How to connect the boiler to the water supply: installation

In order for the house to be a place of rest, it is important that the living conditions be comfortable enough. It is almost impossible without hot water, which allows you to maintain personal hygiene and maintain overall cleanliness. Acquisition of a gas column is always a great solution, but in some areas their installation is simply impossible.

The principle is one, but there are many types of water heaters.

The boiler is a device for heating and preserving hot water. Sources of heat can be various elements. All heaters can be divided into two main types:

- With a storage tank.

- Flowing.

The design of the first provided for the presence of capacity. It can be of different volume. In order for the temperature not to fall over a long period of time, there is insulation between the inner tank and the outer panel. Usually it is made of polyurethane foam. The greater its thickness, the longer the water will remain hot. The second type is designed for instant hot water. It has a smaller size, and its design provides heating elements of greater power, which provides rapid heat transfer. As a rule, both in the first and in the second case, the user has the opportunity to adjust the temperature to the desired one. Thermostat control can be both electronic and mechanical. This does not affect the performance, only the convenience, the final cost and the cost of subsequent repairs.

All storage boilers are divided into:

- direct heating;

- indirect heating;

- combined.

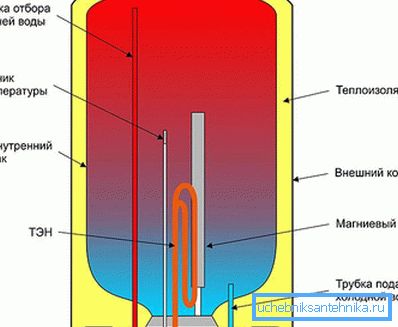

In the first case, inside the tank there is a heater, which provides the heating of the liquid. Some models have two or more. They can be switched alternately or simultaneously to ensure ultra-fast warm-up. Cold water is supplied through the nozzle, which is usually located at the bottom. The discharge is carried out through the exit, which is near, but inside the tank it is longer and reaches almost to the top, where the hot water rises.

Near the heating element is a magnesium anode. This is a small metal rod that prevents scale formation on the walls. The advantages of this solution are ease of installation, as well as the absence of the need to coordinate the installation with various services. Tanks can have both horizontal and vertical location.

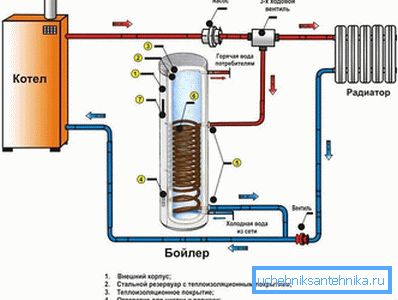

Indirect heating boilers are usually built into the heating system or function in conjunction with solar systems (special panels, the coolant in which is heated using solar energy). Structurally, it is exactly the same tank as the first type, but the insulation usually has a greater thickness. Also in them is absent TEN. Heating is carried out thanks to a coil, through which they let the heating circuit or from another system. They can be mounted both on the wall and on the floor (for tanks with a large capacity).

The design has a special inspection window, which makes it possible to carry out maintenance. In addition to the inlet and outlet, there may be two more. Their purpose - the organization of the recycling system. A separate circuit is created, along which the hot water from the tank constantly moves. This is necessary to ensure constant mixing of the fluid layers inside the drive, as well as to compensate for the distance to collapsible systems. In some cases, until the water reaches, most of it remains inside the system, or it loses its original temperature. Typically, the manufacturer laid the possibility of installing a heater, which turns this subspecies into the one that will be described below. The advantage of this solution is the maximum use of efficiency of the heating system.

Of the minuses, we can note the complexity of the installation, as well as the impossibility of using it in the summer period without an additional heater.

Combined systems have combined all the best of the above two options. There is also a coil for indirect heating and heating elements. The latter can be activated when the power of the heating circuit is not enough, or in the summer, when there is no heating at all. The disadvantages of such systems are quite complicated setup and some capriciousness in maintenance. Also, he will have to find a suitable place, because dimensions are great.

Tip! In some types of indirect heaters there are several coils. They either make it possible to connect several systems to release heat, or one of them is designed to use running warm water.

What to choose

If you find it difficult to make a choice, then you need to analyze the following points:

- Where is the installation of the heater planned? If the heater is purchased for a private house in which there is an autonomous heating system, then it makes sense to think about purchasing an indirect heating boiler. It is easier for him to find a separate installation site. The volume will be limited only by the allocated space. At the same time, one appliance will be enough to provide all water points. For small apartments, where space is limited and there is only a shower cubicle without a bathroom, it makes sense to think about a flow heater. It does not take up much space and provides quick heating. In other cases, suitable electric storage boiler.

- How many people live in the same house? From this will depend on the power and volume of the device. Do not think that the greater the capacity, the better it is for the end user. In fact, this approach can result in irrational waste on electrical energy. After all, in fact only 50 liters can be used, and 200 are heated. For one inhabitant, a tank of 30 liters will suffice. This volume is enough to comfortably take a shower, wash the dishes and wash in the morning. For a family of 2? 3 people need a device for 50-80 liters. In this case, everyone can take a shower with a small interval. There is enough heated water for kitchen needs, etc. If there are 4 or more people, then you need to look towards a tank with a capacity of 100 or more liters.

- For what purposes will the device be used mainly? In some cases, it makes sense to delimit the areas of consumption of hot water. For example, most often hot water is used to wash dishes and wash. For these purposes, you can put a separate boiler of a small capacity - 10? 20 liters, and include a larger heater in cases when there is a need to take a shower or a bath. For the first ones, special types with top connections have been developed, which are mounted directly under the sink and do not take up much space.

- Is there an autonomous heating system? If it is not, then you need to look to the side with electric heating elements. Except when there is a separate heliosystem.

- What is the condition of the electrical wiring? This is an important factor that can affect the selection of power TENA. Most often, the design provides electrical heaters with a capacity of 1.5 kW for large volumes? 2? 2.5 kW. For consumers with 3 kW and more, a separate supply is required. Also, be sure to take care of the presence of grounding.

- Will the walls withstand the planned load? A 80 liter boiler can weigh up to 20 kg, which means that when filled with water, it will weigh 100 kg or more. For loose construction materials, this is an unbearable burden. In such cases, it may be necessary to install through the hardware or install a special metal plate that will distribute the load.

Tip! Additionally, when choosing, it is also necessary to take into account the structure configuration The boiler does not have to be cylindrical, as we used to. Modern solutions also have Slim options, in which the diameter is reduced to the minimum possible size. In addition, there are rectangular devices. More specifically, several smaller cylindrical tanks can also be located inside, but the outer shell has a different shape. For such products it is easier to choose a place for installation, they also take up less space.

Electric heaters can also be different. The most common in the use of heater - tubular electric heater. It is in direct contact with water, like a boiler. For this option, grounding is required to eliminate all stray currents. More progressive is the dry heating element. In this case, special tanks into which a heater is inserted are embedded into the water column. It transmits the temperature not directly, but through the "mediator". This solution is more reasonable from the point of view of suitability for repair, since do not have to remove the tank, empty it and remove the bottom cover. It will be enough just to get access to the heaters.

Preparation for installation work

Before you start work, you will need to prepare a tool:

- perforator;

- drill diameter required

- dowels and hooks;

- cable suitable for cross-section;

- roulette wheel;

- drill;

- 2 adjustable keys;

- building level.

The fittings that will be required will depend on the specific types of pipe, this will be discussed later. Decide on the installation site. It is better if it will simply supply electricity, and it is also good if the water distribution is close, so there will be less loss on the way from the source to the mixer. If the external tank is made of ordinary steel, then the room should not have a constant high level of humidity, because This will lead to corrosion. It is desirable to maintain a constant positive temperature inside. Otherwise, it will be necessary to ensure that the scheme provides for protection against freezing, which will automatically turn on the heating element, taking into account the surrounding conditions. It is also necessary to analyze the condition of the walls, as described above, and to purchase additional strips.

Tip! The electrical circuit for connecting the boiler must necessarily include a safety device. It will catch the slightest current leakage and stop the flow in a timely manner, which will prevent the user from being defeated.

General moments

Regardless of which pipe you need to do the sidebar, there are a few basic points that must be observed in any situation.

- Before starting any action, the flow is blocked to prevent flooding. Usually the valve is located in front of the water meter.

- If the heater is mounted on a wall, then two holes are drilled using a perforator. To calculate the correct distance between the centers, you must first measure it on a plate that is welded to the boiler. Next, the labels are transferred to the wall and aligned in one plane with the help of the building level. Dowels are inserted into the holes and hooks are twisted or anchor bolts with a hook are immediately inserted. The tank is suspended, it must be taken into account so that the distance to the wall is not too large, because then the load on the fasteners will be higher. It should be level by level in a vertical plane. This can be achieved by using an adjustable stand, which is usually in the design, or linings.

- First of all, a detachable American-type connection is mounted on the boiler pipes. This is important because when servicing the unit, it will be much easier to disconnect it from the system.

- Next, install ball valves. You can not buy individual items, because There are locking mechanisms with an American.

- A non-return valve is installed on the cold water supply; it will prevent outflow when the liquid disappears in the overall system; a blasting valve will ensure that the excess is discharged during heating and expansion.

- There is another connection option. At the pipe supply of cold water is first wound tee. The tap for water discharge is connected to one of its branches. To the second - a blast valve and another tap that will overlap the total flow.

- Connect a hose to drain excess water.

- All threaded connections are sealed with tow or Teflon tape.

Tip! If it is known that there are pressure surges in the system that are more than what the boiler can withstand, then besides the check valve, you will also need to install a protective gearbox. His task will be the normalization of pressure to acceptable values.

Connection to metal pipes

In the apartment of the old house is usually used wiring from metal pipes. Connecting to them is in a sense troublesome, but not particularly difficult. If you can not connect to the outlet, then the main element that will be needed is a saddle. This is a metal clamp with rubber gaskets, which will provide a connection with the supply and exhaust system. It is necessary to select it for specific pipes, and the threaded connection should be on? ".

- Determined the best place for the implementation of tie-ins.

- Cleans paint to the width of the tie-in.

- The upper part of the saddle is applied to the pipe and the hole is marked.

- Next, you need to drill a hole on the marked label.

- The same actions are performed for the pipe through which the hot water will be discharged.

- At the prepared place mounted nurses. It is important to carefully install the rubber gaskets to avoid leaks in the future. The lower part is substituted and securely fixed with bolts.

- The final step is to connect the tie-in and the boiler with the assembled set of additional equipment. For this it is better to use a flexible stainless steel hose.

Tip! Another option would not be using a tie-in, but using a tee. For this, with the help of the grinder, a small section of the pipe is cut. A thread is cut from two sides with the aid of a meter, a tee is mounted and a connection is made with a flexible hose.

Connection to a metalplastic pipe

To carry out these works, you will need two tees for a metal-plastic pipe. If you plan to connect them with a boiler using a flexible hose, then they need to be taken with a transition to the thread in? ", If the supply is planned with the help of the same pipe, then it should be output 16 mm. In addition, you will need to buy a transition from a metal-plastic pipe on the threaded connection.

- Select a place for the implementation of tie-ins.

- It is marked according to the size of the tee minus the part of the pipe that goes into the connections.

- With the help of special scissors cut a small area.

- Unscrew the nuts from the tee and together with the locking rings are put on two nozzles. This is important to do now, because then it will be impossible.

- Pipes on both sides are flared with a special device. You can also use an ordinary screwdriver for this.

- Inserted tee. Pipes sink to the stop. Two rings are shifted, then everything is clamped with nuts with a wrench.

- If the tee was with a threaded connection, then the connection is made using flexible hoses, as in the first version.

- If the supply is planned with a pipe, then two segments are cut, the size of which will be equal to the distance from the tee to the adapter.

- Adapters are mounted to ball valves.

- Pipe sections are mounted in tees and adapters.

Tip! Fittings are also used for metal-plastic pipes, which need to be pressurized. In this case, the sequence of actions will be the same, but you will additionally need a tool for crimping.

Connection to polypropylene pipes

Additionally, you will need a soldering iron for plastic pipes, special scissors, two tees, two adapters for a threaded connection (MRN or MRV, everything will depend on the thread with which the taps and safety valves are installed), as well as the corners - their number will depend on the configuration plumbing.

- Select a place to connect.

- The pipe is cut to the width of the tee minus 2 cm. Approximately 1 cm will be sunk into the tee on each side.

- With the help of a soldering iron, the pipe and the fitting are heated, after which they are interconnected. After articulation, they can not be twisted, because it will lead to poor tightness.

- Further, with the help of pipe sections and corners, the liner is laid to the boiler pipes.

- At the end soldered coupling with a metal thread.

- Everything is securely connected and tightened.

Tip! It is good if several flasks with fine filters are installed in front of the boiler, as well as a salt filter - it softens the water and reduces the amount of deposits that can accumulate on the walls and the heating element.

Indirect water heater

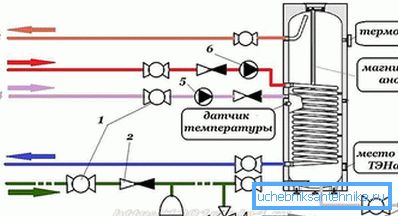

The system of supplying pipes will be the same as for the electrical version. But there are certain nuances of how to properly organize the contour of the heating system.

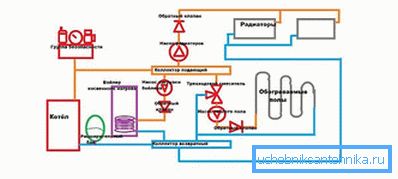

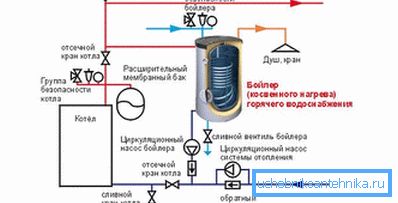

The first scheme involves connecting with the presence of a locking mechanism for 3 turns. The bottom line is that the temperature on the thermostat is set lower than on the boiler thermostat. Water coming from the heater goes to the heating system. As soon as the water in the boiler heats up to a predetermined temperature, the valve cuts off the flow to the heating and releases water into the tank. Thus, priority is given to the DHW unit.

The second includes the presence of two pumps forced circulation. One, as usual, is located on the return pipe of the heating system, the second is also on the return pipe, but already the one that comes from the boiler coil. Their work is controlled by a thermostat. As soon as the temperature in it drops, the storage pump starts, and the one that circulated around the entire heating circuit turns off, and vice versa.

The third method will be useful if the house uses a radial heating wiring system. It has a collector from which hot water from the boiler can flow both to the hot floor and to radiators. In such a system will be required to install the hydraulic arrows. It will compensate for the difference in pressure that will exist due to the functioning of several pumps for individual circuits.