What pvc glue for pipes used during installation

Metal pipes for cold and hot water supply, sewage and heating have a certain period of use, after which corrosion completely disables them. Recently, they have been replaced by other materials, in particular polypropylene, which has a much longer service life in an aggressive environment. In this article we will look at a method that helps to interconnect the elements of the pipeline.

How to connect PVC pipes

One of the most well-known methods is welding with a special apparatus, working from the electrical network and having a set of nozzles of different diameters for welding the products together. So often produce a compound of polypropylene products used in the laying of water supply and heating systems, at least - sewage due to the large diameter of the latter.

The equipment is freely sold in hardware stores, it can also be rented. But today we will talk about another method, which, although not as common, but has the right to exist - it is gluing PVC pipes or “cold welding”, as experts call it. Below will be considered in detail how to choose the right glue to ensure a reliable connection of the pipeline elements among themselves.

Tip: although the strength of the compound with an adhesive method is comparable to welding, the method is best applied to a cold water system.

Adhesive material

Polypropylene pipe glue consists of polyvinyl chloride dissolved in tetrahydrofuran, cyclohexanone and methyl ethyl ketone. Also in such two-component compositions add various additives that can increase the efficiency of adhesion and allow you to control the viscosity of the mixture and the time of its setting.

At the moment of hardening of the adhesive mass, the solvent begins to evaporate and the chains of polymer molecules of polyvinyl chloride, which are present in the parts to be glued, join together. Due to this, it is possible to obtain a compound having the same properties as a solid PVC pipe.

Tip: if you do not want to experience problems while working with adhesives, purchase products from trusted well-known companies, for example, Tangit or Griffon, although their price is higher than similar ones. In this case, if you follow the instructions given by the manufacturer, you will get the desired result.

What to look for when choosing

The data on the packaging adhesive mixture - information that should be considered when buying it. Get acquainted with the following parameters of the composition - its properties and setting time of the finished product.

For example, glue for plastic water pipes at room temperature hardens in 4 minutes, but if you increase the temperature to 40 ° C - then faster than 1 minute.

Also on the package there are other important information about the mixture, which should not be ignored, in particular:

- density;

- Colour;

- viscosity;

- flash point;

- storage conditions for unused substance.

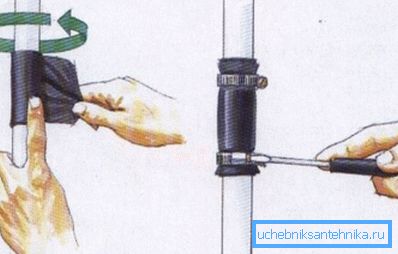

The process of preparation and bonding

Below is a detailed instruction that will allow you to deal with all the subtleties of installing a polymer pipeline:

| Training |

|

| Gluing |

|

Tip: do not move glued pipes just about 5-15 minutes. Wait also about a day before you apply water under pressure.

Remember, glue is flammable, so store it in a place protected from open flame. While working with him you can not smoke, and you should wear gloves on your hands so that the composition does not get on the skin.

What could be causing defects?

- Non-bonded places may occur due to uneven application of the composition.. In addition, large irregularities on the surface of the connected sections also lead to partial non-glue. If you have a solid non-glue, it means that the layers of adhesive were dried out in this place.

Tip: do not forget that the creation of high-quality compounds you have about 2 minutes after applying the adhesive.

- A soft adhesive layer may occur due to the low temperature in the room or you have not given enough time to harden the composition.. In this case, there was no complete removal of the solvent from the adhesive, which is part of it.

- If there was a porous adhesive layer, it was due to air inclusions, which were formed during application or due to poor mixing of the components.. The distortion in the connection is associated with insufficient fixation of the glued elements, as well as their displacement during the period of hardening of the adhesive material.

- When the surface was not cleaned of dirt, and a special cleaner was not used, you cannot moisten them with glue..

Glue for sewer pipes

Now let's look at how to glue PVC pipes used in the installation of the sewer system.

There are several types of such compounds that should be used when connecting the respective surfaces:

- Epoxy is used when gluing polymer and metal parts of pipes.

- BF-2 - for pipes made of metal and plastic.

- 88H - rubber and rubber, metal and rubber.

The process of joining PVC pipes for sewage is as follows:

- Sand the surface joints and degrease with a compound based on methylene chloride. Also, a special glue for PVC pipes is sometimes included in the degreasing kit, with which it is possible to degrease and slightly dissolve the material for a better connection.

- Cover the prepared edges with adhesive composition and paste into each other, you have no more than 90 seconds to do this. If everything happened correctly, a roller of glue will appear at the junction.

- Smear the joint again to ensure high tightness.

- After a few hours you can use the pipe in the work.

Conclusion

In this article, the following questions were discussed in detail - how to glue polypropylene pipes, how to choose glue for this work, and also why defects can occur when joining. This is an alternative method that does not yet have such recognition as the use of welding equipment.

However, if all instructions are followed, it is no different from him. The video in this article will help you find additional information on this topic.