Expansion tank for heating: types of equipment, open and

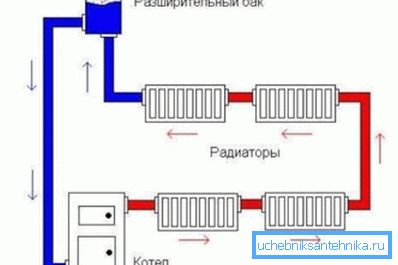

For the normal functioning of the heating system, not only the heating boiler, pipes and radiators are necessary. A minor role is played by the additional equipment: air valves, thermostats, valves and so on. Expansion tanks for heating are also important, due to which the required fluid pressure is maintained in the pipelines and excess air is removed. About why this element of the system is needed, how to choose a suitable model and install it yourself, read on.

Equipment types

The choice of this unit must begin with consideration of existing models on the market.

Modern technologies of arrangement of heating systems provide that the expansion tank in the heating system may be:

- open type - is a unpressurized tank, where at any time you can pour the used coolant, if necessary;

- closed type (membrane) - hermetic tank divided by a flexible partition: on one side of which there is a coolant, on the other - pumped air or special gas.

Open

The advantages of this type of equipment in its ease of installation and maintenance. An open expansion tank for heating does not require the arrangement of taps, a separation membrane and a hermetic cover that protects the interior from air penetration.

Compensation of losses of the coolant, inevitable in this case, is done in the simplest way possible: you need to pour water up to the required level with a regular bucket. Although many models have an entrance to connect the plumbing.

Capacity shape does not matter. This may be a flat metal box or a barrel, the volume of which is sufficient to accommodate the heat carrier displaced by heating.

Despite the fact that the price of such a solution is minimal, the open expansion tank of the heating system has several significant drawbacks:

- the need for continuous monitoring of the water level in the tank and its topping up;

- Difficulties in choosing a place for installation (installation instructions require its placement at the highest point, which is very difficult if the house does not have an attic room);

- low coolant pressure in radiators and heating pipes;

- metal corrosion - pipes, tanks, radiators, and so on;

- the need for insulation - in some cases, the coolant may freeze (especially if the attic of the house is not properly insulated).

Tip! After reviewing the listed disadvantages, ask yourself: do you need such a tank? In most cases, it is better to spend a little more money and buy a more advanced unit. It is somewhat more expensive, but the benefits will not make you disappointed in the decision made.

Sealed

Here we will just consider the membrane expansion tank in more detail: it may not be necessary for the gravitational-type heating system (although this statement is also debatable), but the climate network with forced circulation of the heat carrier usually requires the installation of this particular equipment.

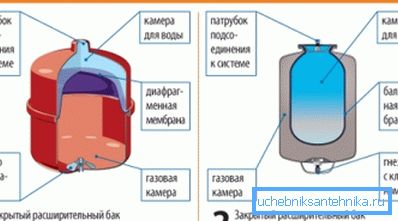

Sealed expansion tank of the heating system can be of two types:

- with food rubber diaphragm - such units are colored blue, cost less, but less durable and durable (the membrane can rupture if the pressure in the expansion tank of the heating system exceeds a certain level);

- with technical rubber diaphragm - these are better products, which are covered with red paint (to distinguish the models among themselves).

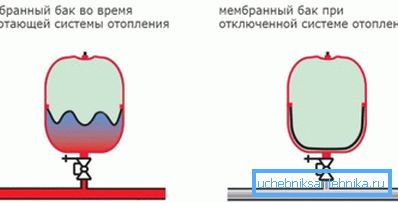

The principle of operation of the devices is the same and extremely simple: as the temperature rises, the coolant volume increases and its excess flows into the tank, compressing the air behind the membrane and increasing its pressure. As the water cools, the reverse occurs.

Depending on the method of fixing the membrane are distinguished:

- tanks with a removable elastic partition - in case of damage it can be replaced without dismantling the container;

- tanks with a fixed membrane - in this case, you will have to change the entire tank, which, however, costs much less than the previous version.

Expansion tanks for heating systems equipped with a flange (removable) partition have several advantages:

- withstand greater maximum pressure;

- can be mounted both vertically and horizontally;

- provide an opportunity to quickly replace the membrane in case of rupture.

Tip! To avoid damage to the septum, it is recommended that when the heating starts, select the minimum mode of its operation, then the system pressure will rise slowly. You can also install a valve with a pressure gauge, through which excess air or water is discharged.

Tips for choosing

Before choosing a particular type of tank for installation in the heating system, it is recommended that you familiarize yourself with the positive aspects of using a sealed expansion vessel.

It is unlikely that after this you will have any doubts:

- it is not necessary to install it at the top of the heating network, which makes it possible to save on the purchase and laying of pipes;

- a tank with a membrane has a smaller size than an open type tank;

- loss of coolant due to evaporation is excluded;

- heat losses that are inevitable with insufficiently insulated open containers are minimized;

- metal parts of the heating system are better protected from corrosion, as a sealed tank prevents air from entering the pipelines and radiators;

- the presence of a closed expansion tank allows you to operate the heating with an increased pressure of the coolant.

Tip! In addition to design features, pay attention to the name of the manufacturing plant that produced the expansion tank. Quality directly depends on it. The most famous products of the company Reflex, Zilmet, Aquasystem, Cimm. These expansion tanks for heating are well established in gravity heating systems and in networks with forced organization of fluid circulation.

Installation process

Selecting an expansion tank for heating and buying it is only half the battle. It is also important to properly install the equipment. From this depends directly on the effectiveness of its work, and durability.

The installation procedure is as follows:

- Ensure that the ambient temperature is above 0 degrees Celsius. Otherwise, work must be postponed until warming.

- Prior to the completion of installation, provide quick access to the air valve. This will allow you to quickly adjust the pressure in the upper (gas) part of the tank and prevent rupture of the membrane.

- After the installation is completed, access to the valves and drain valves should not be obstructed by any objects.

- The tank must be installed so that no pressure is applied to its external surface. In particular, make sure that the heating pipes do not touch the container walls.

- It is advisable to install an additional gear regulating fluid pressure. It will help to pry off excess coolant, thus preventing the destruction of the tank in case of emergency.

- The tank must be mounted on a segment of the pipeline that supplies the already cooled coolant to the heating boiler. However, not near the inlet of the latter.

Conclusion

Expansion tank, despite the apparent insignificance, is an important element of the heating system. It is precisely it that prevents its destruction as a result of an increase in pressure and prevents the formation of air plugs, which reduce the efficiency of work. For more information about other necessary elements of the climate system at home, you can learn from the video below.