What are the pipes for water: dimensions, types of

By and large, the answer to the question of what kind of water pipes can sound differently - it all depends on what parameters they are classified by. But their classification can be distributed according to the type of surface insulation, according to the cross-sectional profile, according to the joining method, according to size and, of course, according to the material from which they are made.

We will try to give you this information now, and also bring to your attention the video in this article.

Types of classification

Dimensions

Note. The dimensions can also be attributed, and the cross-sectional profile. It can be not only round, but also oval, rectangular, square and even triangular or rhomboid.

- The most basic geometrical parameter for a water pipe is the internal diameter, which determines the throughput and, consequently, the intensity of transporting the fluid. The external diameter depends on the wall thickness and this directly affects the ability of the communication to withstand a particular pressure from the inside or outside, in addition, the temperature of the transported fluid may depend on this parameter.

- But in most cases, if you ask about which pipes to choose for the water supply, you will be called Du or DN - This abbreviation means the diameter of the conditional passage and this indicator almost never (with rare exceptions) does not coincide with the internal section.

- So, for example, DN 150 or DN 150 may be at a pipe with an outer diameter of 159 mm, but in one case the wall thickness will be 8 mm, and in the other - 5 mm, that is, the internal clearance will be 143 mm and 149 mm, but conditional passage will be taken as 150 mm. Shutoff valves are classified in the same way, and everything is regulated by the norms of GOST 28338-89.

Note. The production of steel pipes is carried out with a standard outer diameter and the need for an increase in pressure is compensated by the wall thickness. Hence the difference between conditional and real passage.

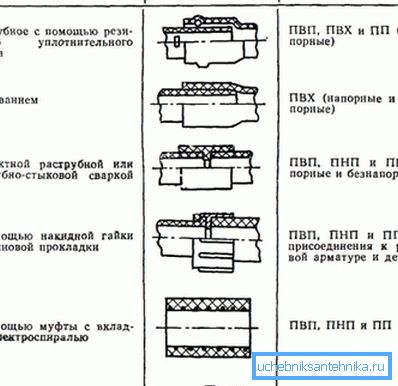

Compound

The method of joining of water pipes directly depends on the material from which these communications are made. For example, polymers are connected by heat treatment and gluing, using various couplings, clamps and adapters - here, perhaps, the widest choice.

Metals are connected using electric and gas welding, soldering, casting, as well as using nipples. Concrete, reinforced concrete and asbestos are connected by homogeneous couplings using glue and cement mortar, as well as various rubber seals.

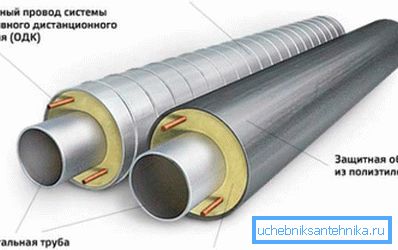

Insulation

All pipes that are used for water supply can be qualified according to the type of insulation, so they can be without it, it can be reinforced, sand-cement (concreting) and polyurethane foam.

The latter method of thermal protection can be called the most common, and, this applies not only to the Russian Federation, but to the whole world. In addition, plumbing communications can be insulated with your own hands, using foamed polyethylene, glass and basalt wool, foam plastic and extruded polyethylene foam for this purpose.

Material classification

Steel

At the moment, steel is the most common material for laying such communications, but it can be ordinary, stainless, galvanized, chrome-plated and nickel-plated water pipes. The first option is the cheapest and is also more widely distributed, perhaps because of its low cost.

But the plumbing black pipe is subject to corrosion, therefore, its operating life is much lower than that of protected communications. In addition, ferrous metals allow various organic compounds to accumulate on themselves - usually, they are algae on the inner walls, which eventually decreases the permeability.

Any anti-corrosion coating from those listed above prevents the occurrence of corrosion and reproduction of organic formations from the inside, but this significantly increases their cost.

For this reason, communications of this type are most often found in the form of an exclusive or at specialized enterprises, for example, chrome-plated pipes for plumbing can also be used as a decorative ornament - this could be a siphon for an open sink, transitions in heating, various extenders and fittings.

As we mentioned earlier, steel pipes, according to GOST 28338-89 come with a standard outer diameter, however, they are allowed deviations. So, with a cross section of up to 48 mm, this tolerance can be no more than 0.5 mm, and with a cross section of 60 mm to 114 mm, a difference of 1 mm is allowed. We also mentioned that the inner diameter depends on the thickness of the walls, therefore, in accordance with this parameter, they are divided into light, ordinary and reinforced.

Cast iron

Cast iron is made from iron with a high amount of carbon, so that it does not rust, has high strength, but at the same time it is very fragile and has a very large mass. But now a completely new type of casting has been developed - this is spherical cast iron.

In this case graphite in the form of carbon is added to the alloy, only it is mixed with magnesium and subjected to heat treatment, after which carbon takes a spherical shape, hence the name of the metal.

Such an alloy has higher strength and is not as brittle as we all used to see it. Moreover, the pipe can be produced with a zinc coating, which improves the already good anti-corrosion properties, as well as with bitumen or polymer insulation.

Copper

Copper pipes are very good for internal and external water pipelines; their technical characteristics (internal and external diameter, length, wall thickness) are regulated according to GOST 52318-2005.

Such communications are practically not affected by the adverse effects of climatic conditions (changes in humidity, temperature changes), as well as various aggressive substances (solvents, acids, petroleum products, etc.), which makes it desirable to install them in various industrial enterprises.

Copper is not afraid of rusting, therefore, such a layout will stand in the room for many years, moreover, it can be done, both as an external and as an internal version. The most important disadvantage of copper communications is the relatively high price - such water pipes are the most expensive.

Polymers

For pipes of low and high pressure, pipes based on polymer components are most often used today - they are the cheapest, convenient to install (join) and are quite cheap.

Among them are the following materials:

- PVC is polyvinyl chloride, which is also called vinylloplastic. It can be used not only for low, but also for high pressure communications.

- HDPE - low pressure polyethylene. It is often used in the private sector for tapping into a centralized water supply system, as well as for connecting hydrophores and submersible pumps in wells and a well.

- LDPE - high pressure polyethylene. Used for outdoor communications.

- PP or PPR (PPR) - polypropylene. It can be used for distributing internal communications of water supply and heating.

- PEX - crosslinked polyethylene. Such water supply pipes can be used for internal systems of water supply and heating.

- PB - polybutylene. For internal communications.

- MP - metal plast. Polypropylene with aluminum foil reinforcement. It is applied to internal systems of water supply and heating.

Conclusion

For home communications instruction allows the use of any of all the above materials. However, now most often use polyethylene, polypropylene and a little less - metal.