Which pipes to choose for the well

The issue of ensuring uninterrupted and autonomous water supply of a private household is one of the most important. Today, thanks to the development of technology, it has become possible not to be so tied to external conditions, but with the help of a well device to have as much water as necessary. However, this will inevitably raise a number of related issues, one of which is which pipe to choose for the well and what should be guided by this. This will be discussed further.

General moments

In order to choose the right pipe for a well, it is necessary to take into account a number of common factors that influence this choice. And above all, we are talking about the depth from which water will be taken. It is practically established that the greater the depth of the well, the greater the load placed on its walls during the displacement of the soil.

The value will have and the way in which the water will rise to the outside. Or rather, we are talking about the type of pump used. If it is decided to use a submersible pump, then, for obvious reasons, the diameter of both the well itself and the casing will be larger than when the surface pumping station is activated. And this in turn will have an impact on the material of manufacture of pipes.

No less important circumstance affecting the choice of pipes for the well are the properties of the soil in which drilling is carried out. The less it is prone to bias, the smaller the thickness of the pipe walls will be required. Although these figures will not differ too much, with the right choice of pipes you can save a little.

Tip! If a pipe becomes clogged, for example, with sand, then when cleaning it, the inner surface of the walls will be subjected to quite serious loads, and not every material used for the manufacture of pipes can withstand it.

Types of pipes

Speaking about which pipes are most appropriate to choose for well equipment, it is necessary to say a few words about what they may be. We are talking about the material used for manufacturing.

Asbestos cement

Asbestos cement pipes can be successfully used in the process of well equipment. The existing opinion that this material is not entirely desirable and even harmful to human health is unjustified. Asbotsementny pipes possess rather good operational characteristics. They are durable due to their corrosion resistance. The material is chemically neutral, which can also be considered a plus. In addition, asbestos cement is quite cheap. The combination of these factors could make this material the undisputed market leader, if not for one sufficiently significant drawback - fragility.

Tip! When working with asbestos-cement pipes, it is necessary to exercise maximum caution, and therefore not every company undertakes work, and if it does, it is immediately reflected in the estimate. In addition, if the pipes need to be cleaned, this work is unlikely to be possible.

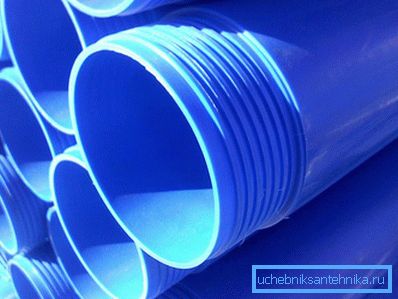

Plastic

The development of the chemical industry made it possible to use plastic for the production of pipes for wells. There are several types of such pipes on the market that differ in the type of plastic used:

- Unplasticized polyvinyl chloride.

- Low-pressure polyethylene.

- Polypropylene.

In terms of performance, these materials are similar. Among the most significant ones, it is possible to distinguish their safety for health, immunity to moisture, the possibility of providing a completely hermetic connection, ease of operation and lightness of the material. In addition, plastic pipes have a relatively small weight, which ensures ease of transportation and subsequent work with them.

Tip! As a minus it can be mentioned that such pipes, due to their small mechanical strength, can be used only when the well has a depth of less than 60 m. Although in some cases more is not needed.

Metallic

Along with other options, one of the most common materials for the manufacture of pipes for wells is metal, or more precisely, steel. It is necessary to add that there are several production options:

- Enamelled tubes.

- Galvanized pipes.

- Stainless steel pipes.

As for performance, the third option is out of competition.

Tip! Enamel coating is extremely unstable to mechanical damage, which complicates the work, and therefore increases their cost, and zinc oxide generally adversely affects health.

"Stainless steel" has good strength and corrosion resistance, and hence the durability of use. The disadvantage can be considered a fairly high price of the material. But after all there are disadvantages in everything.

Summarizing the above, we can add that it is necessary to decide which pipes to use for the well, based on the specific situation and the upcoming tasks. To make the only correct choice, you can consult with experts, but the general nuances are indicated.

Video

Find out what danger galvanized pipes are: