Where is used steel tube 40x20 mm in the household

At present, in the construction of residential buildings and the accomplishment of works on the improvement of the local area, instead of wooden beams, edged boards and planed timber, products from black steel metal of various sections and lengths are increasingly used.

Metal products have high strength, reliability and durability, and a small proportion of the profile pipe 40x20x2 is quite comparable with the weight of a wooden beam, which has equivalent bearing characteristics.

General description of steel tubes

In order to evaluate the advantages of using profile metal in individual residential construction, this article will discuss the main aspects of the production and use of rectangular steel sections.

Also here will be presented a brief instruction, which provides examples of the use of such products for the construction of the house and the implementation of various works on the plot

Specifications

In order to objectively judge the possibility of applying in each particular case, one or another type of material, first of all you need to familiarize yourself with its technical characteristics.

Industrial production of this type of products is governed by GOST 13663-86 “Steel profile pipes. Technical requirements ”, therefore all manufactured products must comply with the requirements of regulatory documents.

- The entire range of profile metal, including the 40x20x2 profile pipe, depending on the purpose, is made of structural steel grades St1sp, St1ps, St1kp, St2sp, St2ps, St2kp, St3sp, St3ps, St3kp, St4ps, St4ps, St4ps, St3ps, St3ks, St3sp, St3ps, St3kp, St4ps, St4ps, St4sp, St4ps, St2ks, St3ps, St3ps, St3ks, St4ps, St4ps, St4ps, St4ps, St3ps, St3ps, St3ps, St3ps, St3ks, St3ps, St3ps, St3ps, Styles marks 09Г2, 09Г2С, 10ХСНД.

- The maximum length of commercial product samples is 12.7 m for hot-rolled and 11.7 m for cold-rolled pipes. In retail, products often come in lengths of 6 m, 3 m and 2 m.

- The dimensions of the square cross-sectional profile can be from 10x10 mm to 200x200 mm with a gradation of 5-10 mm.

- The dimensions of a rectangular profile can vary within the same range, however, the width value is greater than the height value by a gradation value of 10 mm, for example, 20x10 mm, 60x30 mm or 80x40 mm.

- The thickness of the outer wall can be in the range from 1 to 10 mm, with a gradation from 0.1 to 0.5 mm.

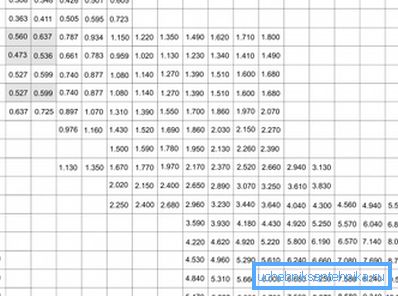

- The specific weight of one running meter of a product depends on the size of the cross section of the profile and the thickness of the outdoor machine, therefore special tables are used to calculate it. For example, based on the data in the table, the weight of 1 m of a 40x20x2 shaped pipe is 1.7 kg.

Tip! The general technical characteristics for all samples of the black rolled metal product range are approximately the same, therefore, further, as an example, a 20x40 mm profile pipe with a wall thickness of 1 to 2.5 mm will be considered.

Manufacturing technology

Industrial production of ferrous metal-rolling involves the use of various technological processes, which allow to obtain two types of fundamentally different products - seamless and electric-welded pipes.

- Seamless pipes are made by grinding the finished product from a calibrated metal billet on special metal-cutting equipment.. The final price of such products is much higher, but due to the lack of a weld, it has a higher performance.

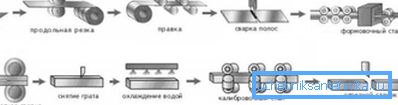

- Electrowelded pipes are made by rolling a flat sheet into a round pipe, the joint of which is hermetically sealed using high-frequency electric welding.. After that, the workpiece is sent to the calibration machine, which gives it a certain profile of the desired cross section. This technology allows a more rational use of the material, so the cost of electric-welded pipes is significantly lower than seamless ones.

Note! In a calibration machine, metal blanks are heat treated and, depending on the thermal conditions, all electric-welded pipes are divided into hot-rolled and cold-rolled. Cold-rolled pipes have the best performance, but they are more expensive, so to find out how much a 40-by-20 profile pipe costs, you need to clarify what technology it is made of.

Distinctive qualities

Profile products made of ferrous metal have high strength and ability to withstand various loads, and in addition have some advantages over round pipes.

- The significantly lower metal consumption allows a more rational use of the material with an equivalent strength and rigidity of the entire metal structure.

- Metal profile pipe 40 20, thanks to a rectangular section, allows for a more dense packing during storage and transportation of products, which leads to significant savings in storage space.

- Vertical side walls, with proper design, perform the function of stiffeners in the finished metal structure, which ensures its high strength with a small metal consumption.

- Smooth and flat surfaces tightly mate with each other, which allows for a uniform and durable weld joint.

- A small specific weight of 1 meter of a 20x40 shaped pipe with sufficient rigidity allows the manufacture of lightweight, but at the same time durable structures designed to withstand a significant load.

The main disadvantage of all ferrous metal products is its poor resistance to moisture, which leads to the formation of corrosion, and further to the complete destruction of the metal. For this reason, when working with black metal, it is important to ensure timely and effective anti-corrosion treatment of parts.

Tip! The most effective method of dealing with the corrosion of ferrous metal is to coat the steel surface with a thin layer of molten zinc using the hot-dip galvanizing method.

Application features

Taking into account the small specific weight of the meter of the profiled pipe 20x40 mm, ease of machining and good performance, it is this size range of steel metal that is most widely used in the household.

- Steel trout pipe 40x20 mm can be used for the manufacture of prefabricated metal frames in the construction of small architectural forms, such as gazebos, greenhouses or utility rooms.

- This size of the cross section is most suitable for the manufacture of longitudinal lags when installing the fence on the dacha.

- Due to its low weight and stable geometric dimensions, it can be used as a rule when doing plastering works or pouring a concrete floor screed with your own hands while building a house.

- A good ratio of strength and low weight makes it the most suitable material for the manufacture of home and garden furniture, as well as equipment for the household unit.

Conclusion

After reading this article, it becomes clear that metal profile pipes of rectangular cross section are indispensable material for building and housekeeping. To get additional information on the subject of interest, you can watch the video in this article or read similar materials on our website.