Countertop under the sink: the manufacturing process

Creating the interior of the bathroom, the owners of houses or apartments try to use special materials for the installation of products such as a sink or bathtub. In this case, most often there is a need to create work surfaces on which you can place personal hygiene items and household items. That is why the tabletop is usually created under the sink in the bathroom with his own hands, if there is no shop-building design for solving such a problem.

Manufacturing process

To begin with, it must be said that such an operation is performed not only for beauty, but also to give the structure a good appearance. Given this, the master, talking about how to make the countertop in the bathroom under the sink, is advised to acquire the simplest sinks, since the additional elements in the form of racks will only lead to costs. Therefore, it is not necessary to purchase such Tulip type sinks.

Material selection

First of all, all the elements that will be used for this work must be highly resistant to a humid environment and direct contact with water. Therefore, it is best to use the same materials that are used to create a cabinet or frame, which will be the kitchen sink under the countertop.

Usually, plastic panels, moisture-proof plywood or fully laminated chipboard plates are used for these purposes. If boards or slats will be used for work, they should be treated with a special compound to protect against moisture. However, professionals recommend using metal profiles and special countertops, which are specially designed for this purpose, to create the framework, although their price is very high.

Tip! Sometimes it is much easier to purchase a ready-made sink with a tabletop and on racks than to create such a structure yourself. This will help get rid of the mass of hassles associated with the design and subsequent manufacture.

Installation

- First of all, make the installation of the bottom of the sink under the countertop. At the same time it is necessary to create a kind of frame on which the whole structure will be supported. All elements need not only firmly connected to each other, but also fixed on the wall.

It is also important to make a special substrate that will hold the shell itself from the bottom. In this case, fit a wooden board or plywood, which is cut to the shape of the sink.

- Pre-purchased material for the manufacture of countertops must be processed so that it appears seat for the sink. In this case, it is necessary to take into account the design features and model. Also, the level of immersion of the product in the structure will depend on this.

- It should be noted that with the independent production of such structures it is simply impossible to avoid the occurrence of gaps between the sink and the surface of the table top.. Therefore, the installation manual recommends the use of moisture-resistant sealants to seal such voids.

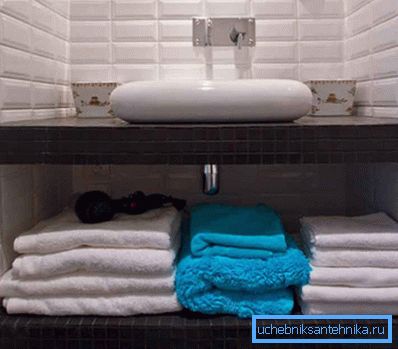

- Making such work, you should not be limited to the creation of the surface.. You can completely sew the lower part of the resulting original cabinet or install the hinged doors there.

Tip! Professionals recommend creating shelves or drawer cabinets under the sink. This will allow you to efficiently use the free space and hide some objects or things from sharing.

Recommendations of specialists

- Creating any design in the bathroom, you must remember that in this room there is a high humidity and constant temperature changes. Therefore, to work you need to use special materials or means for protection.

- If such a surface will be created after the purchase of a car wash, then this fact should be taken into account even before the purchase. You need to pick up such a product, the design of which allows you to install it in the hole and at the same time it can be kept on the edge with the help of the sides.

- Sewing up the sink, it is completely worth taking care to have convenient access to the pipes and sewage system. This will greatly facilitate the work during preventive maintenance or cleaning sewage. However, some masters believe that closing this area is generally not worth it, and to give it a good appearance it is better to get a beautiful siphon.

- When creating a drawing of a future product, it is necessary to take into account not only its dimensions, but also their ratio in the room. That is why it is worthwhile to additionally create a plan for the placement of all the interior items in the bathroom, indicating the scale and exact dimensions.

Conclusion

After studying in detail the video in this article, you can learn more about the process of manufacturing such structures. Also, taking into account the article above, it is necessary to conclude that in most cases the manufacturing process depends on the model of washing.

Therefore, this aspect must be considered at the design stage, before the acquisition.