Which is better to use chimneys in the construction of

During the construction of stoves and fireplaces, as well as the installation of an autonomous heating system for a private residential house, many homeowners have a question of choosing the most suitable project for the manufacture of chimneys and smoke ducts. As is known, industrial chimneys most often represent a self-supporting structure, manufactured according to a separate technical project and having its own technological infrastructure.

At the same time, for safe and cost-effective discharge of waste gases from the autonomous heating system of a private residential building, it is most advisable to use built-in smoke ducts or front gas exhaust pipes designed in accordance with fire safety regulations.

Overview of various types of chimneys

In order to give a detailed answer to all the questions of interest on this subject, in the present article the main aspects concerning the competent choice of material for the manufacture of chimneys will be described.

In addition, the reader will be offered detailed instructions, which consider the main technological issues regarding the proper installation and placement of the exhaust system on the roof or facade of the building.

Physics and gas dynamics of the chimney

In order to understand all the features of the design and installation of chimneys, first of all you need to understand what physical processes occur in the smoke exhaust system during operation of household heating appliances.

- Normal natural chimney draft, necessary for the efficient operation of all furnaces, heating boilers, and domestic fireplaces, arises due to the difference in air pressure between the inlet of the heater and the outlet of the external chimney. As a result of the pressure difference, a vacuum of air is formed in the pipe, which helps to remove the products of combustion of fuel from the furnace to the surrounding atmosphere.

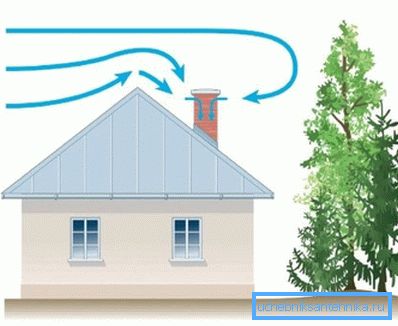

- Reverse traction, as a rule, is a short-term, but very dangerous and harmful phenomenon, which most often occurs when an illiterate design of the chimney system or the wrong location of the outlet with respect to the roof of the building occurs..

- A significant temperature difference occurs due to the gradual cooling of the heated gases in the flue, as the distance from the heating chamber of the heater and approaching the outlet. This moment is especially important to consider in heating systems with a large length of the smoke channel.

- Increased air humidity, especially in the upper sections of the chimney, occurs due to condensation of water vapor., contained in the exhaust gases, as they cool when passing through pipes and channels.

- As a result of the interaction of volatile products of combustion of fuel with water condensate, the formation of acids, alkalis and other aggressive compounds, which over time can lead to the gradual destruction of the walls of the smoke channel.

Tip! To reduce the temperature drop, and thereby minimize the formation of condensate, it is necessary to carry out a thorough insulation of the smoke channel throughout its length, using fire-resistant insulation materials.

Material selection

When choosing a material for the manufacture of chimneys, it is necessary to take into account the fact that it must have high mechanical strength and good bearing capacity in order to withstand the weight and wind loads. In addition, it must be resistant to water, acids, alkalis and other corrosive environments, and not degrade under the influence of low and high temperatures.

Currently, mass production of chimneys most often offers products from the following types of materials:

- Brickwork from solid or hollow bricks, as well as monolithic structures of reinforced concrete light and heavy brands.

- Ceramic pipe from purified from impurities, baked clay, coated on the inside and outside with a layer of fire-resistant, acid-resistant glaze.

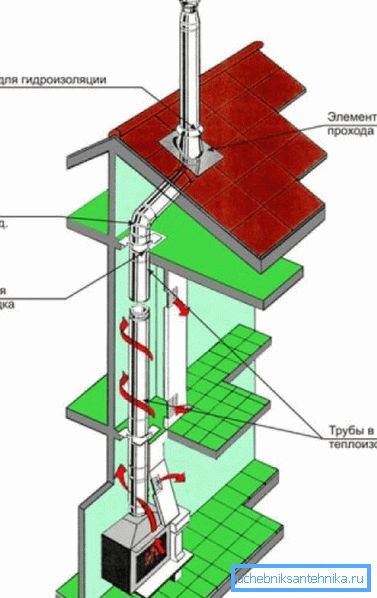

- The warmed metal chimney from the polished stainless steel consisting of two layers of metal between which fire-resistant heat-insulating material is laid.

All structural elements of the smoke channel are interconnected by means of kiln cement mortar or special refractory and acid-resistant mastic, which, after drying, remains plastic, due to which it does not collapse under the influence of temperature drops.

Shape and height of chimneys

When designing and building chimneys with your own hands, it should be remembered that the gas-dynamic characteristics of a chimney depend largely on the size, shape and height difference of the entire heating system, therefore, for its normal functioning, the following conditions must be observed:

- The least resistance to the movement of an ascending air flow occurs in a circular pipe, since such a shape best contributes to the rectilinear laminar movement of gases without the formation of turbulent vortices.

- If it is necessary to manufacture a rectangular pipe, the ratio of the length of the sides should be 1: 1.5, and it is recommended that the inner corners be rounded off as much as possible with cement mortar.

- The cross-sectional area should be at least 10 cm ?, while the diameter of the round pipe should be at least 150 mm for stoves and 180 mm for fireplaces.

- The quality of the natural traction in the furnace depends largely on the height difference, so the chimney in a private house must have a height of at least 4 m for one furnace, and at least 5 m for two furnaces.

Tip! To ensure good traction and to minimize the formation of soot in the pipe, for the manufacture of smoke channels, you should use materials with a smooth, and best of all, a mirror-like inner surface. Due to these qualities, stainless steel chimneys are the most demanded material, and although their price remains quite high, they are now widely used in individual residential construction.

Choice of location

The quality of the furnace heating system, among other things, also depends on the correct location of the smoke channels inside and outside the building, as well as on the correct choice of the point of their exit to the roof surface.

To avoid the occurrence of reverse thrust, to minimize the likelihood of condensation and prevent the destruction of the structure under the influence of external factors, it is necessary to follow simple safety rules for chimneys, which are as follows:

- Several chimneys in the same building should be combined into one group and closed with a common protective casing made of heat-insulating material. Thus, being in a common insulated casing, each of them will warm the rest, giving them some of their heat.

- The outer surface of the insulated pipe should be located no closer than 100 mm from the wooden structures of the building, and a gasket made of non-combustible insulation material, such as mineral wool or asbestos, should be installed between them.

- Separate self-supporting truss chimneys should be installed so that air pressure from the nearest buildings is not created, taking into account the prevailing wind direction for this region

- The outlet of the smoke channel should be located as close as possible to the ridge of the roof. At the same time, the heat transfer from the pipe to the atmosphere is reduced, and the free circulation of air flows necessary for creating natural thrust is ensured.

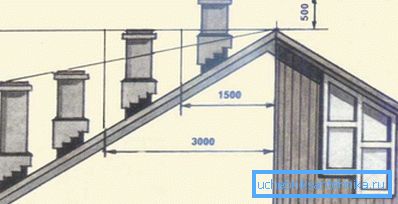

- On the roof of fire-resistant materials (slate, metal tile) the outlet should be not less than 500 mm above the ridge of the roof, and on the roof of roofing material or flexible tile this distance should be at least 800 mm.

A visual representation of the correct location of the outlet of the pipe can be obtained by looking at the figure below.

Building codes of fire safety

The design and construction of the gas exhaust ducts for household heating appliances and decorative fireplaces should be carried out in strict accordance with fire safety regulations, as well as building codes and regulations.

- Each chimney must be installed on its own foundation or have a separate mounting with special brackets to the supporting structures of the building.

- It is prohibited to use pipes as bearing supports for fixing other structural elements of the building and installation of engineering communications.

- Bearing metal structures of chimneys located on the facade of the building should be securely fastened to the wall using expansion bolts using Grover spring washers and lock nuts.

- It is forbidden to use the pipe on the roof of the building for tying cargo and securing the safety trim during roofing works.

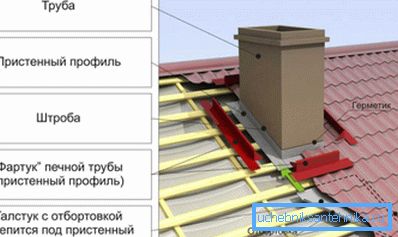

- Pairing the pipe structure with the building’s blood should be equipped with an apron made of galvanized sheet iron to protect it from rain and other precipitation.

- When the building is located on the territory of air approaches of airports, heliports or flying clubs, light fencing of chimneys is necessarily performed with the help of top signal lights, in accordance with the Manual on the aerodrome service in civil aviation (GA-86 US).

Tip! When installing a furnace heating system in wooden buildings, it is imperative to install flame-cutters and spark arresters on chimneys to avoid wood burning from the products of combustion of the combustion gases that accidentally spill out of the chimney.

Conclusion

After reading this article, you can conclude that the self-installation of a chimney in the heating system of a residential house is a very important undertaking, so before doing this work it is recommended to study in detail the fire safety rules, chimney building codes and other technical documentation.

Also, for more information, you can watch the video in this article or read similar materials on our website.