The pipe bender for the profile pipe itself

When constructing a greenhouse, working on a garden plot or laying a pipeline, it becomes necessary to bend a pipe or a metal strip at a certain angle. For these purposes, there is a special tool - pipe bender. You can buy it in a store or make a pipe bender for a profile pipe with your own hands. Such a device is capable of bending products made of aluminum, copper and steel.

Species

Device models differ in the principle of operation:

- The smallest power is hand tools that can bend a pipe with a minimum diameter.

- Larger products will require hydraulic drive forces. This model is used by professionals and allows you to perform a significant amount of work in a short time.

- The pipe bender with the electric drive is manufactured in stationary and mobile option. With it, you can bend pipes of different diameters, and the manual model is configured only for one size. The use of an electromechanical tool guarantees an exact bend angle and does not cause deformation of the pipe profile.

Impact methods

- Winding - the pipe is attached to the bending roller, which reels it on itself, creating a given angle.

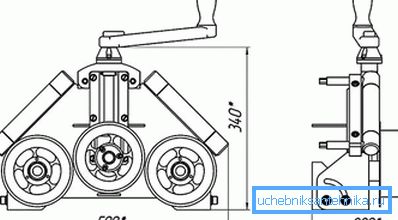

- The arbalest method - the pipe rests on two stationary rollers, and the third one presses it in the middle.

- Rolling - the design has three movable rollers located in one plane. The central roller rolls and presses the product.

- Running in - the pipe is clamped on the template, and the movable roller rolls it around the contour.

Pipes cannot be bent to any angle, there are special directories in which admissible values are indicated for products with different cross sections and wall thicknesses.

Tool making

So, how to make a pipe bending tool? The simplest version of the manual pipe bender is made of wood. A template is cut that matches the shape of the bend product. Its thickness is slightly larger than the size of the pipe. Provide a reliable fixation will allow cutting out on the end of the beveled profile. The pattern is made of two bonded boards. The workpiece is firmly fixed on the edge of the table or workbench. Nearby is screwed wooden plate, which will serve as a focus for the pipe.

The process of bending aluminum or thin-walled steel profiled pipe is as follows - the end of the product is inserted into the gap between the template and the stop, taken at the opposite part and gently bend it. The pipe lies on the end of the wooden template. To make less effort, you can insert a metal rod into the product or put a larger pipe on top. With it you can perform the arch for the greenhouse. To accommodate a long pipe, the template is installed in an open space, for example, on a wall or fence.

By the same principle, the design is made of metal hooks. On the basis, the necessary radius is drawn and details are packed along the line. Their position can be changed for different pipe bending diameters.

Manual bending machine

To make a hand-held pipe bender, you must have (or draw the most) drawings and make the necessary parts for them. The design of the pipe bender provides a gradual bending of the pipe in a sparing mode for it. This device is used by professionals in order not to deform the product.

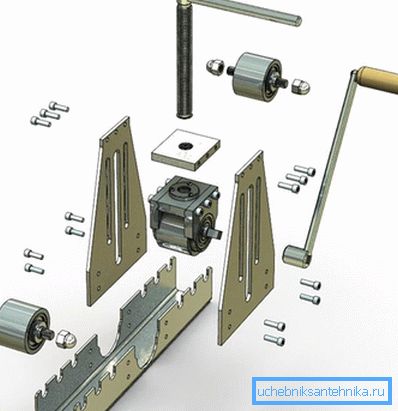

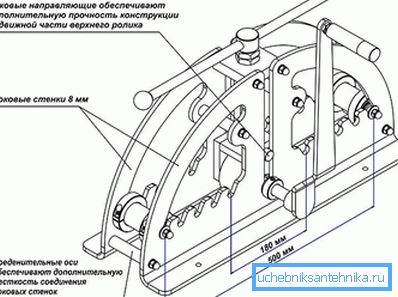

The frame for the machine can be made of metal or wood. It is easier to work with wooden parts, but they quickly wear out and have a lower productivity. Self-made models in which the pipe pulling is performed by rotating the center pressure roller, but it is easier to perform the machine with scrolling of one of the support rollers. If a chain drive is installed on such a design, then the efficiency will increase. For the manufacture of a simple design will require:

- Strong metal base, which is fixed on a flat surface.

- 4 rectangular plates are taken in which holes are drilled to fix the shafts.

- Screw fastening plates are connected to the base.

- Rollers of suitable diameter are inserted into the finished grooves. The shafts are attached with studs and nuts.

- The design for the installation of the clamping shaft, which deforms the pipe, is made of four shaped pipes and a plate welded from above.

- A hole is made in the plate for the installation of the screw, with which the central shaft will be pressed and raised.

- To fix the main shaft, you will need a U-shaped part, placed between the racks. In its side parts, holes are made to fix the shaft, and a screw is attached to the top plate.

- A handle for tube rolling is attached to one of the lower shafts.

There are a lot of options for the manufacture of pipe benders, they are distinguished by the complexity of execution. The video will help to deal with the nuances of performing complex work. If you do not have a welding machine and skills to work with complex tools, you can make a simple template bender.

Video

Check out a selection of videos that show how to make the most simple benders:

Schemes and drawings