What is a culvert, what are the features of their operation

In any area you can find rivers, ponds, ravines and just the place of flow of spring floods. Such relief features make it very difficult to arrange roads, especially as regards the connection of settlements. There are two engineering solutions to this problem: bridges and culverts.

About the second of them will be discussed in this article.

Technical and structural features

The water pipe is a special cylindrical structure of a certain size, which is installed at the base of the roadway and is a kind of tunnel for the water flow flowing under it. That is, if there is, for example, a stream through which a high-quality road needs to be laid, the described structure is mounted in its channel, and planned works are being carried out on it.

You should know: the water transmission of the functionality of such pipes is not limited, and sometimes they are used to create livestock underpasses or other overpasses.

Comparison with the bridge

If, in essence, the main task of the product in question is to lay a road through a water obstacle, then why not install a small bridge for this?

The fact is that at approximately the same construction costs, the pipe has several advantages:

- There is no violation of the integrity of the subgrade and the structure of the paved path.

- Relatively low content of culverts. Repair and maintenance costs less than bridges.

- Reducing the load on the pipe is proportional to the increase in the thickness of the mound of soil, ranging from two meters.

- Reasonable price for the whole structure.

Thus, it can be concluded that in the case of a large distance between the banks, the bridge remains the only possible construction, but with a short distance, the installation of a culvert pipe will become much more rational.

Species

There are many types of structures under consideration, their distinctive features can be distinguished in the following table:

| Difference | Possible options |

| According to the material |

|

| According to the shape of the cross section |

|

| By the number of points in the section |

|

| By the pressure |

|

Dimensions

The recommended ratio of the diameter and length of the drain pipe look like this:

| Diameter, m | Length, m |

| one | No more than 30 |

| 0.75 | No more than 15 |

| 0.5 | No more than 10 |

There is also a definite formula for the calculation of culverts:

Ltr= in + 2 (ns-d)? m, where

| Symbol | Value |

| Ltr | The length of the whole structure |

| at | Soil web width |

| n | The thickness of the bulk layer |

| with | Wall thickness |

| d | Diameter of section |

| m | Slope rate |

General rules of arrangement

- When installing a ten-meter pipe on an on-farm road with a half-meter section, it is required to make a mound with a thickness of at least fifty centimeters.

- Culvert pipes on highways over SNiP can be located only on condition of availability of a profile and plan corresponding to this type of roads.

- The most common type of operation of these facilities - free-flow, involving the natural flow of water. Less commonly used pressure or semi-pressure.

- The instruction prohibits the installation of culvert constructions on reservoirs, along which in case of ice formation ice drifts move, as ice floes can create an emergency blockage at the entrance to the pipe.

Tip: for the arrangement of pipes in rivers where fish spawning takes place, it is first necessary to obtain permission from the fish control authority. In the opposite case, the developer will expect a large fine.

- The distance to groundwater should be respected, depending on the operating modes, the following:

| Operation mode | Distance, cm |

| Free-flow | 50 |

| Pressure head | 100 |

| Semi-head | 100 |

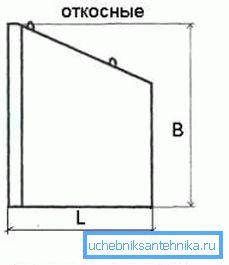

- The ends of the culvert pipes are created from the walls of the portal and sloping wings buried in the ground below the frost penetration level of 0.25 m and having a gravel pillow with a thickness of at least ten centimeters.

- Normal soil under construction is replaced by a mixture of sand and rubble. This will eliminate its sagging.

- There are three types of groups that differ in their carrying abilities. In each of them, the height of the backfill has its own indicator: 2 m, 4 m and 6 m, respectively.

You should know: in non-standard conditions it is allowed to use other ground fillings and calculated heights in order to achieve a more rational use of resources.

- Marking of culvert pipes is carried out with the help of letters and numbers separated by a hyphen. On the left side indicates the type of product, and on the right side - the diameter of conventional passes, the useful length and the numbers of groups that determine the bearing capacity of the structure.

- Concrete products are installed according to GOST 26633. For this purpose, heavy concrete with a strength class not lower than B25 and watertightness is used - W Only such parameters guarantee a long and proper operation of the structure.

You should know: the presence of cracks in pipes made of concrete and reinforced concrete is not allowed. The only exception is the shrinkage width not exceeding 0.05 mm.

- Monolithic concrete slabs of class B are suitable for creating wings. Reinforcement is not necessary.

Construction works

On the performance of work only with his own hands, speech and can not be, since the structural elements are overall and heavy. But with the installation team and the appropriate equipment will be easy to handle.

Foundation pit

When digging a pit, several rules are followed:

- Fastening of walls is provided only in case of high soil saturation with groundwater.

- The steepness of the slopes is determined according to the depth of the trench and the properties of the developed soil.

- If you plan to install waterproofing on or other similar work involving the presence of people in the pit, then its walls should be removed from the basement at a distance of not less than 0.7 m.

Tip: if no additional work is planned after laying the pipe, it can be limited to an interval of 0.1 m. This will be enough to ensure the normal installation.

- Along the perimeter of the object, soil rollers are arranged to prevent the penetration of surface water into the trench.

- In cases where the installation is carried out on the territory of the reservoir, you can use one of two ways to remove fluid from the building site:

- If the situation is on a slope, then from the bottom of the pit just an additional trench is digging to divert water into the ditch.

- In other cases, it will be necessary to create a sump and pump out fluid from it using pumping equipment.

Foundation

The most common are prefabricated and monolithic foundations, less commonly used prefabricated monolithic, and for places with weak soil is better suited columnar.

Consider the course of installation on the example of the most time-consuming option - monolithic:

- Install the formwork around the perimeter of the fill.

- Knead or deliver concrete solution.

- We make filling and ramming of the mixture.

Tip: in the process of pouring concrete, it is recommended to punch it periodically with a steel bar. This will avoid the formation of air pockets.

- Cover the concrete with a film and pour water until it sets.

- Remove the formwork.

- We cover the space between the ground and the monolith of the basement with gravel mixed with sand.

The prefabricated base is distinguished by the fact that instead of pouring mortar, ready-made concrete components are mounted.

Pipe material

Concrete or reinforced concrete pipes are classic in this matter and are time tested. But I want to pay special attention to a more advanced version, which is a metal corrugated structure.

The advantages of this type of facility:

- A wide range of different diameters. Allows you to make the most optimal choice for any situation.

- Low weight. Significantly simplifies transportation and installation work.

- Easy installation. The handling of the material in question does not require any special skills.

- High strength and flexibility. In combination with the soil gives greater reliability than the reinforced concrete structure.

- The long operational term reaching to hundred years.

- Low price. It gives up to 50% savings compared to using other materials.

- Versatility. It is applied in any climatic conditions.

Waterproofing

Waterproofing works are most often performed using bitumen mortar or sheets of roofing material. The main thing before laying the material is to clean the surface of the pipe from debris, dirt, and in winter and from glaciation.

backfilling

After the structure is installed, it should be backfilled with soil. For this purpose, the one that was previously removed from the excavation is quite suitable.

Everything happens as follows:

- Evenly we fall asleep the ground in the space between the soil and the walls of the structure.

- When the soil is filled up on both sides, we seal it with the help of special tamping machines.

- After that we create a mound on top, the thickness of which corresponds to your project.

- Directly above the pipe, the seal does not occur to avoid technical overload on the product.

Conclusion

The construction of bridges is not always justified in the construction of roads across rivers or ravines. Often it is much more rational to install a culvert, which is cheaper and has several important advantages (see also the article Crimping pipes in your home).

The key to successful installation is compliance with certain rules, which are described in detail above. The process itself consists of excavation, laying the foundation, laying the product itself and back filling it.

The video in this article will provide you with an additional amount of information directly related to the reviewed materials.

The installation of the described structures allows to solve many problems associated with the laying of roads on the terrain, rugged by rivers and ravines.