What pipes to choose for underfloor heating

With the growth of tariffs for utilities, an increasing number of homeowners are thinking about replacing traditional methods of heating apartments with cheaper alternative methods of heating them. For example, the so-called “warm floors” are gaining more and more popularity.

The advantages of these technologies for heating residential spaces (in addition to direct savings on energy) include some refinement of the design of the room due to the removal of radiators that noticeably spoil its appearance.

Types of alternative heating systems

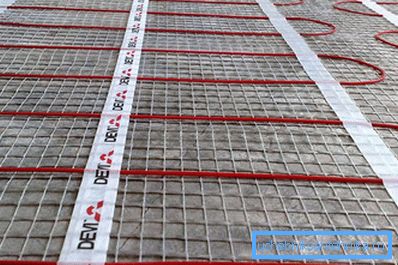

Currently, in the domestic market, two types of alternative heating systems are in great demand: electric and water ones. One of them involves the use of electric current as an energy carrier, which causes the heating of the cable, which is located under a decorative coating in the thickness of the floor. Heating can occur through the use of an infrared emitter.

According to the second method, the heating of the floor and the room as a whole is carried out through the use of an extensive network of pipelines through which hot water circulates continuously. At the same time it is important, what pipes to choose for a heat-insulated floor. Usually use copper or plastic.

Thus, the so-called water-heated floor is a system of floor pipelines, laid during installation on a concrete base or directly in the screed. Such floors provide uniform heating of the dwelling and do not need constant care. In addition, unlike electric heating systems, they are much cheaper to operate.

The disadvantages of this class of systems include the significant cost of installation and the increase in the total thickness of the floor covering.

Taking into account the fact that the proposed installation of the heating circuit will be done by own hands and that electricity is becoming more expensive all the time, the choice of a water floor arrangement looks quite reasonable. Note also that the system we are considering is ideal for heating out-of-town houses that are usually not connected to central heating.

Selection of tube blanks

Before starting work on the independent arrangement of a warm water floor, it is imperative that you decide for yourself the following technical issues:

- What type of pipe for underfloor heating is the most suitable option.

- What should be the diameter of your choice of pipe products.

- How should be distributed thread laid during installation of the pipeline on the surface of the base floor.

Answers to all these questions you can get in the subsequent sections of this article.

The choice of pipe material

When purchasing pipelines of one type or another, the main criteria for choosing them should be such characteristics:

- strength;

- thermal conductivity;

- ease of molding;

- price.

From the point of view of materials used in the manufacture of pipes, these can be:

- copper pipe products;

- pipe billets of cross-linked polyethylene;

- polypropylene and metal-plastic pipes.

In terms of thermal conductivity, the most suitable option is, of course, copper, which has good plasticity indices, allowing you to bend pipes of the desired radius. But at the same time, the high cost of copper pipelines completely eliminates all the advantages of “warm floors”, in terms of the estimated savings on heating.

According to its performance, pipes made of polypropylene (cross-linked polyethylene) could be considered an ideal option for arranging a warm water floor if it were not for their one drawback. This disadvantage is expressed in that polypropylene products have strict limitations on the allowable bend radius, which can not be less than 8 diameters. Such requirements dramatically reduce the possibilities for the effective placement of threads of the installed water pipe on the floor surface.

Taking into account all the above, the most suitable option for a water-heated floor is modern metal-plastic pipes. With a relatively low price, these products are quite reliable in operation and are easily bent. Such properties of metal-plastic products are explained by the presence of an aluminum layer in their structure, which significantly increases the thermal conductivity of the channel and ensures the preservation of shape after bending.

Tip! When using a metal-plastic pipe, in order to prevent leakage, it is necessary to avoid connecting its ends in the thickness of the screed.

Diameter selection

Once you have decided on the material, you will need to choose pipes of exactly the diameter that would provide you with optimal heating conditions. This parameter of the system is determined by the size of the heated room, as well as the pressure and temperature of the coolant circulating in it. As a rule, its value is selected within 16? 25 mm.

Tip! With an increase in the diameter of pipes, the permissible pressure in them also increases.

The most reliable and proven method for selecting the diameter of pipes is to seek help from specialists who will also help you in solving all other issues related to the choice of pipe products for floor heating systems.

Pipeline layouts

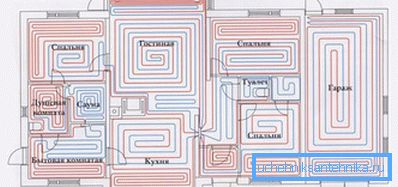

Taking into account the data obtained, you can proceed to the drawing up of a small plan-sketch, which should indicate the order of placement of water supply channels on the floor surface. The presence of such a scheme creates the conditions for competent laying of the conduit lines within the heated room, and also allows you to calculate the total number of tubular blanks necessary for arranging the “warm floor”.

A sketch or layout of the conduits within the room is prepared as follows:

- First, a plan of the room is drawn on a sheet of graph paper at the scale of your choice.

- Then on the plan is applied furniture furnishings of the apartment and areas with non-movable furniture are allocated. In these areas, to mount the conduits is not only meaningless, but also contraindicated.

- And finally, a drawing of the laying of water lines is applied to the sketch.

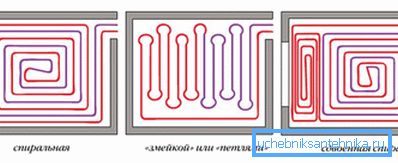

It is believed that for laying the threads of the heating conduit is best to use one of the following schemes:

- the so-called "snake", which is considered the easiest and most convenient for laying method. The disadvantage of the "snake" is the uneven heating of the room, associated with the cooling of the coolant as it moves along the pipeline;

- laying of pipes "in a spiral" provides a more uniform heating, as the coolant during circulation moves from the tie-in to the center of the room, and then in the opposite direction. With such a gasket, the number of sharp bends of the conduit is minimized, which ensures unimpeded movement of the carrier and increases its circulation rate.

In accordance with the requirements of standards, no more than 100 linear meters of pipes should fall on one heating chain, so that in rooms with a large area it will be necessary to provide for two or even three such circuits.

Note also that, depending on the installation scheme you choose and the diameter of the pipes, the chosen installation step of the conduits can vary from 15 to 30 cm.

Video

This video shows a spiral installation of a water floor.