Which is better to use pipes for the fence on a country site

Currently, the construction of external fencing around the perimeter of private land ownership is a priority for any owner of their own land. As a support element for these purposes, most often new or used pipes are used for the fence, and as horizontal lags, wooden beams or steel rolled metal are used.

The choice of material for enclosing structures

In order to understand which materials are best used for the installation of the supporting structures of the fence on their own site, this article will present the comparative characteristics of various types of pipes that, by their parameters, are suitable for performing such work.

Also here will be presented a brief instruction, which describes the main technological features of the assembly and installation of enclosing structures.

Asbestos-cement pipes

Installation of the fence around the perimeter of the fenced area begins with the installation of support pillars, which are the bearing structural elements that take over the entire main load from the building envelope. The ideal option for vertical supports are reinforced concrete columns, but if they are not available, round asbestos-cement pipes of suitable diameter will be suitable for these purposes.

The main distinctive features of asbestos-cement pipes are manifested in the following qualities of this material:

- Lower specific weight and relatively low price, in comparison with similar products from metal, do them by the most demanded material for production of basic columns.

- Asbtsement is absolutely not afraid of water, it is not affected by ultraviolet radiation and tolerates significant temperature drops, therefore it can be used all year round in any climatic conditions.

- Asbestos cement bearing posts are not subject to atmospheric or soil corrosion., therefore, they do not require additional protection during the entire service life.

- Due to the high strength of the material, such pipes for fence posts maintain a long static load well and do not change their geometrical parameters during operation..

It should be remembered that asbestos cement, despite its high strength, has a low modulus of elasticity and low specific viscosity, therefore it is afraid of sharp blows and the effects of variable dynamic loads.

Tip! For installation of light enclosing structures with low wind resistance (small wooden shtaketnik or chain-link mesh), you can use polyethylene water pipes with a diameter of 80-150 mm with horizontal lags of wooden beams.

Round metal pipes

Some garden owners, who have the opportunity to get old, but still usable, water pipes for the fence, successfully use them for installation as bearing pillars.

Among the main advantages of such fences are the following distinctive features:

- The high static and dynamic strength of the support pillars provides good resistance against significant wind loads in the case of installing a high fence made of profiled sheets, flat slate or other sheet materials.

- Simple machining and the ability to use electric welding greatly facilitate the installation of horizontal lags and mounting fencing elements of the structure.

- Used metal plumbing pipes in most cases can be purchased no more than the cost of weight scrap metal.

- With high-quality anti-corrosion protection and timely proper care, steel b at the fence posts can serve more than one decade.

Steel Profile Pipes

The most suitable material for supporting pillars of enclosing structures, in terms of geometry and the impact of dynamic and static loads, is a metal shaped tube for the fence with a cross section of 80x40 mm and a wall thickness of 2 to 4 mm.

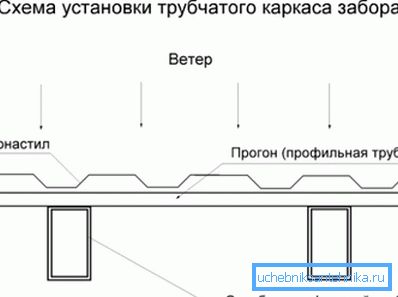

This should take into account the fact that in the case of installation of a continuous fence from sheet material, the wind load will have the greatest component of the dynamic load, the action of which is directed perpendicular to the location of the enclosing canvas. For this reason, the support columns of rectangular cross-section should be placed with the short side of the pipe parallel to the fence (see photo below).

Horizontal bearing lags, to which the fence of the fence is attached, can be made of wooden beams, but it is better to use metal profiled pipes with a section of 40x20 mm or 60x30 mm with a wall thickness from 1.5 to 3 mm for this purpose, depending on the length span.

Features of the installation work

Different types of fences can have many different structural differences, however, the installation of support pillars and the installation of the main elements of enclosing structures with their own hands, as a rule, is performed according to the same principle.

- Using wooden stakes driven into the ground, and a tightly stretched building cord, mark the land around the outer borders of your own site.

- Along the tensioned cord, around the perimeter from the inner side of the site, drill holes in the ground with a depth of 600-1200 mm with a garden drill with a diameter of 300-400 mm.

- Soil the soil at the bottom of the holes and pour in a sand pad at least 100 mm thick.

- Alternately install vertical support columns in each hole, then fill the pit to the ground level with a thick concrete solution.

- When installing the pillars, it is necessary to control their strictly vertical position in two planes with the help of a building level and a plumb line.

- After hardening of the concrete, to all vertical supports with the help of welding or bolting, attach longitudinal bearing lags on which to fix the fence of the fence. (See also the article Frame made of pipes: features.)

Tip! At each vertical support pole, regardless of the material from which it is made, you need to install a sealed plastic or metal cap to protect against water from entering the support. Otherwise, in case of frost, the water will freeze and tear the walls of the hollow pillar.

Conclusion

After reading this article, it becomes clear that not only new building materials, but also used thick-walled water pipes will be suitable for self-fabricating the fence on their own site. In order to obtain additional information on the subject of interest, you can video in this article or read similar materials on this subject on our website.