What kind of electrodes are needed for welding pipes,

There is an erroneous opinion that the quality of the weld depends only on the performer, but this is far from the case, and any good welder understands that the electrodes for welding the heating pipes and plumbing play far from the last violin in such works.

First of all, it should be noted that such conductive rods can be either metal or non-metal, that is, carbon or graphite, but in this case, the second type does not interest us.

Let's look at what signs can distinguish consumables of this type, how to pick them up better, and also the video in this article will demonstrate visual information on our topic.

How are they distinguished

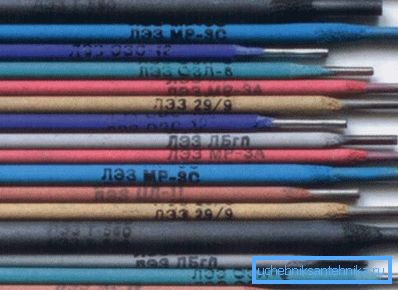

Electrodes made of metal can be melting and non-melting. The first type can be coated with steel, cast iron, bronze, copper or aluminum rods, while the uncoated ones are currently used only in the form of wire (see photo above) when welding works are performed in a gas-protective environment.

Intrinsic, thoriated, lantinated, and tungsten are non-melting species; therefore, it is quite natural that their price is much higher.

In addition, the electrodes are classified by purpose, that is, by the type of material to be processed. For high carbon steel according to GOST 9467-75, the material is marked with the letter U, for alloyed and heat-resistant steels - with the letter T, while for the fusing of the surface layer - with the letter T.

In most cases, a coating is present on the rods, but it is also different and has its own marking according to GOST 9466-75.

For example:

- thin coating is marked with the letter A (international format - A);

- medium - with letter C (international format - B);

- thick - the letter D (international format - R);

- and especially thick - the letter G (international format - C).

In addition to the thickness of the coating layer, it is classified according to its type:

- A - sour;

- B - the main;

- C - cellulose;

- R - rutile;

- P - mixed.

In addition, the mixed layer can be:

- AR - sour rutile;

- RB - rutile;

- RP - rutile-cellulose;

- RJ - rutile, with an admixture of iron powder.

Note. Due to the fact that welding can be performed in different positions, the electrodes are classified here into different types. So, they can be for the lower position of the vertical bottom-up, horizontal and lower in the boat. Also, the instruction implies rods for any position.

To destination. Types of materials

- Carbon and low alloy structural steels. In this case, the temporary tensile strength can be up to 60 kgf / mm or 600 MPa.

- High alloy steel types, which are endowed with special properties.

- Structural steel, where arc welding is applied. Here, the temporary tensile strength will already be more than 60 kgf / mm or 600 MPa.

- Surfacing of the surface layer of metal, having special properties.

- Cast iron.

- Non-ferrous metals. (See also the article Sewage in the cottage: features.)

Coverage Details

- A - acid or acidic coating. It consists of iron oxides of manganese and silicon.

- B - the main thing. It contains calcium fluoride and calcium carbonate. Welding works with the help of such electrodes are performed by direct current of alternating polarity.

- C - cellulose. It contains flour and other organic components that are intended to create a gas containment shell during welding operations.

- R - rutile. It contains rutile, as the main component, as well as other mineral and organic components. In addition to gas protection, such components can significantly reduce splashing in the production of the seam.

Note. In household use (heating, frames), everything is somewhat simpler, since there is usually used for all cases electrodes with the main (B) coating, the diameter of which depends on the thickness of the metal. For example, if you are interested in what kind of electrodes to weld a profile tube, then considering the thin wall of the profile (1.0-1.5 mm), you should use a 2 mm cross-section rod. Depending on the welding (transformer or inverter), you will select the consumables themselves (for alternating or direct current).

Consumption rates

For the installation of heating, the consumption rates of electrodes when welding pipes can be different, depending on the joining of the welded heating pipes and the type of weld, but we will consider only the vertical joint without bevel edges, as the most frequently used.

| Wall. Thickness in mm | Weight of fusing in kg | Electrodes in groups in kg | ||||

| II | III | IV | V | VI | ||

| 3 | 0.107 | 0.194 | 0.207 | 0,220 | 0.233 | 0.346 |

Electrode consumption when welding pipes per meter of weld

| Pipe dimensions in mm | Weight of fusing in kg | Electrodes in groups in kg | ||||

| II | III | IV | V | VI | ||

| 23? 3 | 0,008 | 0.014 | 0.015 | 0.016 | 0,017 | 0.015 |

| 32? 3 | 0.011 | 0,019 | 0.020 | 0.021 | 0.023 | 0.024 |

| 38? 3 | 0.012 | 0.022 | 0.024 | 0.025 | 0.027 | 0.028 |

| 45? 3 | 0.015 | 0.027 | 0.029 | 0.030 | 0.032 | 0.034 |

| 57? 3 | 0.919 | 0.034 | 0.036 | 0.039 | 0.041 | 0.043 |

Electrode consumption when welding pipes for 1 joint

Note. By and large, electrodes of any type are classified as one of the groups of welding materials. In addition to them, this includes filler rods, wires, protective gases and filler fluxes.

Conclusion

As you have noticed, there are a lot of types of electrodes, but if you want to cook the heating in the house with your own hands, then you immediately need to tilt the materials for high-alloyed and colored steels, as well as cast iron.

In addition, the thickness of the walls of heating pipes, as a rule, is not less than 2 mm, then a rod of 3 mm is needed. In addition, you can use an electrode for all positions, with an average coarsen coating (C) of the type, acidic (A) or basic (B), for carbon and low carbon steels.