Which metal pipes are better: understand the quality

The question of how to choose metal pipes, ensuring maximum reliability and quality of communications, is very relevant. There are a lot of models from various manufacturers on the market today, and the rule “you want better - buy more expensive” does not always work.

That is why you should carefully examine all the available information about this type of material, and highlight the criteria that will be key for you.

Design features

In order to assess the reliability of metal-plastic pipes, their potential durability, and the extent to which the chosen variety will be suitable for solving the set tasks, it is necessary to thoroughly study the design features of this material.

As the name implies, pipes consist of metal and plastic parts:

- The inner and outer layers are made of polymer, and some brands use different plastics: on the outside - more dense and resistant to mechanical damage, on the inside - characterized by greater chemical inertness.

- An aluminum foil sleeve is laid between the plastic layers. The technical characteristics of metal-plastic pipes are largely determined by the thickness of this layer: the most reliable ones are equipped with reinforcement up to 0.75 mm, which allows them to withstand a very high pressure and sudden temperature drops.

Note! All products must withstand a pressing pressure of 10 bar. The maximum pressure at which the integrity of the pipe is broken is 95-96 bar (the temperature of the contents is up to 200WITH).

- Another important component of the design is the adhesive layer. It is presented in the form of adhesive mass, which connects the plastic and metal parts. The better the glue used, the longer the pipe will last without signs of wear and damage.

Main settings

Polymer used

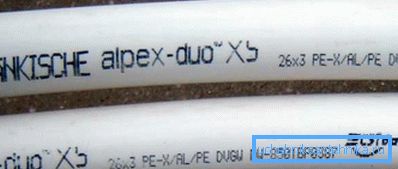

Choosing a product, the first thing you should pay attention to is the plastic used to make the pipe. Most often, marking is applied to the surface of the outer layer, so this parameter is the easiest to deal with.

What could be the options?

- The best choice is to buy a pipe made of cross-linked or linear polyethylene (denoted by PEX or PE-RT indexes). These polymers are characterized by increased heat resistance, considerable mechanical strength, as well as a perfectly smooth surface, practically not subject to wear.

Note! You always have to pay for quality, because the price of products made from such materials is usually higher than that of less durable modifications.

- If your pipeline will not be exposed to temperature loads, then in order to save, it is quite possible to use models based on low-pressure polyethylene. The fact that this type of polymer was used in the manufacture can be indicated by PE-RS, PEHD, PE or HDPE indices.

- The downsides of this material is the deformation when heated to 750C, low pressure resistance, as well as a tendency to loss of properties under the influence of direct solar best. It is for the latter reason that the instruction recommends that it is necessary either to protect the pipes laid in the open air with special covers or to hide them in closed trays.

Reinforcement thickness

Aluminum reinforcing layer performs a whole range of important functions:

- First, it prevents linear expansion of the pipe due to thermal deformation of the plastic.

- Secondly, it acts as a barrier to atmospheric oxygen.

- And, thirdly, the metal circuit provides mechanical protection, preventing damage to communications under external influences.

Today, companies produce modifications of pipes with aluminum reinforcement with a thickness of 0.15 to 0.75 mm.

When choosing, you need to take into account the following:

- The thicker the metal layer, the stronger the product will be.

- On the other hand, when doing their own installation without the use of special equipment, it is easier to bend pipes with a thinner reinforcing belt.

- Also, the size of the aluminum layer affects the thermal conductivity of metal-plastic pipes: the metal conducts heat well, therefore, more reliable models will have higher energy losses during transportation of the coolant.

Note! In any case, in this parameter, MP-pipes benefit from pure metal: for example, the thermal conductivity of copper communications will be 1200-1300 times greater.

Summarizing, I would like to note that from the point of view of specialists, the best metal-plastic pipes are products with a reinforcing layer from 0.3 to 0.5 mm. They are great for most jobs. But models with a very thin or, on the contrary, thickened metal layer should be used only when solving specific problems.

Nuances of production technology

Very important are also some points related to manufacturing technology.

These include primarily the method of joining an aluminum sleeve:

- The most qualitative are considered the types in which the edges of the metal strip are butt-welded. The thickness of the layer is uniform, which provides a significant increase in the reliability of the material.

- Cheaper models are produced by lap welding. At the same time, in the place of the lining of aluminum strips manufacturers reduce the thickness of the metal, which leads to the formation of a zone with lower strength. In most cases, it is along this seam that the pipe rupture line passes when the pressure is exceeded.

- It is also very important how firmly all the elements of the pipe will be connected to each other.. To assess the quality of this site, you must carefully inspect the fresh cut of the product, and try to break the integrity of the adhesive layers with the tip of a sharp knife or awl. If you succeed without effort, then the acquisition of this brand should be abandoned.

Note! Usually information about these and other features of the production contains a certificate for metal-plastic pipe. In principle, the very existence of this document is an indirect sign of acceptable quality, but it is better to study it in more detail - then you will definitely not lose.

Model Tips

Summarizing all the above, you can form such recommendations:

- First of all, we determine whether we really need this material. For example, when deciding whether copper or metal-plastic pipes should be bought, you should pay attention to thermal conductivity: copper is much higher, because they are better suited for heating, and metal-plastic will be more appropriate when installing hot and cold water supply.

- Secondly, carefully study the characteristics of the pipe. The optimal choice is PE-RT or PEX material, reinforcement from 0.3 to 0.5 mm, butt-welded, reliable bonding of layers. Everything that is outside of this list can be used for economy, but the quality of the equipped communications will be lower.

- Thirdly, we are determined with the manufacturer. No need to think that only imported products can be of high quality. In fact, experts have a kind of informal rating of metal-plastic pipes, in which leading positions include both domestic (Nanoplast, Valtec) and foreign (Oventrop, HENCO) companies. Moreover, Russian products are not only not inferior, but also surpass their foreign counterparts in a number of indicators.

After we fulfill all these recommendations, it is worthwhile to carefully inspect the purchased products themselves, focusing on the quality of surfaces and the reliability of the combination of aluminum and plastic. Marriage is even among world-famous manufacturers, so it is in our interest to identify it in advance.

Conclusion

The range of metal-plastic pipes available in the trading network is extremely extensive. That is why, even before going to the store, it is necessary to decide on the parameters of the products we need, that is, to choose not only the section and the required length, but also the material, the thickness of the aluminum layer, etc.

Armed with this information, we will spend much less time on the purchase of suitable parts, and we will provide our communications with the necessary safety margin.

Additional recommendations for assessing the quality of MP-pipes can be found on the video in this article.