Pump control cabinet

The pump control cabinet is the brain of the autonomous water supply system, it allows you to control their work. Thanks to its installation, equipment operation is prolonged and energy is saved. The cabinet is the place where all control and safety units are assembled. Such blocks are formed for water supply, sewage, fire extinguishing, heating systems.

Purpose

In the closet are placed compactly the controls of several engineering systems: water supply, its discharge and drainage. In the distribution structure, there are installed blocks that control a downhole submersible pump, which ensures the functioning of water supply and heating, and a drainage one, which is used for automatic pumping of water. All elements of control and switching are protected by metal walls from external influence. The functions of the device include:

- Organization of manual and automatic control mode, protection of pumps against short circuits and limit overloads, exceptions of incomplete phase operation mode.

- Monitoring the main parameters of the water supply system: water level, pressure in pipes, temperature and other data that affect the stability of the pump. Informing about the status of working mechanisms.

- Smooth start and stop of the electric motor.

- Breakage protection.

- Reduced power consumption.

- Adjusting the change of pumps in the event of an accident and the exit of one of the system.

- Alert an alarm using the dry run relay signal.

- Implementation of work in sleep mode, when there is no water analysis.

- When controlling several pumps, the working unit is periodically changed, which makes it possible to even out equipment wear.

The principle of operation of the cabinet involves the inclusion of a pump motor when a signal arrives at the sensor, in coordination with the control unit, the operating mode is set. The control can be carried out in manual mode using buttons and in automatic mode. The second option is the main one.

Standard equipment

Control cabinets for all types of pumps have the same configuration:

- The body is a metal box containing electromechanical equipment.

- Phase control unit - three sensors that report the operation of each phase. It is placed in front of the hardware.

- The front panel - the Start and Stop buttons are installed on it, pump and relay operation indicators switch the automatic mode to manual.

- Fuse - Relay, triggered during a short circuit. The device has a melting element, which burns at high voltage and opens the circuit, protecting all equipment of the cabinet and the winding of the electric motor from damage.

- Contactor - is a switch that provides energy to the pump terminals, and disconnecting the device from the voltage.

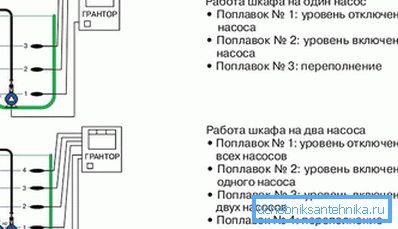

- The control unit controls the operation modes of the pump. The terminals of its sensors are in the well or tank, and in the case of a drainage pump - in a septic tank. A set of sensors - reducing and raising the water level and overflow, gives the command to turn the unit on or off.

- Frequency converter - provides a smooth start and stop of the asynchronous motor, regulates the rotational speed at the initial stage and at the moment of shutdown.

- The temperature and pressure sensors are connected to the contactor, their readings do not allow the unit to be turned on in unacceptable conditions - at negative temperatures and high pressure.

Cabinet dimensions depend on the number of control equipment and assigned functions. The massive construction has a floor execution, and in a compact size the cabinet is fixed on the wall.

Types of devices

There are several types of pump control cabinets available:

- with direct start - the devices are compact and easy to manage, turn on and off the required number of pumps, perform automatic change of units;

- with one frequency converter - smoothly regulate the engine speed, reduce energy consumption;

- with soft start device - they provide protection of units against mechanical overloads, water hammer and starting current;

- with frequency converters installed on all engines (from 1 to 5) - supports operation parameters according to sensor readings, connects backup pumps in automatic mode.

Service

The manufacturer supplies the equipment with a technical passport and instructions. Before turning on automation, you should familiarize yourself with the scheme and recommendations. Maintenance of cabinets consists in cleaning the ventilation filters, replacing worn parts, tightening the contacts and mounting screws. The fan and radiator of the converter need to remove dust. In case of serious damage, warranty service is performed.

All maintenance work on the cabinet is done with the power off.

Video

See how you can make the pump control cabinet on your own by spending just 30 minutes on it:

AlfaTech displays its control cabinets for pumps and talks about them: