What diameter of the pipe to choose for heating: a

When you spend heating in an apartment or a private house, in addition to the material of the pipes used, the dimensions of their sections should also be taken into account. They determine the amount of fluid to be passed for a certain unit of time, which significantly affects the performance of the entire structure. We will discuss further how to find this indicator.

The relationship between the cross section of the pipeline and the capacity of the pressure in it

For a start, it is worthwhile to dispel the myth that the thicker the pipe, the more intense the movement of the coolant in it. With an excessive increase in diameter, the pressure in the system may drop to such an extent that the heating in the house will not become altogether. To prevent this, read the following table, which lists the parameters of the coolant for the most common types of tubular products:

| View pipe | Consumption, m3/ h | Speed, m / s | Head loss, m / 100 m |

| Steel new 133? 5 | 60 | 1.4 | 3.6 |

| Steel old 133? 5 | 60 | 1.4 | 6.84 |

| PE 100 110 × 6.6 (SDR 17) | 60 | 2.26 | 4.1 |

| PE 80 110? 8.1 (SDR 13.6) | 60 | 2.41 | 4.8 |

| Steel new 245? 6 | 400 | 2.6 | 4.3 |

| Steel old 245? 6 | 400 | 2.6 | 7 |

| PE 100 225? 13.4 (SDR 17) | 400 | 3.6 | four |

| PE 80 225? 16.6 (SDR 13.6) | 400 | 3.85 | 4.8 |

| Steel new 630? 10 | 3000 | 2.85 | 1.33 |

| Steel old 630? 10 | 3000 | 2.85 | 1.98 |

| PE 100 560? 33.2 (SDR 17) | 3000 | 4.35 | 1.96 |

| PE 80 560? 41.2 (SDR 13.6) | 3000 | 4.65 | 2.3 |

| Steel new 820? 12 | 4,000 | 2.23 | 0.6 |

| Steel old 820? 12 | 4,000 | 2.23 | 0.87 |

| PE 100 800? 47.4 (SDR 17) | 4,000 | 2.85 | 0.59 |

| PE 80 800 ± 58.8 (SDR 13.6) | 4,000 | 3 | 0,69 |

Selection features

How to choose a pipe diameter for heating? Let's take a look at the beginning with their description.

Description

The choice of the diameter of pipes for heating is determined by the following characteristics:

- The distance between the inner walls - the internal diameter of the pipe. This is the most important indicator showing the throughput of the future design.

- The distance between the outer walls - outer diameter. It is classified into:

| Class | Parameter, cm |

| Small | 0.5-10.2 |

| Average | 10.2-40.6 |

| Big | 40.6 or more |

- Conditional pass. The section value is rounded and converted to inch units.

The difference between the external and internal diameters is the wall thickness of the product, which affects the heat transfer of the pipeline.

Less or more

After the calculations, the values may take a certain range, in which direction it is better to deviate: to a larger or smaller one?

Experts believe that it is more rational to use a small section for several reasons:

- In the pipeline there is a smaller amount of coolant that needs to be heated. Thus, the cost of operating the heating system is reduced.

- Easier to do the installation by hand.

- Lower cost of thin tubes themselves compared to thicker samples.

Tip: you should not specifically underestimate the results of calculations, as it will significantly reduce the efficiency of the heating system and make it very noisy.

It should be borne in mind that the ideal speed is the interval between 0.3 and 0.7 m / s.

Performing calculations

In order to understand the essence of the process, consider it on the example of finding the optimal cross section for heating pipes located in a room of 20 m2.

The instruction is as follows:

- First of all, we find the indicator of the required heat transfer. If the walls have insulation, and the ceilings do not exceed three meters, then for every ten square meters, 1 kW of thermal power is required. Substitute to our version and get 2 kW.

- Next, we add the necessary twenty-percent reserve, which ultimately gives us 2.4 kW.

Tip: It is recommended to use a calculator when making online calculations. Such a program can significantly simplify the task and avoid typical errors.

- If there are windows in the room, add the same number of batteries with a capacity of at least 1.2 kW. Usually they are placed directly under the window openings.

Important: the value of power can take more, but in no case less, since your system will not cope with its task.

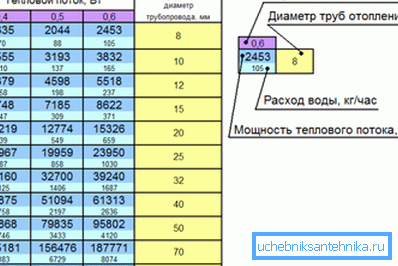

- In the table containing internal diameters, we find the obtained power value of 2400 W. There we see that pipes with eight millimeter diameter are suitable for a given heating system. The velocity of the fluid will be equal to 0.6 m / s, the flow rate - 105 kg / h and the exact thermal power - 2453 watts.

It is also permissible to use pipes with a ten millimeter diameter, then the coolant velocity will decrease to 0.4 m / s, the flow rate will increase to 110 kg / h, and the capacity will increase to 2555 W.

Conclusion

Selection of the diameter of the pipe for heating is a very important task, and the performance of the entire system depends on the correctness of this stage. Too wide products can stop performing their functions altogether, and too thin ones will work inefficiently and noisily (see also the article Outer diameter of pipes - all you need to know about dimensions).

Therefore, it is necessary to take into account all the details when making calculations and making choices in order to achieve the maximum effect. In the article we set out all the information that is needed for this.

On the presented video you can familiarize with the additional materials having a direct bearing on the considered topic. Be careful when making calculations!