Artificial stone sink - the main advantages and features of

Such an option as a kitchen sink made of artificial stone has become very popular in recent years, and this is due to a number of factors: from improving production technology and cheaper products to aesthetic preferences, because much more attention has been paid to the appearance of the kitchen.

Composite products combine a number of advantages, which we will consider in this review, will also touch upon the issue of the care and repair of sinks.

The main advantages of composite products

Let us see what properties of artificial stone sinks have and what advantages this option has over other analogues:

| Strength | Products made of composites have a very high reliability and durability. They are resistant to deformations and are able to successfully withstand most of the adverse effects. The only thing they are afraid of washing from an artificial stone for the kitchen is strong acids and alkalis, they can leave stains on the surface, and it will have to be polished. |

| electrical safety | Unlike the popular stainless steel, this material does not conduct electricity, which makes it much more preferable and allows you to install a kitchen grinder from the bottom. It is extremely not recommended to use dispensers with metal constructions. |

| Ease of care | You can clean the surface by any special means for the bathroom or sink. The main thing to keep in mind is that you do not use compositions with abrasive particles, they can leave scratches on the surface, in which dirt will subsequently accumulate; otherwise, taking care of a sink made of artificial stone is as simple as possible. |

| Hygienic | Due to the fact that the material has high hardness, there are no pores on the surface in which bacteria can accumulate. This allows you to constantly maintain perfect cleanliness without tedious cleaning. |

| Variety of models | This factor can also be attributed to the important advantages - there are a huge number of color solutions on the market, a wide size range and many forms, you can choose the option with two or even three bowls, a model with a working area on one or two sides, and much more |

Features of products from an artificial stone

Note! In order for the sink to serve you as long as possible, you need to select a quality option from a trusted manufacturer, the best thing is if there are customer reviews about the selected product, you can search them on the Internet if necessary.

As noted above, composite structures are distinguished by reliability and practicality. The manufacture of shells from artificial stone occurs with the use of crumbs of natural minerals (granite, marble, basalt, and much more) and an acrylic binder, which provides strength and durability.

What to look for when buying

The selection process should consider the following factors:

- The shape and size of the product, you should know in advance what parameters the sink should have, it depends on what countertop is used, where the sink will be located, whether there will be side working areas, etc. You can even get a countertop with a sink - this option has many advantages, although the price is much higher.

- The wall thickness should be at least 9 mm, usually this figure can vary and be up to 12 mm or even more in some models. But too thick walls are also undesirable, since the weight of such structures is very large, which creates inconvenience during installation and gives additional strain on the furniture.

- The surface must be uniform, free of pores and cracks. It is best to choose the options with semi-polished, since the gloss is much easier to leave scratches. External inspection is very important, since each unit is made independently, and the fact that the ideal sample is displayed in the display case does not mean that the box will be exactly the same.

Note! Be sure to read the quality documents. They should contain important data - from the grade of the product to the composition of the materials used. In the best examples, only stone chips and acrylic composite are included in the composition.

- If the installation and connection will be done by hand, the scheme, instructions for the work should also be. With the seeming simplicity, it is sometimes possible to miss the important nuances, so it’s best to always read the recommendations given by the manufacturer.

Repair recommendations

It is often possible to meet the question of those who have long acquired artificial stone sinks - do repairs do it yourself or do you need to involve specialists? In fact, the work on the forces of virtually any person, as long as the required devices were at hand.

In general, the following recommendations can be made:

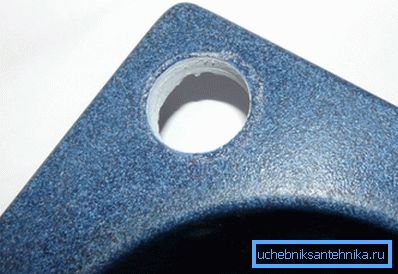

- Before drilling a sink made of artificial stone, you need to purchase a special carbide-tipped drill bit or a special crown with a diamond or tungsten coating. At the same time, you should choose quality products, since there are frequent cases of selling drills and crowns that wear out literally before our eyes.

- It is also important to carry out all the work carefully - starting with accurate marking and ending with reliable fixation of the sink during the drilling process, otherwise you risk to spoil the product.

- Now consider how to repair the chip on the shell of artificial stone. It is also quite simple here: it is necessary to purchase an acrylic-based adhesive composition and attach a fallen fragment with it. At the same time it should be pressed tightly so that the resulting seam was as small as possible.

- After the glue hardens, the surface at the repair site is carefully polished.. Most often, after this procedure, the repair site can not be seen.

Conclusion

Artificial stone is an excellent material for making durable and very beautiful shells, so it will be in demand for many years to come. The video in this article will tell some more important features of products made of composite materials.