What is a corrugated pipe: features of the most popular

In production, industry, construction, as well as for various domestic purposes, a corrugated pipe with two-layer broach is used, or another type of such structural hoses. Depending on the technical conditions that determine its application, the material (plastic, rubber, metal), its qualitative composition and dimensions (length, diameter) will change. We'll talk more about this below, providing more information.

Corrugated products

Note. By and large, the pipe is corrugated - GOST depends on the material - is a universal device. Here a single-layer or two-layer wall with a polymer shell and / or reinforcement elements is possible.

- For flammable structures, through which you need to stretch communications cables, as well as for the transportation of gases and liquids, a corrugated steel pipe is often used, which can be made of black or stainless steel. The configuration of the surface (the shape of the corrugations, the pitch of the rings, the diameter) can be very different, but at the same time such indicators will not affect its quality, but only indicate that they belong to one or another manufacturing plant. Products of this type are manufactured according to the All-Union standard OST 35-22-83.

- In most cases, a corrugated rubber pipe is used for pumping liquids, but it can also serve for seed-and-pipelines (using TU RB 00149438.091-99), couplings and nozzles of various sizes. Such a rubber product is often reinforced with a steel helix, which significantly increases its technical capabilities, since the stiffness made possible to withstand severe mechanical loads when working on suction or pressure. Products of this type are made according to GOST 5398-76.

- As a rule, corrugated plastic pipe can be used as a flexible cable channel for various communications, as well as sewer connections for siphons of sinks, bathtubs, sinks, shower cubicles, toilet bowls and so on.

For its manufacture, PVC (polyvinyl chloride), HDPE (low pressure polyethylene), LDPE (high pressure polyethylene) or both of these modifications are used at the same time (two layers). In addition, for sanitary purposes, it can be reinforced with steel rings or spirals. Products of this type are manufactured according to GOST 17675-87.

Review of materials

Steel

At the moment, Korean corrugated non-combustible stainless steel pipe holds the leading position on the construction market, although in the 20th century, Japanese manufacturers began to manufacture it for the first time. But if we talk about the geography of use, it covers almost the entire world. The popularity and high price of such products are not surprising, since they are made of high-alloy steel.

Considering the fact that stainless steel is not susceptible to corrosion and oxidation, such products do not require preventive maintenance, therefore, their service life is almost unlimited. This quality allows you to use stainless steel corrugation in a closed way, that is, to lay it under the cladding (drywall, wall paneling), pour it with concrete and seal it with a putty.

For such a pipe, compensating couplings are not needed, since the temperature deformation is extinguished by the structure of the product itself, and in the case of freezing it can be warmed even with an open flame. When transporting liquids on the inner walls of the various deposits are not formed and organic formations such as algae, so additional cleaning is not required here.

Sometimes these hoses have a polyethylene coating, which is more used for decoration, for example, for cold water, a blue coating is made, and for hot water - a red one.

Corrugated steel hoses are coupled to each other, as well as with various mechanisms and devices, using special brass fittings, which are also compression fittings (compression is created by rubber or paronitic gaskets that are supplied with the fittings).

There are no special tools for installation here - masters usually manage with a wrench or gas wrench, and occasionally with a wrench.

Note. Not so long ago steel hose began to be used for the installation of gas installations. Such hoses are much more reliable than rubber - they can withstand any pressure that is possible in the system, they do not burst and do not crack with time.

Rubber

Despite the fact that these hoses are called rubber, in fact, they are a multi-layer composite rubber-technical product. Pure rubber sleeves are mechanically fragile and are used except for seed and tuft lines. In everyday life, you can see a reinforced hose of this type on fire and sewage trucks (barrels).

The classification of hoses according to GOST 5398-76 is given in the table:

| Class | Where applicable | Additions |

| B | Petroleum products such as oils, diesel and jet fuel, kerosene, gasoline, kerosene, fuel oil | Can be in the usual version (B), or with anti-static B (A) |

| AT | Technical and drinking water | |

| R | For gases: nitrogen, carbon dioxide, air | |

| KSH | Weak solutions of acids and inorganic alkalis (up to 20%) | All acid and alkali resistant rubber products of this class |

| P | Weak-acid solutions of organic and inorganic compounds, alcoholic liquids of various types, technical and drinking water | When operating such hoses in cold climatic conditions, the decision is consistent with GOST 2.124. |

Note. The 1st group includes suction hoses with a negative pressure of up to 0.08 MPa, and the 2nd group includes pressure-suction with a possible pressure of up to 1.2 MPa. Different rubber hoses with a textile frame can be used in any heat (tropical climate) with a lower temperature threshold of -50? C.

When buying this type of rubber, pay attention to the presence of marking (this is the same instructions for use), which must necessarily be applied in the form of a longitudinal strip using relief or indelible paint. Symbols that you see there indicate the class, group, internal diameter, nominal pressure and the possibility of climatic use.

For example, marking B (A) - 1 - 25 - 10 - T - GOST 5398-76 indicates that the sleeve with antistatic is designed for pumping fuel with a working pressure of 1.0 MPa in a tropical climate with a lower limit of -10? C.

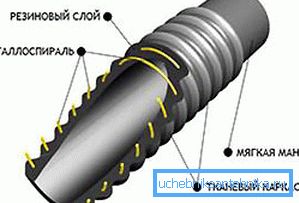

In the picture you see the construction of a multi-layered rubber sleeve, which consists of the following elements:

- Textile braid;

- Rubber layer;

- Metal spiral;

- Rubber layer;

- Textile braid;

- Extra textile or rubber layer.

For class B, P and KSH hoses, the outer layer is made of rubber, and at the ends of such sleeves there are usually frameless soft cuffs that allow connection to transition pipes and rigid pipelines. Warehouse storage of such rubber technical products should be carried out at temperatures from -25? C to +35? C, at a distance of at least one meter from heating devices of any type.

Polymers

To protect cable and wired communications in difficult operating conditions, polyamide corrugation is used, which is able to maintain flexibility and mechanical strength during impacts and at temperatures from -40? C to +105? C, and for a short period of +150? C.

When diving to a depth of 20m, unique compression accessories provide reliable sealing, as well as ease of installation. In addition, the walls of polyamide protect the cables from various petroleum products such as gasoline, diesel fuel, kerosene and oils, they are resistant to ultraviolet radiation and do not respond to vibration loads.

| Nominal section (mm) | Inner diameter (mm) | Outer diameter (mm) | Bending radius (mm) | Bay Length (m) | Code with a broach | Code without broach |

| 7 | 6.8 | 10.1 | 15 | 50 | - | PA600710F2 |

| ten | 9.7 | 13.0 | 20 | 50 | - | PA601013F2 |

| 12 | 12.2 | 15.8 | thirty | 50 | PA611216F2 | PA601216F2 |

| 17 | 16.8 | 21.2 | 40 | 50 | PA611721F2 | PA601721F2 |

| 23 | 22,6 | 28.5 | 55 | 50 | PA612329F2 | PA602329F2 |

| 29 | 28.3 | 34.5 | 65 | 25 | PA612935F2 | PA602935F2 |

| 36 | 36.3 | 42.5 | 80 | 15 | PA613643F2 | PA603643F2 |

| 48 | 47.4 | 54.5 | 95 | 15 | PA614855F2 | PA604855F2 |

Product Range

According to GOST 287-79, polyamide pipes of this type can be of two types - PV-2 and PV-0.

- First option it has higher impact resistance, and can be used for the installation of industrial equipment, television and electrical communications, communication systems, where cable requirements are not increased fire safety requirements.

- Second option has lower mechanical strength and is used for the same purposes, but with certain fire safety requirements. It is noteworthy that it is PV-0 that is used for communications of electricity and communication when they are mounted with their own hands at home.

Polyvinyl chloride pipes are made of the same material and are used as cable channels for television and radio communications, power grids and communications. Also, they are successfully used at home (the price is quite reasonable) for masking the same networks under a frame cladding such as drywall and wall paneling, but they are not poured with concrete or put up with a putty.

Tip! If there is a need to protect the hidden content from exposure to ultraviolet radiation, choose a corrugation in black.

Corrugated pipe with a probe is well suited for frame lining of the false ceiling type, which allows not only connecting cables inside the channel, but also carrying out repair work on dismantling / mounting the contents. PVC corrugation with a probe is sufficiently resistant to low and high temperatures (on average from -40? C to +40? C) and does not react to contact with petroleum products from the category of fuel and lubricants.

Very often for the installation of various cable communications corrugated double pipe made of combined polyethylene is used, that is, the layers have different characteristics.

These are HDPE (HDPE) - low pressure polyethylene and LDPE (LDPE) - high pressure polyethylene (do not confuse - the polypropylene pipe has no relation to such products!).

- The top layer consists of PND and it is easy enough to define it to the touch. It is gritty and does not have a brittleness, but it is resistant to shocks, does not react to petroleum products from the category of fuels and lubricants and is an excellent dielectric.

- Inside there is a layer of LDPE - it is most often white in color, has a very smooth surface and has good elasticity.. To all this, you can add the same positive qualities as the PND.

Note. It should also be noted that medium pressure polyethylene (PSD) is also produced, but it is often referred to as HDPE and is practically not used in the production of corrugated products.

Conclusion

Anyway, the corrugated pipe made of polyamide, polyethylene, rubber, steel, or a combination of these materials is fairly well established in our everyday life. And even if you do not notice this - in any case, you use the various benefits of civilization, where such a device is used.

In the thematic video in this article you can find additional information on the subject under discussion, it is possible that it will also be useful for you.