What temperature can a metalplastic pipe withstand and what

In the era of wide distribution of polymeric materials, it is increasingly possible to hear the question, what temperature can plastic pipes withstand? It is quite difficult to give an unequivocal answer to it, but it is also impossible to neglect this important parameter. Therefore, we decided to devote a whole article to this aspect.

A few words about the material

First of all, our instructions will consider the material itself.

We briefly mention the main advantages of such products:

- A light weight.

- Easy installation and operation. Anyone can easily assemble and disassemble such a structure with their own hands.

Interesting: for ease of connection, you can find a variety of different fittings for pipes that can perform any, even the most complex tasks.

- Affordable price.

- Resistance to many aggressive environments (for example, corrosion).

Take for example polypropylene tube products: they are produced by polymerization of polypropylene with various metal catalysts.

Note! Temperature expansion of polypropylene pipes (the material begins to soften) occurs at 140 degrees, and melting at 180.

It would seem that this is all, because the maximum superheated steam can have a value of no more than 135 degrees. It turns out that the material described by us is suitable for use in any plumbing. In fact, not so simple.

The melting point of PVC pipes is not the only important characteristic. Another not less important characteristic is their plasticity. Simply put, at 20 degrees plastic will remain a very hard material, and at 120 it can stretch out as a result of applying even a small effort.

Thus, it can be stated that the increased pressure can also deform the system. That is why the working temperature of polypropylene pipes for most manufacturers is 95 degrees.

How dangerous is hot water in our taps?

Let's now see if hot water is dangerous in our systems.

Generally accepted standards

In SNiP 2.04.05-91 it is clearly and clearly written:

- The water temperature in the pipes of heating and other systems should not exceed 95 degrees.

- In preschool institutions, the water in the tap can not be more than 37 degrees.

It turns out that you can safely use plastic products when laying communications? The situation would be such, if not for some of the nuances.

Nuances

In almost all European countries, the transition to plastic communications. Today, this material accounts for about 80% of all communication lines in EU countries. It is quite reasonable, because in the Old World all norms are observed and it is safe to say that polymer products will withstand all the loads.

However, in our country there are two problems:

- Firstly, we still have a lot of “Stalinist” buildings in operation. In them, the heating system is not in the best condition, so power surges of heating devices are possible.

- Secondly, we live in a country with very severe winters. As a result, CHPs significantly raise the coolant capacity, launching 130 degrees of water into the system in order to maintain a normal microclimate in the houses. Recall that the maximum temperature for polypropylene pipes is 95 degrees.

Interesting: water does not turn into steam due to high pressure.

So, in such a situation, plastic products will melt and just flow down? Fortunately, this does not happen. And up to 150 degrees. But why, then, do manufacturers specify a value of 95?

The fact is that manufacturers are big reinsurers, but this is no accident. If the product becomes unusable (for example, it will burst) at a temperature of at least one degree less than the declared value, the manufacturer cannot avoid litigation.

Therefore, to the question at what temperature the pipes burst, their creators give a significantly understated answer in order to protect themselves from various troubles.

Do not forget that different batches may have different properties. Therefore, it is advisable to focus on the least quality samples.

How to protect yourself from the dire consequences

So we figured out what temperature polypropylene pipes can withstand. At the same time, we also understood that, in spite of all the norms, problems with the service life of the system may arise. To prevent an early failure of communications and even more an accident, several effective measures can be taken.

Armature will save the world

First of all, we want to advise you to use only products with reinforcement (for example, PN25). Fiberglass or aluminum foil is commonly used for reinforcement.

Such products carry a number of advantages:

- You can forget about the change in linear dimensions. It usually occurs as a result of an increase in temperature (this process is called thermal expansion). At the same time, in cases where expansion has nevertheless occurred (for example, if a serious increase in power has occurred), then deformation will not occur.

- As a result, under the same conditions, reinforced products will last significantly (by 20-30%) longer than their counterparts.

- Highways without reinforcement can burst if the temperature reaches a mark close to critical and at the same time they will be under serious pressure. Their reinforced brethren are deprived of such deplorable properties and will remain intact under any conditions.

Automation - the panacea of the 21st century

Secondly, we recommend installing a water temperature sensor in the pipe.

This device will open before you many new features, namely:

- Control over the operation of heating devices. As we have said, in the cold season, possible racing.

- Possibility of programming, depending on the weather. If you live in a region where the weather is constantly changing, then this function will be very useful for you. It allows you to set certain degrees that will be constantly maintained.

- Well, as a result of the above two factors, you will significantly increase the operational period of your communication line.

A few words about the assortment

The temperature of operation of polypropylene pipes (and any other varieties) depends on the specific brand. Of course, anyone can withstand the declared value of 95 degrees. However, unsuitable for this brand will fail in a few years (at best).

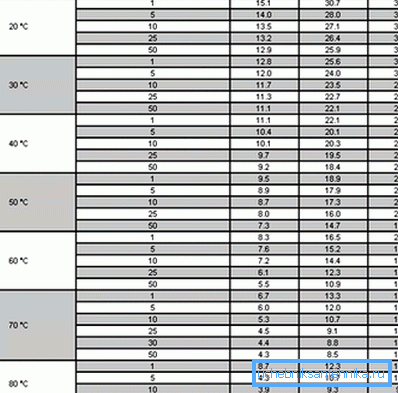

Back in 1996, SP 40-101 was developed, which regulates the service life of various brands depending on specific conditions. It allows with impressive accuracy to identify the life of the whole system.

Of course, the melting point of polypropylene pipes will remain constant regardless of the specific brand. But their lifespan will be very different.

Conclusion

This is the time to summarize our story, but we have prepared for you a visual portion of knowledge. In the presented video in this article you will find additional information on this topic. After reviewing it, you will certainly be able to understand all the intricacies.