How to make a manhole for sewage

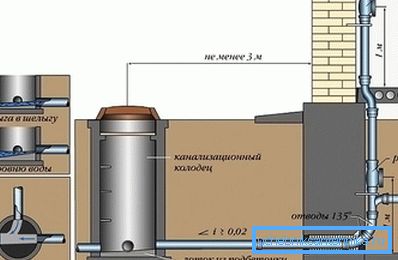

Today, almost all private houses have a local sewage system, but, as a rule, every sewer system needs constant monitoring and maintenance, and inspection wells are needed for this purpose.

Therefore, many owners of private homes are thinking about how to make this device on their own. But before you start working, you should consider their types and design.

Types of manholes and their design

Depending on their design, manholes are classified into the following types:

- Control - they are necessary for the inspection of pipes sewer system.

- Swivel - they set in those places where the direction of the pipeline changes.

- Drop-off - mounted where the pipe levels (inlet / outlet) do not match.

- Wash - necessary where the fluid flows slowly and a precipitate appears, in other words, the pipes need frequent washing.

- Linear - installed on the section of the direct pipeline.

- Nodal - mounted in places where is located the connecting node pipes.

Despite this diversity of species, they all have almost the same design. Each manhole consists of a base, tray, working chamber, mouth and hatch. At the same time, such wells can have various shapes, both round and quadrangular.

Independent construction

The construction of this device begins with the design. At this stage, a place for the well is selected and the territory is cleared. It is also worth deciding on the material from which the well will be made. Basically for the mine using plastic tanks or reinforced concrete rings.

Plastic container is the easiest option for arranging a well. In contrast to the reinforced concrete ring, this capacity has less weight, which greatly facilitates the installation of the well. In addition, plastic is also famous for its long service life and tightness.

Reinforced concrete rings are also durable and strong enough, but because of the heavy weight there are difficulties in delivery and installation work.

The procedure for the installation of a manhole from reinforced concrete rings

The entire installation process is divided into stages.

The very first stage, as described above, is design, selection of a place and its clearing. By clearing the area means the complete elimination of vegetation (trees and shrubs) and temporary buildings in the place where the installation of the well will be made.

The second stage is the construction of the pit. During the construction of the manhole, the excavation and cleaning of the excavation pit is made, the corners of the wall slopes are formed, and a certain depth is created according to the design. At this stage, as needed, the mine is also waterproofed. It is produced using bitumen mastic in the following order: first, crushed stone is spread evenly to the bottom of the excavated pit with a layer of 20 cm and is well rammed, then, crushed stone is filled with bitumen.

The third stage is the installation of reinforced concrete rings. At the bottom of the pit, which was prepared in advance, set (or pour) a slab of concrete. After that, create the tray of the desired shape. The inner walls and ends of the pipes are sealed with cement mortar or bitumen mastic. All this is left for some time for a good drawdown of the bottom, and then install the concrete rings themselves.

Like the inner walls, the joints between concrete rings are rubbed with cement mixture or bitumen mastic. Bitumen is mainly used in those places where you need a good waterproofing.

The next stage is the creation of a clay castle at the points of connection of the incoming pipeline. Such a lock usually has a width of about 30 cm and a height equal to the diameter of the pipe with the addition of 60 cm.

Then the inspection of the manhole and its final sealing is carried out.

Inspection of the well is carried out by keeping it filled with water during the day. At the time of this test, the pipes overlap with a temporary partition.

After a successful test, the well is filled in from the outside, where the ground is carefully rammed to avoid its shrinkage. It is also obligatory to fill the well mouth with a concrete blind area, which should be at least 1.5 m.

A little easier installation with the use of plastic containers, in this case does not require waterproofing the bottom and walls of the mine.