Choose and install steel shower tray as one of the most

The shower cabin with the steel pallet is, perhaps, the most practical and durable kind of similar devices. In contrast to plastic and ceramics, steel well withstands operational loads, because it is often chosen as the material for the manufacture of sanitary products.

In our article we will tell you what metal trays for shower cabins are, how to install them correctly, and analyze their advantages and disadvantages.

Design features

Production technology

Products of this type are among the most sought after on the market. Even if we accidentally make a mistake and type in the search engine something like “a metal shower oddon 900x900 mm”, we still get a fairly extensive sample of tens or hundreds of models.

By itself, the steel tray is a relatively simple construction.

It is produced in the factory by stamping and subsequent processing:

- As a rule, steel sheet with a thickness of 1.5 to 3 mm is taken as the starting material.. The sheet is cut into blanks, the size of which allows you to make a container of appropriate dimensions.

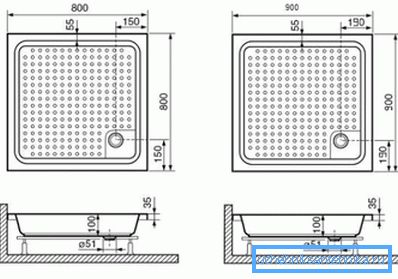

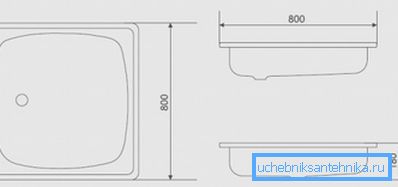

Note! Most of the models on the market are square in size and vary from 70x70 to 90x90 cm. Somewhat less large products are found, as well as rectangular pallets whose width exceeds the length (for example, 120x90 cm).

- Steel blanks are subjected to primary heat treatment, and then served under the press. At the same time, the sides of the pallet are molded in several stages, a hole is made for the drain, and a relief is applied on the bottom.

- After punching the edges of the sides and holes are cleaned., and then an anti-corrosion compound is applied to all surfaces. Most often it is enamel, but sometimes zinc-based passivating agents are also used.

- Also, in some cases, fasteners are attached to the pallet for mounting the legs and upper guides, used for fixing the shower enclosure.

Note! Models without legs are mounted on the side walls, which are most often welded to a stamped workpiece. However, such products have a drawback: they can be mounted only on a pre-leveled surface, while trays with legs allow for position correction.

The result is a fairly durable, reliable and stable product that is relatively easy to assemble and tolerates the most intensive operation.

Forms and varieties

As we have noted, most of the pallets are square or rectangular. Such products are relatively inexpensive, easy to manufacture and assemble. However, they are not very practical, since with traditional corner installation they take up quite a lot of space.

Angular models with a trapezoid or rounded front part are somewhat more expensive. They are more compact, and therefore they are chosen to be installed in small bathrooms.

Another parameter influencing the choice is the depth of the base. If you want to protect the bathroom floor from drops and splashes as much as possible, then a deep (up to 150 mm from the top edge of the rim to the bottom at the drain hole) pallet is ideal for you. But in the street shower, you can use small (up to 80 mm) models.

Also pay attention to the material from which the design is made. There are two options here, and it’s most convenient to compare them in the table below:

| Product type | Special features |

| Stainless steel |

|

| Enameled black metal |

|

However, whatever the anticorrosive protection of the metal from which the pallet is made, its effectiveness depends on the thickness of the base.

The reason is simple:

- Typically, these products have a sufficiently large area (80x80 cm and more), and are installed on a frame that is laid along the edges.

- When exposed to large loads, a thin (less than 2 mm) metal in the middle part begins to sag, and the insufficiently elastic anticorrosive composition becomes covered by microcracks.

- Over time, these cracks widen, resulting in peeling of enamel.

That is why experts highly recommend not to save on the purchase of thin pallets. Of course, the price they will have lower, but the service life will be reduced by an order.

Pallet Installation Technique

Required tools

Installing a steel shower tray with your own hands is not only quite possible, but also quite simple.

We will need such tools and consumables:

- For the model without legs - screed to level the floor.

- Branch pipe with a diameter of 50 mm to connect the siphon with sewage ..

- Special siphon, which is installed under the shower.

- FUM tape for sealing pipe threads.

- Sealant (it is best to use moisture-resistant, silicone-based).

- Roulette and level.

Tip! The pallet, purchased separately, must be measured in advance, so that all other elements that we will manufacture for the shower stall are suitable in size.

Mounting algorithm

Instructions for installing such products with your own hands suggests the following sequence of actions:

- First, check the floor level. The design of the legs can be fixed on almost any surface, but models with a massive base require alignment by pouring the screed.

Note! Since the screed gains sufficient strength for at least 7 days, it must be poured in advance.

- Next, you should collect the pallet. As a rule, before installing it, we need to attach legs to it, inserting them into specially made grooves and fixing them with fixing screws.

- We install the product in the chosen place, after which we attach a siphon to it to drain the water, sealing all the joints with rubber gaskets. It is most convenient to do this until the final fixation, while the pan can still be tilted.

- Conclusion siphon attach to the sewer pipe. Usually, a rubber cuff is used for this purpose, which allows you to quickly disassemble the system to eliminate sewage obstruction.

- Align the pallet by turning the screws on the legs. At the same time we make sure that the level of the drain does not fall below the level of the entrance of the siphon to the sewer.

- We carry out a trial drain by blowing water into the pan under a slight pressure. If there are no leaks anywhere, we finally fix the legs and install the side panels or revet the edges with tiles.

Advantages and disadvantages

Steel products have a number of advantages:

- Firstly, they are much stronger than acrylic and plastic models. So if in your family there are people with a weight well over 100 kg, then you will not find an alternative. The shower cabin of 800х800х1975 mm with the steel pallet is that minimum which is necessary to you!

- Secondly, most models are mounted in just an hour and a half. Of course, sometimes there are difficulties at the stage of leveling the base, but if you buy a structure with legs, then you can adjust its position by rotating several screws.

- Thirdly, pallets of this type can be used both as an independent sanitary device and as part of a shower stall. The second option, of course, is preferable from the point of view of comfort, but if you need to equip the shower with minimal financial costs, then just a pan with plastic curtains around the perimeter is enough.

As for the shortcomings, they are:

- Propensity to corrosion in case of damage to the enamel or the passivating layer in black steel.

- A limited number of design solutions.

- Significant volume of sound when falling jet of water.

However, we can compensate for the last minus by applying a layer of foam before installation on the wrong side of the pallet. With the rest of the flaws it is possible to put up, properly exploiting the structure and avoiding damage to the anti-corrosive layer.

Conclusion

The various sizes of steel shower trays, presented in specialized stores, allow you to choose a product for almost any bathroom. Well, having found a model that is suitable in terms of dimensions and other parameters, we will need to install it correctly. And here will help the above recommendations from experienced masters, as well as informative videos in this article.