How to cook electric welding

When carrying out construction work, it is often necessary to connect the disparate metallic elements together. One of the most reliable and familiar options for the implementation of the task is to conduct electric welding. With proper skill and experience, the result is an almost monolithic compound that will last more than one year. How to cook, we will tell in this article.

Where to begin?

Before proceeding to the description of the work, it is necessary to tell in general about the essence of the electric welding process, since the success of the actions will largely depend on an understanding of this issue.

Electric welding of metals consists in the fact that the elements are joined under the influence of point heating, as a result of which the metal of the two parts being joined is melted. The molten metal is mixed and after solidification forms a strong compound.

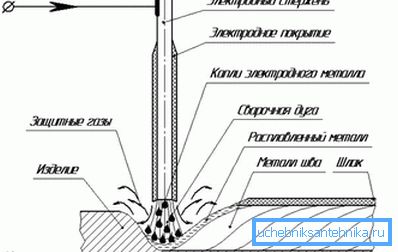

The bottom line is that electric current is applied to the electrode. At the time of bringing it to the parts to be joined, an electric arc arises, having a high temperature. As a result, the metal of the parts to be joined and the electrode material melt. After the occurrence of the arc, the electrode must be kept a short distance from the part to be welded. At the same time, forming a protective film, slag appears, which resists the premature and uneven cooling of the weld pool. At the end of the work, this slag is scraped off, and you can see the resulting welding seam.

Rules of work

If everything is clear with the theoretical side of the question, one can proceed to the attempts of welding. Immediately it should be noted that high-quality seam will not be immediately. Initial experiments are best carried out in the presence of an experienced specialist and when performing not very important work. The fact is that the quality here directly depends on experience. Even fully understanding the theory, it’s not all the time to weld the seam correctly the first time. However, there are certain rules according to which the work should be carried out:

- compliance with safety regulations. Welding is associated with the risk of injury from electric current and thermal burns. All actions should be carried out only in special protective clothing and subject to grounding. In addition, welding produces very intense ultraviolet radiation, and therefore work cannot be carried out without adequate eye protection;

- the parts to be welded must be fastened as tight as possible. During welding, the displacement of parts is unacceptable, as this will adversely affect the quality of the seam;

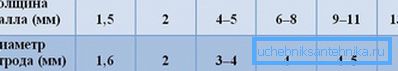

- the thickness of the electrode used in welding is directly dependent on the thickness of the metal of the parts to be welded;

- it is necessary to conduct the electrode over the parts being welded evenly. Do not allow excessive ruptures and sticking of the electrode. In case of interruption of the seam, it is necessary to stop the process, clean the seam and, retreating 1–1.5 cm from the edge of the interruption, continue working;

- The slag that pops up in the process of work should not be removed immediately, but after the work it is necessary to do this.

Immediately remove the slag is dangerous, as it scatters in different directions, it can lead to injuries and even fire.

As mentioned above, the choice of the thickness of the electrode should be carried out on the basis of the thickness of the metal. This can be schematically expressed in the following table:

The information has been established experimentally and is rather approximate, but it is possible to catch a certain regularity.

Welding process

As for the process of welding, it happens as follows:

- First, the parts are fixed and placed close to each other.

- The electrode is inserted and the welding machine is connected.

- The electrode is brought at a distance of about 5 mm from the metal surface, as a result of which an electric arc should appear. If it occurs earlier, then the current should be reduced, and if later, then increase. If you have an old welding machine, the arc will have to be ignited by touching the surface of the metal to be welded.

- When a stable arc is obtained, the electrode moves smoothly along the connection line, as a result of which welding is performed.

- After work, the seam must be cleaned from the crusted slag crust, having upholstered it.

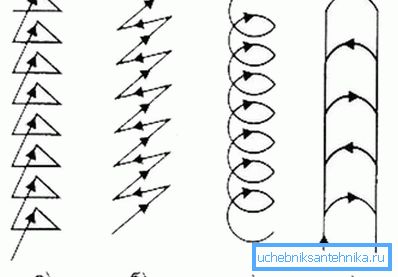

We should also consider the issue of the trajectory of the electrode movement relative to the welding line. Here it is important to understand that in the process of operation the electrode does not move invariably. Based on the specific conditions, oscillatory movements relative to the axis of the electrode (to hold the electric arc), vertical movement of the electrode vertically and oscillatory, arc-shaped movements to regulate the width of the seam should be present. The formation of the weld is made by combining these multidirectional movements, which you can see in the figure. As mentioned above, a complete understanding of the issue comes only with experience.

In conclusion, we can add that it is quite possible to master the technology of household electric welding, but to do really high-quality work it will take more than one hour of training and specialist guidance.

Video tutorials: how to cook by electric welding

The author of this video is a mechanic who learned how to cook by electric welding. Watch this video carefully: