Where and how is the 325mm tube used

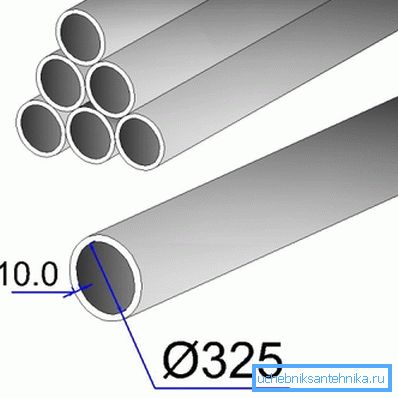

According to the manufacturing technology, steel pipe 325 can be welded or seamless with a wall thickness of 6 mm, 8 mm and 10 mm (steel grade 17G1S) - the choice of material depends on the intended internal pressure. For spiral-seam pipes, small wall thickness is characteristic, whereas for seamless pipes only a thick wall is possible (GOST 20295-85)

We will talk about some of the features of such a construction material below, and also show you the thematic video in this article.

General acquaintance

Note. Steel 325th pipes are most often used for heating, water pipes, oil and gas pipelines and can be installed underground, on the ground and by air. In addition, used material can be used as casing for concrete piles or vertical supports for drainage systems, advertising billboards, and so on.

Services for sale

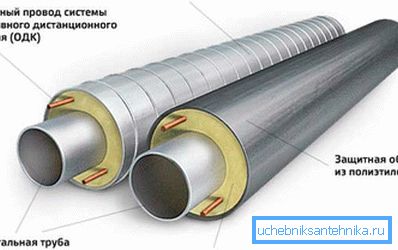

- In order to increase the service life, factories selling manufacturers offer such a service as insulation of a steel pipeline - and this not only increases the service life, but ensures safety, which is an important factor in the design, as any instruction requires.

- Cement-sand coating (CPP) can serve as an outer insulating material for tees, elbows and the entire highway.

- In addition, it can be an internal cement-sand insulation (CRI) for tees, branches and the entire pipeline as a whole can serve as a cement-sand coating.

- And, finally, a highly reinforced insulation (VUS), which consists of three layers and protects oil and gas pipelines from corrosion and mechanical damage. Of course, the price of the MAS is the highest.

- The bevel of the end part (chamfer) is achieved by cutting it by 45 ?, although it may be a different angle, depending on the ergonomic, technological or decorative purpose, and it can be both new and bu 325 pipes. The cutting process can divided into three categories, it is gas-oxygen, air-plasma and mechanical cutting.

- The most common, but also the most expensive is the mechanical method and it is carried out at pipe plants on special equipment.

- But the gas-oxygen and air-plasma method is used in the field. That is, directly at the installation site. Typically, this method is used for constructive changes in projects and lack of time. This type of work with their own hands can be performed only by a highly qualified welder.

Other characteristics

| Diameter (mm) | Wall thickness (mm) | GOST | steel grade | Length from-to (m) |

| 325 | eight | 8732-78 | 20 | 7-11 |

| 325 | ten | 8732-78 | 20 | 8-12 |

| 325 | 12 | 8732-78 | 20 | 8-12 |

| 325 | 14 | 8732-78 | 20 | 8-10 |

| 325 | sixteen | 8732-78 | 20 | 7-11 |

| 325 | 18 | 8732-78 | 20 | 7-9 |

| 325 | 20 | 8732-78 | 20 | 7-9 |

| 325 | 22 | 8732-78 | 20 | - |

| 325 | 24 | 8732-78 | 20 | 7-9 |

| 325 | 25 | 8732-78 | 20 | 7-11 |

| 325 | 26 | 8732-78 | 20 | - |

| 325 | 28 | 8732-78 | 20 | - |

| 325 | thirty | 8732-78 | 20 | 7-9 |

| 325 | 34 | 8732-78 | 20 | 6-9 |

| 325 | 35 | 8732-78 | 20 | - |

| 325 | 36 | 8732-78 | 20 | - |

| 325 | 38 | 8732-78 | 20 | 5-7 |

| 325 | 42 | 8732-78 | 20 | 5-7 |

| 325 | 45 | 8732-78 | 20 | 5-6 |

| 325 | 48 | 8732-78 | 20 | 6-7 |

| 325 | 50 | 8732-78 | 20 | 5-7 |

Hot-rolled seamless pipe

Note. In order to determine the weight of a pipe 325x6 or the weight of a pipe 325x8 (and others), you need to multiply the mass of one running meter by its length.

| Wall thickness (mm) | 6 | 7 | eight | 9 | ten | 12 |

| The mass of the running meter of the 325th pipe | 47.2 | 54.9 | 62,54 | 70.14 | 77.68 | 92.63 |

| Number of meters per ton of material | 21.19 | 18.25 | 15.99 | 14.26 | 12.87 | 10.8 |

Mass table per meter

Note. Another weight of the pipe 325-8 mm will depend on whether it is a new instance, restored or old. The difference is of course insignificant and does not affect the technical conditions, but, nevertheless, it is.

Cold rolling

Cold rolling of pipes is carried out on a unique mill of pilger type KPTR 350-8 - this is for seamless cold-rolled products with an outer diameter from 140 mm to 325 mm. For production, stainless, carbon and alloyed steel is used with a certain tensile strength of 1000 MPa, measured in the cold state of the metal (find out here how the pipes are painted).

It is quite natural that products rolled on a precision mill have extremely precise geometrical parameters and the same wall thickness, in addition, this also applies to the quality of the alloy.

The manufacture of pipes on precision machines allows the use of such products not only for the transportation of various liquids and gas, but also in the chemical industry, shipbuilding and even for aviation and space technology. HLTR 350-8 has a face load of blanks that are fed to the deformation zone with an edge stop, the drive is located in front, with right or left-hand execution.

The overall composition of the equipment for rolling includes a whole range of machines responsible for the operational process. These include a working three-roll stand and a drive for its movement, equipment for the feed section by lever switching, an intermediate and front cartridge, one table for loading and another for receiving finished products, devices for collecting and feeding lubricant oil, and a device for protection.

For round tubes and high quality production, a three-roll stand is needed, which lowers the varnished surface of the workpiece at the exit. Such a device consists of a power movable frame, which is designed for rolling force and its calibration, as well as of a movable cassette on which work rolls are placed.

Lubricating coolant (coolant) is fed into the deformation zone from the nozzles on the sprayers, which are located on both sides of the cage.

The feed mechanism is designed for pulsed movement of the pipe during the passage of the cassette during the opening of the rolls. The pulsed feed of the processed material, as well as the removal of the cartridge is carried out using a servo drive, where the operating mode is set by the electrical control system.

| No. p / p | Value | unit of measurement | Options |

| one | Maximum outer diameter of the workpiece with plus tolerances, not more than | mm | 360 |

| 2 | Workpiece thickness | mm | 5-40 |

| 3 | Workpiece length | m | 2.5-8 |

| four | Tolerance of the outer diameter of the workpiece | mm | ± 1.0 |

| five | The tolerance of the wall thickness of the workpiece, not more | % | ± 12.5 |

| 6 | Bulge billet | mm / m | 2 |

| 7 | Outer diameter of the finished pipe | mm | 140-325 |

| eight | Finished pipe wall thickness | mm | 3-32 |

| 9 | Maximum length of finished pipe | m | 25 |

| ten | Surface finish Ra finished pipe | um | 0.8 |

| eleven | The tolerance of the wall thickness of the finished pipe when reducing the wall thickness of at least 50%, not more | % | ± 6.0 |

| 12 | The tolerance of the outer diameter of the finished pipe | mm | ± 0.7 |

| % | ± 0.2-0.3 | ||

| 13 | Power Stroke Length | mm | 1600-1700 |

| The length of the working cassette | 1100 | ||

| 14 | Rolling caliber working area | mm | 950 |

| 15 | Maximum crate speed | two run / min | 45 |

| 15.1 | Crate operating speed | two run / min | thirty |

| sixteen | Feed rate | mm | 2-25 |

| 17 | Number of feeds per cycle | 2 | |

| 18 | Angle of rotation, no more | ° | 35 |

Technical characteristics of cold rolled

Conclusion

In conclusion, we can only say that we gave only the general characteristics of the 325th pipes and briefly, in general terms, told only about the cold rolling method, as one of the most precise ones. But you can always choose a material made by another method, if you do not need high accuracy (see also the article Non-pressure pipes - we study all types and their features).