How to cut the thread on the pipe

When performing a variety of repairs related to the restoration of water supply elements, the replacement of plumbing devices, heating registers and other things, it is necessary to use parts of steel pipelines with threaded sections. In this article we will explain how to cut the threads on the pipe yourself. If you know the features of cutting and stock up on the appropriate tool, then you will perform this task qualitatively and relatively quickly.

Pipe cutting features

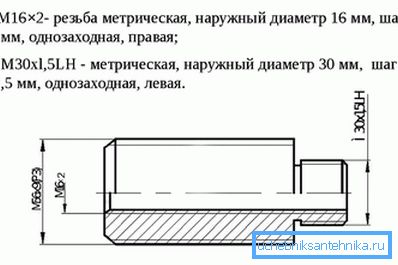

It has long been used for cutting threads on tubular elements not metric, but the so-called inch thread, which differs from the usual other angle of the thread profile (55? against 60? in metric). In addition, inch thread has a smaller pitch value, which is explained by the small thickness of the pipe wall.

A small pitch means that the threads of the threads will be longer on the same length of the thread. Accordingly, the reliability of the connection increases.

The thread is right and left. When looking at the right-hand thread, when viewed from the end of the product, they go to the right, and accordingly, at the left, to the left. Much more often used right-handed thread.

Determining which thread on one of the threaded sections is very simple: if, when screwing the abutting element, it turns clockwise, it means that the thread is right.

On a water pipe, the direction of the turns does not matter, since the products after the connection do not rotate, but remain stationary. In addition to pipe threads in connections, fastening threads are also used, whose pitch is larger. It is performed on hardware and holes for them.

Methods of threading on pipes

The thread on the water pipes can be cut with your own hands with the help of two tools - dies (it is also called Lerka) and a screw die. What is the difference between them?

The die is a manual thread-cutting tool, the outer side of which has a seat under the body in the form of two oppositely spaced grooves. And the inner side is a plate with a threaded hole and flutes for chip removal, reproducing the diameter and pitch of the required thread. At the end of the threaded profile there are so-called junction areas. They perform a dual function: provide ease when centering sections of two pipes before connecting them and improve the yield of chips formed during threading. On the end surface of the die is applied the designation of the diameter of the thread. For cutting the die is inserted into the housing-driver, supplied with removable handles for turning the dies, and fastened with screws.

How to cut the thread properly? It is better if the pipe being cut is securely and evenly secured in a metal vice. The slightest bias will lead to the fact that the thread will be cut with a slope. This will lead to the weakening of the pipe wall and the skewing of the entire connected section of the plumbing or plumbing system.

To ensure reliable direction should be a small revision of the plate. To this end, a guide bush is welded to one of the ends of the die, which should enter the pipe with a small gap (no more than 0.2–0.4 mm) where the thread is cut. The length of the guide sleeve must be at least two diameters of the cut thread.

Klupp - a more professional thread-cutting tool (for sale is usually a set of several hugs of different diameters). The principal difference of the screw die is that its dies are sliding and consist of four halves, therefore they can be adjusted to cut threads of different diameters, but in one single step. When fitting the die into the pipe section, the dies are brought to the surface and secured in the desired position. Adjustment of the relative position of the split dies of the die is made by moving its plan-washer.

The screw die already has a guide element in its design, so there will be no skewing of the thread being cut when it is used.

A more practical kind of humps is considered to be a ratchet, in the construction of which a ratchet mechanism is provided. Threading is made not by rotational, but by swinging movements of the handles with simultaneous feeding of the die. Klupp irreplaceable if you want to cut the thread on the pipe, without removing it from the pipeline section.

Cutting technology

The sequence of threading on the pipe consists of the following steps:

- They clean the required section of the pipe from rust, paint smudges and other irregularities of the external diameter of the pipe.

- Liberally lubricate the desired section of the pipe with machine oil or sulfofresol, so that the load on the handle when cutting will be much less. The same can be done for the dies / dies.

- Securely clamp the pipe in a vice. In this case, the end of the pipe protruding for cutting should not be more than 5–8 of its diameter, otherwise the accuracy of cutting is not guaranteed. Dies with a guide bushing or a screw plug do not require such restrictions.

- The pipe is prepared for cutting, for which a lead-in cone with a height of at least half the height of the die is obtained by a file. A running section of the thread is formed in this area, if it is critical, then it can be removed with a hacksaw.

- Put a die or a die, and, vigorously turning the knob, get the required threaded section. It should be remembered that the length of the cut thread should be a few more turns required. For fidelity, you can drive the plate over the cut section several times.

So, if you follow the instructions and recommendations suggested in the article, you can quickly and accurately cut the threads on the pipe. Do you have any questions on the topic? Then ask questions by writing a comment on the article.

Video

Maybe you prefer to see once than to read the technology of cutting the pipe many times? Then this video footage will be especially helpful to you: