylene pipes: instructions for independent

For years, the most popular and popular material for the construction of water supply and heating systems were metal pipes. Today, they are being replaced by polymer analogs, and as a result, instead of traditional threaded fittings, welding of polyethylene pipes is used.

In this article we will talk about what is the process of welding polymer products and how and with what tools, such work is performed.

Advantages of the welded joint

Welding of polyethylene pipes requires the availability of experience and the use of special tools. Why the choice of this type of connection of pipeline elements is considered more promising in comparison with the use of traditional threaded pipe fittings.

There are several reasons for choosing a welded joint and among them:

- long service life, regardless of the quality of the transported liquid medium;

- no need for regular maintenance;

- short deadlines for installation;

- reasonable price of a welded fitting;

- absolute absence of leaks provided proper installation;

- aesthetically appealing look of the finished pipeline.

Pipe selection

Did you decide to install the plumbing or heating system yourself?

In this case, it is necessary to determine which pipes are suitable for making the welded joint.

- A universal solution is polypropylene pipes, which are specially designed for installation by means of a thermal connection.. Such structural elements with the same success are used for the device, both cold and hot water. In addition, polypropylene (PP) pipes - this is the optimal solution for arranging heating systems, including systems, "warm floor".

- For the device of cold water supply, you can use plastic (PE) and polyvinylidene fluoride (PVDF) products with the marking PN 16. Such pipes are relatively inexpensive, but withstand a working pressure of not more than 1.6 MPa.

- For the device of heating and hot water can be applied plastic pipes labeled PN 20. Such products can withstand a nominal long-term pressure of up to 2 MPa.

Important: The market has a limited selection of polypropylene pipes reinforced with aluminum foil. Such products on a cut are similar to metal-based laminate, but are intended for installation by welding.

Varieties of welding devices

Modern equipment for welding of polyethylene pipes is represented by a wide range of more or less high-tech devices, which differ in design, brand of manufacturer and, of course, price.

Almost all devices for thermal connection of polymer pipes and fittings, despite the external features, have many similar features. In the design of any soldering iron there is a heating element, a voltage supply regulator, which is responsible for the intensity of heating and a housing with handles.

But, despite the obvious similarities, all soldering irons on the market can be divided into the following categories:

- Device for manual welding - designed to work with polyethylene and polypropylene pipes.

The principle of operation of such devices consists in processing the joints between the pipe and the fitting. The use of such soldering irons is possible if the diameter of the welded parts does not exceed 50 mm.

Important: Rarely there are manual modifications that work with a diameter of up to 125 mm.

- Mechanical devices are designed to work with pipes with a cross-sectional diameter of 50 mm and more.

The main advantage of mechanical devices is operational versatility. Such soldering irons work with most varieties of plastic pipes.

The disadvantages of mechanical equipment include the high price and complex management, which not every beginner installer can handle.

In accordance with the configuration of the heating element, flat (xiphoid) and core household modifications are distinguished. According to most experts, the use of rod modifications is more preferable, since such devices allow working in hard-to-reach places or cramped conditions.

Choosing a welding device for domestic use

As already noted, all soldering irons for pipes can be either manual or mechanical by principle. Moreover, if the former are designed to work with small diameters, then the latter are suitable for industrial use.

Since most novice installers acquire a tool for building household pipelines, it is the manual modification that is the best choice and there are obvious reasons for this:

- Hand tools solder pipes with a cross-sectional diameter of up to 50 mm. At the same time, the majority of domestic heating and water supply systems are built using pipes of this diameter.

- Hand tools are relatively compact and easy to use, which is important for beginners.

- Hand tools are many times cheaper than mechanical counterparts, and therefore can be purchased specifically for a one-time installation.

What to look for when buying a home appliance:

- Completion - devices are delivered in sale in the form of a set with a certain number of nozzles. The more impressive the equipment of the purchased device, the better. The best choice are sets with a set of nozzles for pipes with a diameter of 16, 32, 50, 110 mm.

- Power is an important parameter, since it depends on it how quickly the installation will be carried out. As a rule, for the device of household pipelines modifications with the maximum power up to 1 KW are quite enough.

- A brand is not the most important parameter, since it is not so much the brand of the manufacturer that is important, but the country where the device is made.

It is preferable to buy not Turkish and not Chinese products, but devices made in Europe, for example in the Czech Republic. Such devices are not much more expensive, but the difference in price is fully justified by the high quality and reliability of the instrument.

How to solder

Important: Before soldering domestic water supply or heating systems, you need to practice on unnecessary pieces of pipes.

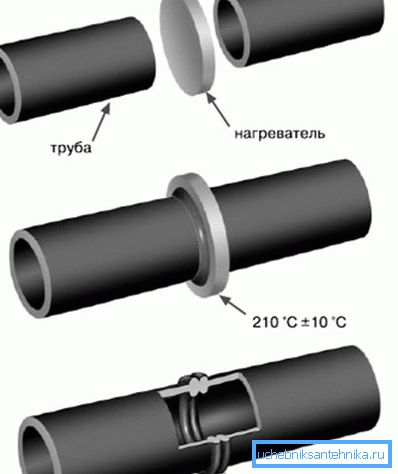

Instructions for welding polyethylene pipes are as follows:

- we cut the pipes to the desired length with special scissors;

- heat up the soldering iron;

- We put the fitting on the side of the soldering iron, where the narrower heating sleeve is located, and the tube is inserted into the corresponding hole on the other side;

- count up to about 15, after which we remove the pipe and fitting;

- Insert the pipe into the fitting and wait until the plastic cools down.

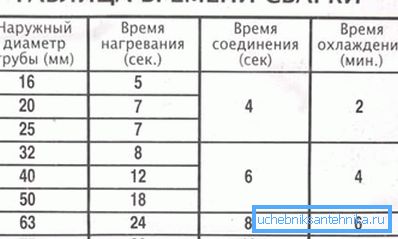

Important: The instructions given are suitable for welding household systems made of plastic parts. For work with larger diameter parts made from other polymeric materials, special tables will be useful, where the ratios of diameter, wall thickness and time required for heating are indicated.

Conclusion

Now you know how, and with what equipment, polyethylene pipes are welded. The above information can be applied in practice, choosing a soldering iron and performing installation of the pipeline.

There are questions that need clarification? Answers to them you can find by watching the video in this article.