What should be the pressure in the pipes and what this

The search engines often drive in a request about how much pressure is in the heating pipes, but this setting is not correct, since the MPa in the system depends on which system is centralized or autonomous in your house, and here, too, these figures may differ.

For example, when applying coolant to low-rise buildings, the pressure is much less than for high-rise buildings, therefore, it will differ in the circuit itself. Let's deal with these correlations together and take a look at the additional video in this article.

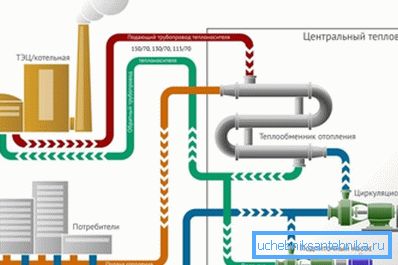

Pressure ratio

Types of pressure

Note. To calculate the pressure strength of a pipe (for an apartment contour), it is necessary to understand which types of this measurement exist at all.

- By static pressure is meant a column of water, more precisely, its height, to which its pump is able to lift from a boiler or a centralized boiler room - the calculation of power depends on this, especially for high-rise buildings.. That is, for single-storey and multi-storey buildings with the same living space, the requirements for this indicator are completely different.

- From the dynamic pressure depends on the speed of the coolant in the system - the faster the cycle is completed, the less water will cool down, therefore, the cost of its heating will be lower, and the total price of energy will also decrease.

- In addition, there is a working (constant) and pressing (maximum or test) pressure and the pipe wall thickness is calculated depending on the pressure of the pressing, and not the working. Under normal operating conditions in apartment buildings, regardless of the type of construction (new project or Khrushchevka), the operating (operating) pressure should be from 8 to 9.5 atmospheres, which is 0.8-0.96 MPa or 8.1-9 , 81 kgf / cm2), as required by the instructions. Unfortunately, in some homes this figure is greatly underestimated and is about 5-5.5 atmospheres, respectively 0.5-0.55 MPa or 5.0-5.6 kgf / cm2.

Polypropylene pipes

Note. Polypropylene pipes are usually written using the abbreviation - Russian PP or English PPR. But what pressure holds the polypropylene pipe and its thermal properties are indicated by the abbreviation PN followed by a number after it.

If we are talking about how much pressure a polypropylene pipe can withstand, it means that we are talking about the heating circuit, and, most likely, from the central boiler room, since with an autonomous system there is pressure on the circuit.

For the stand-alone option, a low-pressure polyethylene pipe is quite suitable - it is installed for a heated floor. However, in the marking of polypropylene PN10 b PN16 there is no reinforcing layer and such pipes are not suitable for the contour - PN20 and PN25 are usually used here.

Table of the dependence of the operational resource PPR on pressure and temperature

| t? C | Operating resource (years) | PPR type | |||

| PN10 | PN16 | PN20 | PN25 | ||

| Permissible load (kgf / cm3) | |||||

| 20 | ten | 13.5 | 21.7 | 27.1 | 33.9 |

| 25 | 13.2 | 21.1 | 26.4 | 33.0 | |

| 50 | 12.9 | 20.7 | 25.9 | 32.3 | |

| thirty | ten | 11.7 | 18,8 | 23.5 | 29.3 |

| 25 | 11.3 | 18.1 | 22.7 | 28.3 | |

| 50 | 11.1 | 17.7 | 22.1 | 27.7 | |

| 40 | ten | 10.1 | 16.2 | 20.3 | 25.3 |

| 25 | 9.7 | 15.6 | 19.5 | 24.3 | |

| 50 | 9.2 | 14.7 | 18.4 | 23.0 | |

| 50 | ten | 8.7 | 13.9 | 17.3 | 21.7 |

| 25 | 8.0 | 12.8 | 16.0 | 20.0 | |

| 50 | 7.3 | 11.7 | 14.7 | 16.3 | |

| 60 | ten | 7.2 | 11.5 | 14.4 | 18.0 |

| 25 | 6.1 | 9.8 | 12.3 | 15.3 | |

| 50 | 5.5 | 8.7 | 10.9 | 13.7 | |

| 70 | ten | 5.3 | 3.5 | 10.7 | 13.3 |

| 25 | 4.5 | 7.3 | 9.1 | 11.3 | |

| thirty | 4.4 | 7.0 | 9.8 | 11.0 | |

| 50 | 4.3 | 6.8 | 8.5 | 10.7 | |

| 80 | 55 | 4.3 | 6.9 | 8.7 | 10.8 |

| ten | 3.9 | 6.3 | 7.9 | 9.8 | |

| 25 | 3.7 | 5.9 | 7.5 | 9.2 | |

| 95 | one | 3.9 | 6.7 | 7,6 | 8.5 |

| five | 2.8 | 4.4 | 5.4 | 6.1 |

It should also be said that the dependence of pressure on the diameter of the pipe does not change the overall picture, since the pressure does not change with increasing cross-section, but the volume of coolant increases, which will entail additional costs for heating water.

As you can see, for centralized heating, judging by the parameters of pressure in the system, almost any PPR will do (there is still a reserve), but here you should take into account the coolant temperature, since these two parameters should be combined.

RN10 is able to withstand a constant temperature of 20? C (briefly 45? C), and the RN16 constantly holds 35? C (briefly 60? C), therefore, this option is not suitable for hot water supply or heating.

Note. Some for some reason believe that a large cross-section of the pipe allows you to better heat the room, but this is a dangerous mistake. Firstly, as mentioned above, a greater volume of water will have to be heated, secondly, the source of heating is not the circuit, but the radiator and, thirdly, the PCB conducts heat very badly.

So, what kind of pressure polypropylene pipes are designed for, we can look at the table above, and let's return to temperature indicators again. First, consider the RN20 - such a pipe is considered universal (for hot and cold water) and is designed for continuous operation without consequences at a coolant temperature up to 80? C, and convection boilers for autonomous heating operate in the mode of 60-80? C.

Not very big differences in this regard and in condensing boilers - there is a normal operating mode of 40-80? C, therefore, both modes are ideal for PPR RN20.

But not for each region there will be enough temperature 80? C for radiators and a contour, therefore, you will have to use RN25, which can be continuously operated at 95? C. In this mode, not only the autonomous boiler can work, but also the central boiler room, if there is a need, so it will be more profitable to use this particular pipe.

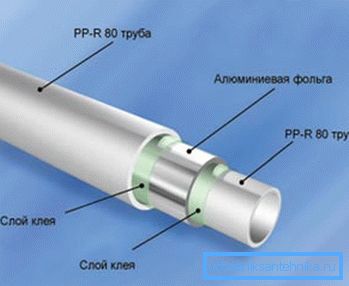

Polypropylene pipe RN25 has some features that must be considered when installing it - this is a slightly increased outer diameter and the location of the reinforcing aluminum foil is not in the middle of the wall, but closer to the surface.

If the enlarged section does not hinder much and the end still goes into the hot nozzle when soldering, then the foil will interfere, as this layer will be bare, which will reduce adhesion to the pipe connection fitting and, as a result, the quality of the joint. To avoid this, you will need to do your own to clean the end with the help of the driver, as shown in the top photo.

Recommendation. When soldering polypropylene, the end of a pipe with a diameter of 20 mm should fit into the fitting at 14-17 mm, 25 mm - at 15-19 mm. When the end goes deeper, its edges are flattened, thereby lowering the permeability or even creating a blockage.

Conclusion

In conclusion, it should be said what pressure can withstand metal-plastic pipe - it is 10kgs / cm2, therefore, it is excellent for floor heating systems. Despite the fact that polyethylene is officially used for this purpose, nevertheless, the overwhelming majority of plumbers choose their choice on metal-based laminate with a diameter of 16 mm.