What are the heating pipes and how they are mounted

Depending on the material, all heating pipes can be divided into three large groups: metal, asbestos-cement (chrysotile-cement) and polymer, although each of the categories has its own varieties and features in use. Each of all listed types can be more or less appropriate in one way or another, which is coordinated with the place and method of installation, pressure and, of course, the desire of the customer. We will have the opportunity to discuss the general characteristics of such structural materials.

Communication materials

Metal

- For heating systems with any pressure, pipes from different metals are used, among which black and stainless steel, cast iron, copper and aluminum can be called.

- Also relevant are combinations of two materials, for example, steel-aluminum or steel-copper, or bimetal.

- If we talk about strength, then in the first place will certainly be steel, on thermal conductivity - aluminum, and on practicality - bimetallic systems.

- Bimetals are not used for highways and contours - here can be used black and stainless steel, cast iron and copper. All these materials (with the exception of stainless steel) have one serious drawback to asbestos-cement and polymers - susceptibility to corrosion or oxidation.

- Nevertheless, if we talk about the main pipelines, then black steel and cast iron are found there most often, and copper is more used for premises, especially since its price is quite high.

Note! Very effective, especially for country houses, heating by air through the pipes, which is possible for furnaces like buleryan. The furnace itself is very economical, due to the secondary afterburning of the fuel, and a high heat transfer coefficient is achieved thanks to the steel pipes entwined around it.

Asbestos cement

For the most economical heating mains, perhaps, chrysotile cement pipe can be called - it does not require powerful insulation, as it has a sufficiently low thermal conductivity. Moreover, its deformation rate when heated is 12 times lower than that of steel, therefore, for installation, expensive compensating couplings. Due to its composition, asbestos-cement does not form organic growths, therefore, the permeability or hydraulic resistance practically does not decrease there.

At the same time, the instruction on asbestos-cement pipes notes their fragility (despite the reinforcement) - they are afraid of strong impacts and jolts during transportation. When installing such pipelines, it is mandatory to conduct two visual inspections - one after unloading at the trench, and the other - after laying. Docking is carried out using uniform couplings with rubber seals.

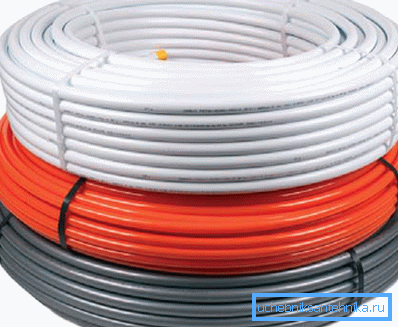

Technopolymers

- In recent years, polymer pipes have increasingly been used for heating systems or their circuits, which are increasingly replacing various metal analogues.

- Perhaps, a part of such popularity is connected with the fact that it is easy to assemble them with your own hands, which is what many owners use, saving money on attracting specialists (welders).

- Polyethylene and polypropylene fall into the category of polymers, but we'll talk about it in more detail below.

Note. In the documentation instead of the full name of the material, it is often possible to find its abbreviation. Thus, polyethylene is referred to as HDPE / LDPE or simply HDPE / LDPE (low and high pressure, respectively), HDPE / LDPE (international version), and polypropylene PP or PPR (international version).

Overview of Polymer Products

Polyethylene and metal plastic

Among polyethylene pipes, we are primarily interested in LDPE (cross-linked PE) and metal-based laminate - they are not used for radiator circuits, but they cannot be avoided when installing a floor heating system.

- For this purpose, cross-linked PE with a diameter of 16 mm can be used - the nominal pressure here is allowed up to 10 bar, and the maximum operating temperature is up to 110? C.

- Such characteristics suggest that the pipes can be used with any stand-alone boilers, and even if the coolant is supplied from centralized heating.

Note! This scheme can be implemented only with autonomous heating. To connect a warm floor to a common battery means to risk getting a fine and dissatisfaction of neighbors.

- The disadvantage of such a polymer can be called its insufficient stiffness - as is known, the contour is placed on the screed, after which it is poured with another layer of solution and if the pipe is not filled with water during such an operation, then it can be deformed.

- Fixing to the subfloor is carried out with special tape clips, with the help of which it is convenient to withstand a certain paving step and distance from the wall, so that the plinth under it does not cause damage.

With the same success, metal-based laminate is used for floor heating; moreover, most plumbers prefer this material, PE - it is more convenient to lay it and, moreover, the cost of metal-based laminate is somewhat lower than LDPE.

- Such a pipe has three main layers - the inner one of the LDPE, the middle one - of aluminum foil and the outer one - of the HDPE. All of them must be bonded with glue (for quality products).

- If there is a need for sharp bends, which cannot be avoided when laying with a snake, then a piece of steel spring (20-25 cm) is put on the pipe, the inner diameter of which is several millimeters larger than the pipe section, that is, 18-20 mm.

- This spring is pushed into place of the bend and gradually, as it is laid, it is pushed forward to the very end.

- When it is necessary to install a laid-on thermometer on the heating pipe, this is done not in the floor, but on the distribution node, which is most often embedded in the wall.

Popular models

To find out which products are suitable for the heating system and which are not, the table below will help:

| Pipe type | Purpose | Maximum temperature in continuous mode | Nominal pressure (atm / MPa) |

| PN10 | Cold water | 20? C (briefly 45? C) | 10.2 / 1.0 |

| PN16 | Cold water | 40? C (briefly 65? C) | 16.3 / 1.6 |

| PN20 | Cold and hot water, heating | 80? C (briefly 100? C) | 20.4 / 2.0 |

| PN25 | Cold and hot water, heating | 95? C (short term 150? C) | 25.5 / 2.5 |

PPR Summary

For radiator circuits (including this may be a single-pipe heating circuit), modifications of polypropylene RN20 and RN25 are used, although the latter is mainly intended for such purposes.

The fact is that, as you can see from the table above, the working temperature for the RN20 reaches 80? C, and the optimal mode of the convection boiler is 60-80? C, therefore, there are no violations here.

But still, if you think that the working (constant) temperature of the circuit will exceed 80? C, then of course you better use RN25.

Note. In RN 25, aluminum foil is not located in the middle of the wall, but closer to the surface and this will interfere with the welding work. Therefore, to remove it, use a shaver for stripping the top layer and foil. It should also be noted that for radiator circuits of the invoice thermostat on the heating pipe can be mounted in any place convenient for you.

If you are interested in how to close the heating system, for this you can buy in a store or make yourself, as in the top photo, decorative grilles that mask not only radiators, but (if necessary) and pipes. PPR is fixed to the wall with metal brackets or plastic clips.

Conclusion

If you decide to install PPR in the wall - the pros and cons are obvious, although technologically it does not matter to the circuit. The advantage here is that you simply remove the pipe from the view, while not having any heat loss. But the negative side is difficult to call, except that the increase in labor intensity during the installation of the circuit. The video in this article will help in more detail to understand this issue.